颜色是纺织面料视觉第一特性,承载表达文化、丰富情感的重要功能,也是体现时尚创意的关键要素。染色是赋予纺织品色彩的重要手段,但纺织品的染色过程也是资源消耗和污染物排放的主要环节。

活性染料和分散染料分别是纤维素纤维和聚酯纤维染色最常用的染料,二者产量占总染料产量的70%左右,2种染料染色新技术的发展是印染行业发展的重要组成部分。

活性染料的色谱齐全、色泽鲜艳、适用性强,通过与纤维反应形成共价键结合,具有优异的色牢度,但活性染料染色存在染料利用率低、无机盐使用量大、废水排放量多等问题,如何解决上述问题,已成为纺织印染行业的工作重点。

分散染料的水溶性不佳,需要加入分散剂来维持其在水中的分散稳定性,染色完成后,纤维表面未固着的染料颗粒需要通过还原清洗工艺来去除浮色,该过程能耗水耗大,且清洗残液中的分散剂、未固着的染料会加重废水处理负担,如何减少或免去还原清洗过程,提高染料的利用率成为分散染料染色技术发展的方向。

本文首先介绍了活性染料染色新技术,包括少盐/无盐染色技术、低给液高固色率染色技术、少水/非水介质染色技术、针织物平幅连续浸轧染色技术。之后介绍了分散染料染色新技术,包括碱性染色技术、液体纳米染色技术、免水洗连续染色技术、非水介质染色技术等。最后对结构生色技术的进展情况进行了简单综述。

1 活性染料染色新技术

1.1 少盐/无盐染色工艺

1.1.1 纤维素纤维阳离子化改性

利用季铵盐阳离子化合物对棉纤维进行改性,可将纤维对染料阴离子的库仑斥力转变为引力,增加染料在棉纤维织物上的上染能力,达到不用无机盐促染的目的。按照结合方式的不同,阳离子化合物分为反应型和非反应型2大类,反应型化合物包括小分子化合物和聚合物,非反应型化合物通常为聚合物。

Dong等[1]利用表面引发电子转移活化再生催化剂原子转移自由基聚合技术,将2-(N,N-二甲胺基)甲基丙烯酸乙酯通过接枝反应引入棉纤维,用于无盐染色,其主要作用机制是在弱酸性染浴条件下,被接枝到棉纤维上形成带正电的化合物,与活性染料产生静电吸引,促进了活性染料对棉织物的上染。利用活性红M-8B对改性纤维进行染色,上染率高达98.8%,染色织物的K/S值为45.2,远高于传统有盐染色织物(10.8)。Toprak等[2]利用氢键及偶极作用将4-乙烯基吡啶结合到棉纤维素大分子链上,赋予其正电性,通过静电引力与染料上的阴离子基团作用,提高二者的亲和力,可减少染色过程中无机盐的使用,用量仅为传统染色工艺的1/3,但染色效果与常规染色工艺相当。

阳离子改性剂中季铵盐结构的存在会降低染色织物的耐日晒牢度。为解决这个问题,大连理工大学张淑芬教授课题组[3]通过合成聚(丙烯氧乙基三甲基氯化铵)(PAOTAC),对棉纤维进行改性,然后采用浸-轧-蒸工艺进行活性染料染色,一定程度上改善了耐日晒牢度。其主要机制是固色过程中PAOTAC中的酯键在碱性条件下发生水解,织物表面的季铵盐基团及其结合的水解染料等可在后续皂洗过程中被洗除。

由于分子质量较大的阳离子改性剂不易向纤维内部扩散,改性后会导致织物染色不匀、透染性差等问题;纤维表面的阳离子基团以静电力吸附阴离子活性染料,也会导致染色织物耐水洗和耐摩擦色牢度降低。而部分阳离子改性剂对环境有危害,故而开发绿色环保的新型阳离子化改性剂、减少阳离子化改性对染色均匀性和色牢度的影响,是该方向未来的工作重点。

1.1.2 活性染料结构改性

为提高活性染料与棉纤维之间的亲和力,除对棉纤维进行阳离子化改性外,还可从染料着手,设计高亲和力的活性染料,主要包括:降低染料的阴离子性,如降低染料分子磺酸基含量;增加染料的阳离子性,即将阳离子型亲水基团引入染料母体或取代染料中的阴离子型亲水基团。其中,研究最多的是增加染料阳离子性,在不加电解质条件下,阳离子型染料可与棉纤维发生较强的吸附作用。

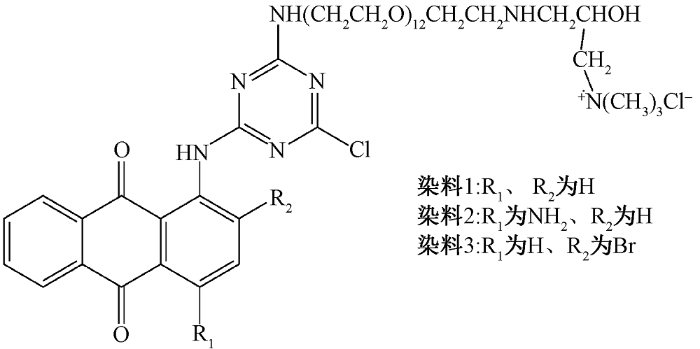

图1

Zhang等[5]合成了一种新型阳离子型染料,分子中具有季铵盐基团,活性基团为烟酸季三嗪。该阳离子型染料可在无盐、无碱条件下对棉纤维染色,上染率达到94.2%,固色率由62.3%提高到72.8%,染色织物的耐水洗、耐摩擦和耐光色牢度与有盐染色的织物相当。

1.1.3 大分子活性染料

活性染料分子结构相对较小,含有的活性基团数量也较少,在水溶液中活性基团会发生水解副反应而失去与纤维发生化学反应的能力,导致活性染料固色率低。

为克服活性基团水解的问题,提高活性染料固色率,大连理工大学张淑芬课题组将多个小分子活性染料引入到多胺(如聚乙烯胺)或多羧酸(如聚马来酸)大分子中,合成了一系列的多胺型[6]或多羧酸型大分子活性染料[7-8]。多胺型大分子染料中保留了部分氨基,可通过其它交联剂在大分子染料和纤维之间建立共价交联,实现牢固结合。而以氰胺类化合物作催化剂,多羧酸型大分子染料中含有的多个羧基,可通过酯化反应与纤维发生共价交联,从而提高固色率,然而由于高温焙烘条件(160~180 ℃下5~15 min)和染色液较强的酸性(pH值为4~5),导致焙烘后染色织物的撕破强力降低10%~20%。由于大分子染料本身对纤维的扩散比较困难,因此通常采用轧烘-轧蒸工艺进行染色和固色,染液中并未加入硫酸钠等无机盐,可实现无盐染色。多胺型或多羧酸型大分子染料的固色率可达到90%以上。对于大分子染料,需要克服其水溶性及对织物的匀染性。

1.2 低给液高固色率染色技术

活性染料染色过程中,大约有20%~50%的染料未能与纤维发生有效反应,随废水排放。为提高活性染料的利用率,研究者们开发了众多低给液染色技术。低给液染色是指染色时织物或纤维的带液率低(20%~40%),很大程度上减少了泳移、无机盐使用量以及染料的水解,从而提高了染料利用率。

1.2.1 泡沫染色技术

1.2.2 真空脱水湿蒸染色技术

为降低固色时织物上的带液率,Zhang等[12]采用真空脱水技术控制织物含水率,并探讨了汽蒸时间、碳酸钠用量等因素的影响。结果表明,将织物含水率真空脱水控制在20%~30%,再进行汽蒸,染料固色率可达到85%以上,染色织物的K/S值比传统轧蒸工艺高,但是真空脱水湿蒸技术染色织物的耐摩擦色牢度比传统轧蒸工艺稍低,真空脱水的均匀性控制也需要重点关注。

1.2.3 喷液染色技术

为均匀地对织物低给液,冒晓东[13]尝试采用压电喷墨打印头喷液技术,开发了低给液喷染技术。研究表明,新型喷染技术可将织物带液率控制在15%~50%,染色织物的染深性、匀染性、色牢度等均与传统轧染织物相当,且固色率有所提高。

1.2.4 “潮固色”染色技术

1.3 少水/非水介质染色技术

使用有机溶剂代替水作为染色介质,可有效减少活性染料染色废水的排放量以及无机盐的使用,提高活性染料的利用率。

1.3.1 乙醇/水混合溶剂染色

乙醇/水体系染色是一种新型的环保和节水的染色技术,织物染色后,可通过分馏工艺对乙醇进行回收利用。

1.3.2 十甲基环五硅氧烷/水混合溶剂染色

1.3.3 食用油/水混合体系染色

1.3.4 液氨染色

1.3.5 有机混合溶剂染色

在少水或非水介质染色方面,尽管取得了很多研究成果,但是由于产业化应用时还需要配套专用设备,溶剂的回收使用也会增加生产成本,溶剂使用对环境的影响还需深入探讨,因此以有机溶剂为介质的活性染料染色技术尚未实现大规模产业化应用。

1.4 针织物平幅连续浸轧染色技术

目前针织物全部采用间歇式浸渍染色技术,生产周期长、布面起毛起皱现象严重。为实现针织物平幅连续浸轧染色,东华大学研究团队协同业内企业对针织物的平幅前处理、防卷边、张力控制、平幅染色工艺和装备进行了系列攻关。为提高平幅染色的得色率和匀染性,文献[29]提出了针织物平幅前处理和丝光相结合的技术;为改善卷边现象,文献[30]开发了具有核壳结构的聚丙烯酸-聚氨酯聚合物防卷边剂,适用于中、厚型单面纬平针织物;文献[31]研究了织物形变对染色性能的影响,证明织物拉伸率在20%以内时,通过在预烘、汽蒸等不同环节施加不同张力,发现对最终织物色深性和匀染性无影响,最终形成了针织物平幅连续染色成套技术,开发了国内外首套针织物平幅轧烘轧蒸连续染色装备,率先实现了针织物连续染色加工技术的产业化。与《印染行业规范条件(2017版)》规定数据相比,该技术可实现节能25%,节水70%,节约无机盐用量65%以上,但是,针织物的平幅连续染色仍然具有局限性,例如卷边程度受到织物规格影响,织物的边中色差和头尾色差也需要进一步改善。

2 分散染料染色新技术

2.1 分散染料碱性染色技术

传统分散染料染色工艺是在酸性条件下进行,因为分散染料和涤纶大分子在酸性条件下更稳定,但是涤纶织物的退浆、碱减量等前处理过程,以及染色完成后的还原清洗、皂洗等过程均是在碱性条件下进行的,故染前和染后均需调节pH值,并消耗一定的化学品和水资源,调节过程中pH值的把控不到位,会导致油剂、浆料、聚酯低聚物、杂质等影响染色质量,出现缸差、染色不匀、色光不纯正等问题[32]。若能实现碱性条件下对涤纶织物染色,则具有提升前处理效果、防止低聚物沾污、免还原清洗、缩短工艺流程、减少酸和水用量等优势。为满足碱性条件下染色,分散染料分子结构中的基团需有较强的耐碱水解稳定性。

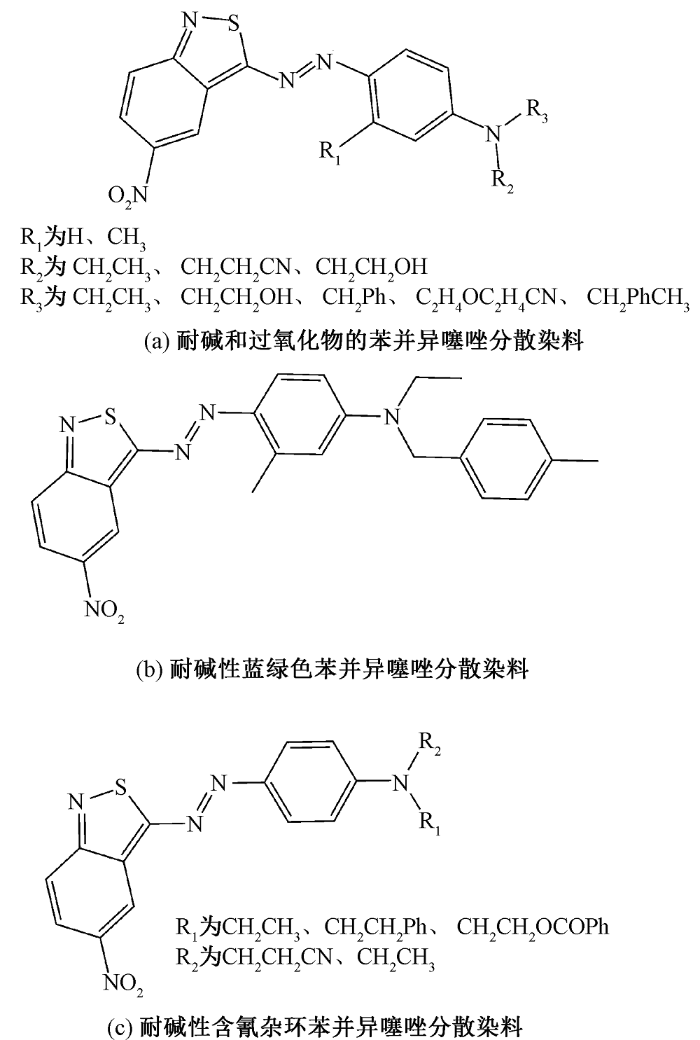

图2

图2

苯并异噻唑类耐碱分散染料的分子结构

Fig.2

Molecular structures of alkali-stable benzisothiazole disperse dyes.

(a)Benzisothiazole disperse dyes with alkali-resistance and hyperoxide-resistance; (b)Blue-green benzisothiazole disperse dyes with alkali-resistance; (c) Cyanogen heterocyclic ring-containing benzisothiazole disperse dyes with alkali-resistance

Aysha等[37]合成了吡唑啉酮/吡咯啉酮类型的耐碱荧光分散染料,这些染料在低、中、高碱性条件下均有一定的荧光特性,且染色后的涤纶织物各项色牢度均较好。

碱性染色技术还可和其它工艺联合,缩短工艺流程,提高生产效率。王小艳等[38]使用高耐碱分散染料对涤纶织物染色,再进行碱减量处理,其染色性能和表面光洁度均较好,还免去了还原清洗的工序;李晓春等[39]采用耐碱性分散藏青(HA)对涤纶织物进行低温退浆和染色一浴加工,发现浆料去除率、强力保留率和色牢度性能均能满足要求。Wang等[34]使用合成的分散染料(见图2(a))分别在NaOH溶液和H2O2/NaOH溶液中对涤纶织物进行染色,发现取代基为乙基、苄基和对甲基苄基时,所合成的分散染料表现出极高的抗碱和抗过氧化物性能,利用该特性,采用碱性还原与染色一浴的方法用于涤纶麂皮织物的生产,以及采用H2O2漂白与染色一浴的方法用于涤纶/棉混纺织物的生产,中试结果表明,新工艺能满足生产要求,在提高生产效率、节能减排方面具有巨大优势。刘淦生等[35]合成的耐碱性蓝绿色分散染料(见图2(b))具有良好的耐碱性和耐氧化性,能够满足涤纶/棉织物碱减量、氧漂一浴法染色的工艺需求,染色后的产品各项色牢度均较好。

2.2 液体纳米分散染料染色技术

由于分散染料在水中的溶解性不佳,需要借助分散剂来维持在水中的分散稳定性。使用传统小分子分散剂(如NNO、MF)易造成染料分散稳定性差和用量大的问题,分散剂在商品分散染料中的含量达到50%~75%。大量分散剂的存在降低了纤维对染料的吸附性,降低了染料的上染率,增加了废水处理成本。

液体分散染料是利用特殊结构的聚合物表面活性剂吸附染料,经物理研磨将染料制成纳米尺度的颗粒分散在水中所得,染料生产过程无需喷雾干燥,具有易储存、染料利用率高等特点,减少粉尘污染和COD排放,成为分散染料制备的发展趋势。如何设计聚合物分散剂的结构,控制和维持溶液中纳米染料颗粒的尺寸稳定性一直是重点关注的问题。

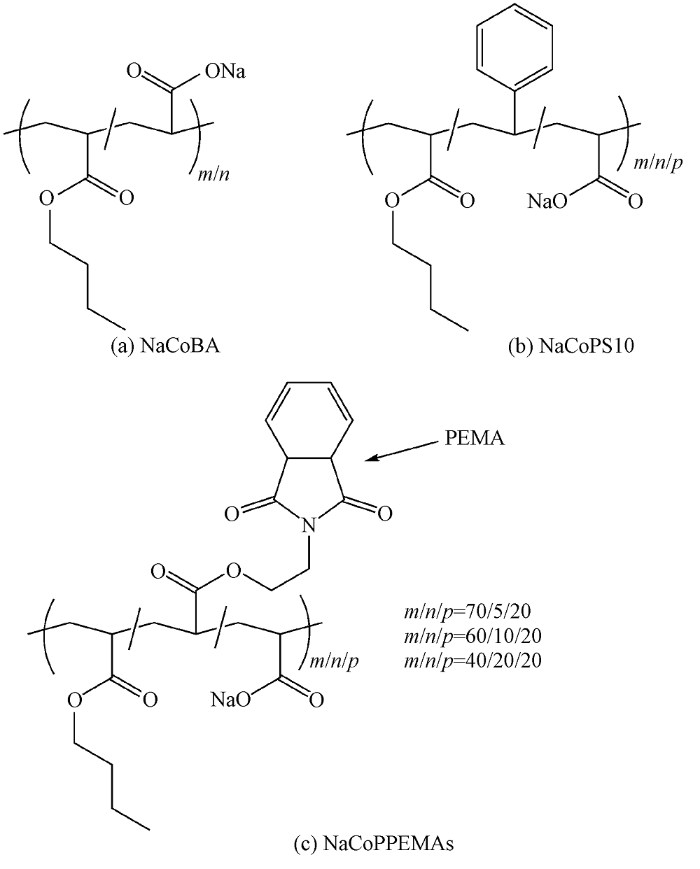

图3

图3

NaCoBA、NaCoPS10和NaCoPPEMAs的分子结构

注:m/n、m/n/p分别表示2种或3种聚合单体的比例。

Fig.3

Molecular structures of NaCoBA, NaCoPS10 and NaCoPPEMAs

随着可持续发展及绿色环保观念的深入普及,分散染料分散剂也朝着生物质方向发展。木质素具有来源广泛、大分子链降解后可功能化改性等优势,众多研究者常利用化学改性方法来获得各种新型的木质素基分散剂。Qin等[44]利用羟丙基磺化木质素分散剂制备了平均粒径为94 nm的纳米分散蓝79,该液体纳米分散染料在高温下表现出优异的分散性和稳定性。Tang等[45]制备了高分子质量聚醚胺桥联木质素磺酸盐,探究了聚醚胺的添加量对染料分散稳定性的影响,使用该分散剂制备的液体纳米分散染料的平均粒径为168 nm,优异的分散性能可以媲美市售Reax 85A分散剂。Chen等[46]以腰果酚为反应物,制备了聚氧乙烯醚类分散剂,并与一种典型的商业表面活性剂(三苯乙烯基聚氧醚)进行比较,结果表明该分散剂具有更好的分散性能和更高的迁移率,其作为一种可生物降解的表面活性剂,可有效代替常规分散染料分散剂,为生物质助剂的制备和应用提供了一种新的策略。

2.3 免水洗连续染色技术

分散染料对涤纶织物染色主要有3种方法:高温高压染色法、载体染色法和热熔染色法,前2种为间歇性染色方法,耗水耗能巨大;热熔染色法作为连续染色技术具有效率高、速度快等特点,但固色完成后,布面残留较多的染料和分散剂,需要进行还原清洗,耗水多,清洗完成后残液中残留的染料和助剂也会加重污水处理的负担,故研究涤纶织物免水洗连续染色技术成为印染工业清洁生产的发展方向。

贾佩[47]利用阴离子分散剂 MF和非离子分散剂壬基酚聚氧乙烯醚复配,制备了平均粒径为300 nm的液体分散染料,配合适当的黏合剂和交联剂等助剂,用于涤纶织物连续染色,取得了较好的染色和免水洗效果。

东莞市金银丰机械实业有限公司与东华大学等联合,从分散染料晶型转变研究、液体梳状分散染料设计及应用、涤纶中厚织物焙蒸免水洗工艺开发等方面进行了大量研究和实践生产,利用开发的液态分散染料和专用焙蒸固色装备,采取浸轧染液→预烘(带液率至10%~20%)→180~190 ℃密闭焙蒸固色工艺,对涤纶织物进行染色,无需水洗,即可获得与常规热熔染色工艺一致的染色效果。

英国AlchemieTechnology公司推出了工业级的连续喷液染色装备,开发专用液态分散染料,实现了涤纶织物低给液染色技术产业化,据该公司宣传资料介绍,与传统染色方法相比,该方法用水量可减少95%,能耗可降低85%。中国台湾的JSRTEX公司引进了一条生产线并已投产。

免水洗连续染色技术除部分敏感色外,所有的颜色都能实现,但从颜色深度上来讲,仅适用于中深色,从织物类型上来讲,较适合于中厚机织物和绒类织物。与传统染色技术相比,免水洗连续染色技术的产品色牢度稍低。

2.4 分散染料非水介质染色技术

2.4.1 超临界CO2流体染色技术

超临界CO2流体(ScCO2)染色技术具有无污水排放、CO2和染料可重复利用、无需干燥过程、染色重现性好等优点。由于弱极性的分散染料在ScCO2中有一定的溶解度,聚酯纤维在ScCO2中有一定的溶胀度,故该技术最先应用于聚酯纤维-分散染料染色体系。近年来,聚酯纤维ScCO2染色技术的研究主要分为以下3类:分散染料在ScCO2中溶解性的测定及相关影响机制研究;聚酯纤维ScCO2染色工艺优化和上染机制研究;聚酯纤维ScCO2染色过程流场分析及染色装备的设计。

分散染料在ScCO2中的溶解度测试方法[50]主要有:静态法、动态法和原位检测法。原位检测法具有可准确判断溶解平衡时间、不会产生相平衡的破坏等优势,故而相对于其它2种间接方法更加准确[51]。由于聚酯纤维ScCO2染色的压力条件较为苛刻,一般大于16 MPa,因此为减少测量工作量和能量消耗,研究者将已测得的不同工况条件下的溶解度数据利用状态方程、半经验方程和神经网络等方法进行建模和预测[52],并阐明了温度、压力、CO2密度等因素对溶解度的影响规律[53]。部分分子质量大、熔点高的分散染料在ScCO2中的溶解度较低,提高分散染料在ScCO2中的溶解性方法有:1)改变染料分子结构[54-55],2)降低染料分子的结晶度[56]和粒径[57],3)利用有机溶剂助溶[58-59],其中有机溶剂助溶效果好且适用范围广,但这些有机溶剂在染色完成后的分离和残留问题难以解决,需要进一步开发适用于ScCO2染色的助溶剂,以拓宽聚酯纤维ScCO2染色技术的染料适用范围。

影响聚酯纤维ScCO2染色效果的主要因素有:温度和压力[60]、流体流量[61]、时间、流场分布等,通过优化这些工艺参数,结合能耗因素,可获得聚酯纤维ScCO2染色的最佳染色工艺[62]。混合染料的上染工艺研究目前也取得了较大进展。有研究者提出了一套适合于聚酯纤维ScCO2染色的三原色配方及其染色工艺条件[63⇓-65],这将有利于ScCO2染色技术的产业化进程。从染色机制方面分析,Kim等[66]利用萃取法对分散染料在聚酯纤维中的扩散行为进行了研究,并进行了染色动力学行为的探究;分散染料在ScCO2和聚酯纤维两相间的分配系数是决定最终纤维得色量的决定性因素[67],黄钢[68]、闫俊[69]、焦安东[70]等均研究了工况条件对分散染料在ScCO2和聚酯纤维两相间的分配系数的影响规律,得出了不同染料的最佳染色工艺,为ScCO2技术的产业化推进提供了理论基础。

2.4.2 有机溶剂染色技术

2)液体石蜡染色技术。An等[82]利用液体石蜡溶解分散红167对涤纶织物进行染色,研究了该体系的染色热力学和动力学,发现液体石蜡浴与水浴的吸附等温线和染色速率曲线具有相同的形状和趋势;但由于分散染料在石蜡浴中的溶解度比在水中的溶解度高,故分散染料在石蜡浴中的染色亲和力较小,扩散活化能较高。

与活性染料染色一样,分散染料在有机溶剂中的染色同样存在溶剂回收、配套染色设备设计等问题,工业化应用还面临着诸多挑战。

3 纺织品结构生色技术

4 结论与展望

活性染料染色技术的发展主要关注于4个方面:首先是提升染料和纤维的亲和力以减少无机盐的使用,但存在匀染性或色牢度不佳的问题;其次是降低纤维带液量,减少染料水解,提高固色率,把握染色的均匀性以及将固色率提高到最高水平是今后研究工作的主要方向;再次是利用有机溶剂或液氨作为染色介质以减少废水排放,溶剂回收和配套设备的开发是这些技术产业化之前需要攻克的难题;最后是利用平幅连续化方式对针织物进行染色,在提高生产效率的同时,兼顾节能降耗,对轻薄织物的适用性和提升生产工艺的稳定性是需要继续努力突破的方向。

分散染料染色技术方面:首先设计耐碱性的分散染料,实现前处理、染色、皂洗联合工艺,解决还原清洗工艺的耗水耗能问题,提高生产效率;其次制备纳米尺度的液体分散染料,提高上染率,减少浮色,配合微胶囊壳层的使用,达到免还原清洗效果,上述2项技术已经基本达到工业化水平,但仍需完善可染织物品类,提高染色质量;最后使用ScCO2流体或有机溶剂等非水介质染色,达到无水染色水平还需要继续完善理论体系和配套设备的开发。

活性和分散染料染色技术不断向绿色降耗方向推进,有利于推动纺织印染行业尽早实现“碳达峰碳中和”目标。

参考文献

Low-salt dyeing of cotton fabric grafted with pH-responsive cationic polymer of polyelectrolyte 2-(N,N-dimethylamino)ethyl meth-acrylate

[J].

Effect of chemical modification with 4-vinylpyridine on dyeing of cotton fabric with reactive dyestuff

[J].DOI:10.1007/s10570-018-2026-6 [本文引用: 1]

Application of a hydrolyzable cationic agent, poly(acryloxyethyl trimethylammonium chloride), in salt-free reactive dyeing for good dyeing properties

[J].DOI:10.1002/app.34023 URL [本文引用: 1]

Synthesis and salt-free dyeing characteristics of cationic reactive dyes containing polyetheramine segments

[J].DOI:10.1111/cote.2016.132.issue-4 URL [本文引用: 2]

Clean dyeing of cotton fiber using a novel nicotinic acid quaternary triazine cationic reactive dye: salt-free, alkali-free, and non-toxic by-product

[J].DOI:10.1007/s10098-014-0821-9 URL [本文引用: 1]

Design, synthesis, and application of amphoteric macromolecular dyes with controllable solubility

[J].

Synthesis and application of poly(vinylamine-co-acrylic acid) macromolecule dyes with high light fastness

[J].

DOI:10.1177/0040517519859936

URL

[本文引用: 1]

New types of poly(vinylamine-co-acrylic acid) macromolecule dyes were designed and synthesized based on poly(vinylamine-co-acrylic acid) and reactive dyes. The structures of the synthesized dyes were characterized by ultraviolet-visible spectroscopy, infrared spectroscopy, proton nuclear magnetic resonance and thin layer chromatography. They were applied for dyeing cotton fibers and high fixations were achieved due to their reactive abilities. The dyed samples showed excellent fastness to washing and rubbing and the light fastness of red, blue and yellow poly(vinylamine-co-acrylic acid) dye could reach grades 3–4, 4 and 6–7, respectively.

Synthesis and properties of poly(styrene-co-maleic acid) macromolecular reactive dyes

[J].DOI:10.1111/cote.v139.1 URL [本文引用: 1]

Review of foam applications on cotton textiles

[J].

DOI:10.1177/00405175221107400

URL

[本文引用: 1]

The wet processing sector in the textile industry consumes a massive amount of water and energy. In addition, the textile industry generates significant amounts of effluents. Consumer awareness, environmental laws and regulations, water scarcity, and high energy costs have forced textile manufacturers to reduce their water and energy usage. An alternative way to minimize water and energy consumption in textile industries is to alter the chemical finishing processes from conventional water‐assisted systems to foam-assisted systems. This review focuses on the prospects of foam application in textile dyeing and finishing. Here, we summarize the foam application methods on cotton textiles from published peer-reviewed sources. We also analyze and compare the results of the dyeing and finishing parameters of the foam application approach over conventional padding methods. Finally, we propose some suggestions for further research on foam technology for textiles.

活性染料泡沫染色技术

[J].

Foam dyeing technology of reactive dyes

[J].

Novel, sustainable and water efficient nano bubble dyeing of cotton fabric

[J].DOI:10.1007/s10570-020-03187-6 [本文引用: 1]

A vacuum-dehydration aided pad-steam process for improving reactive dyeing of cotton fabric

[J].DOI:10.1016/j.jclepro.2017.09.112 URL [本文引用: 1]

棉纱线彩点喷染工艺研究

[J].

Study on spray dyeing process of cotton yarns with color fiber circle

[J].

Combination of wet fixation and drying treatments to improve dye fixation onto spray-dyed cotton fabric

[J].

棉织物的活性染料低含水率焙蒸固色工艺

[J].

Low-moisture content baking and steaming color fixation process for cotton fabrics padded with reactive dyes

[J].

锦纶织物活性染料乙醇/水体系染色

[J].

Nylon fabric with reactive dyes in ethanol/water system

[J].

Study on the salt-free low-alkaline reactive cotton dyeing in high concentration of ethanol in volume

[J].DOI:10.1016/j.jclepro.2019.04.006 URL [本文引用: 1]

Salt-free dyeing of cotton fabric and adsorption of reactive dyes in non-aqueous dyeing system: equilibrium, kinetics, and thermodynamics

[J].DOI:10.1007/s10570-022-04576-9 [本文引用: 1]

Sustainable pilot scale reactive dyeing based on silicone oil for improving dye fixation and reducing discharges

[J].

High sorption of reactive dyes onto cotton controlled by chemical potential gradient for reduction of dyeing effluents

[J].

DOI:S0301-4797(19)30365-2

PMID:30903839

[本文引用: 1]

This research uses soybean oil/water dual-phase solvents system (SWDS) to achieve high dye fixation as well as minimal discharge of waste effluents. Reactive dyeings are one of the most serious pollution sources and few dyeing technologies developed could successfully reduce the generation of toxic substances without decreasing dyeing qualities. Through a remarkable increase in chemical potential of dyes in dyeing medium, SWDS remarkably increased the dye concentration in the internal solvent phase. As a result, % exhaustion of dye was 100%, and % fixation of dye was up to 92% in SWDS. Final discharges of dyes and salts from SWDS were decreased by 85% and 100%, respectively, compared to that from the conventional aqueous system. More than 99.5% of initially added biodegradable soybean oil could be recycled for reactive dyeing without treatments. Furthermore, SWDS could be readily applied in jet-dyeing machines on a pilot scale. Via the reuse of soybean oil, SWDS could save up to $0.26 per kg of fabric compared to aqueous dyeings in terms of materials cost.Copyright © 2019 Elsevier Ltd. All rights reserved.

Cost-effective reactive dyeing using spent cooking oil for minimal discharge of dyes and salts

[J].DOI:10.1016/j.jclepro.2019.04.277 URL [本文引用: 1]

Semistable emulsion system based on spent cooking oil for pilot-scale reactive dyeing with minimal ischarges

[J].

阳离子苎麻纱线在液氨介质中染色性能的研究

[J].

Dyeing property of cationic ramie yarn in liquid ammonia

[J].

Sustainable dyeing of ramie fiber with ternary reactive dye mixtures in liquid ammonia

[J].

DOI:10.1039/d2ra03288k

PMID:35865609

[本文引用: 1]

Liquid ammonia (LA) dyeing is a zero-effluent and sustainable dyeing technology investigated for textiles. In the present work, three bi-functional reactive dyes, Reactive Red 195 (R195), Reactive Yellow 145 (Y145), and Reactive Blue 194 (B194), were used to dye ramie fiber in liquid ammonia, and the dye exhaustion (%) and fixation (%) were compared with ramie fibers dyed with the same dyes in an aqueous dyeing method. Dyeing with a single reactive dye, a binary dye mixture, and a ternary dye mixture in liquid ammonia showed that all the dyes are highly compatible as they showed similar uptake. The total dye exhaustion percentage of dyeing with the ternary dye mixture was 22.6%. After dyeing, a cationic fixing agent (CFA)/decamethylcyclopentasiloxane (D5) micro-emulsion was applied and the dye fixation rate was 96.7% accompanied by high colorfastness to washing (Grade 4-5) and produced uniform shades. Finally, a color triangle of dyed ramie fibers was prepared to exhibit many colorful shades. This work demonstrates the viability of dyeing of textile fibers in liquid ammonia.This journal is © The Royal Society of Chemistry.

棉筒子纱活性染料有机溶剂染色

[J].

Cotton package dyeing with reactive dyes in organic solvents

[J].

Characterization of dimethyl sulfoxide-treated wool and enhancement of reactive wool dyeing in non-aqueous medium

[J].

DOI:10.1177/0040517515591784

URL

[本文引用: 1]

Wool pretreated with dimethyl sulfoxide (DMSO) was characterized and its dyeing behavior in non-aqueous green solvents was investigated. Reactive dyeing of wool in deep shades is challenging because the mandatory alkaline aftertreatment to match the fastness of mordant dyes inevitably causes damage to wool keratin. The current study showed that the colorfastness-integrity dilemma could be solved by replacing water with organic solvents as the dyeing medium. Covalent fixation is predominantly favored in solvent dyeing so that excellent colorfastness is achievable at any given shade without alkali aftertreatment. Compared with aqueous dyeing, solvent dyeing was found to give 30% higher covalent fixation on average, which translated to better colorfastness (0.5–1 grade) at higher color depth (Δ K/ S = 1.3–4.9). In addition, scanning electron microscopy, X-ray diffraction and attenuated total reflection-infrared spectroscopy results indicated that DMSO pretreatment induced morphological and structural changes of wool in favor of dyeability. The findings are crucial to the phasing-out of metal-containing dyes for eco-friendly wool dyeing.

平幅前处理对棉针织物染色性能的影响

[J].

Effect of open width pretreatment on dyeing property of cotton knitted fabrics

[J].

单面纬平针织物平幅轧蒸染色防卷边控制

[J].

De-curling control of single-weft knitted fabric in open width pad-steam dyeing

[J].

平幅轧染中针织物形变对染色的影响

[J].

Influence of knitted deformation on dyeing in flat pad dyeing

[J].

分散染料NaOH介质染色技术

[J].

Alkaline dyeing in NaOH solution with disperse dyes

[J].

Synthesis of benzothiazole-azo disperse dyes for high resistance to alkaline treatments and peroxide bleaching

[J].

Synthesis of benzisothiazole-azo disperse dyes for high resistance to alkaline treatments and peroxide bleaching of polyester and polyester/cotton fabric

[J].

DOI:10.1021/acsomega.2c02720

PMID:36061646

[本文引用: 2]

We proposed in this paper to design and synthesize a series of benzisothiazole-based heterocyclic azo disperse dyes with high resistance to alkali and peroxide. These newly synthesized disperse dyes were confirmed using H nuclear magnetic resonance (H NMR), mass spectroscopy, and a UV-visible spectrophotometer. The resistances to alkali and peroxide were examined by dyeing polyester fabric with these synthesized disperse dyes in sodium hydroxide solution and alkaline hydrogen peroxide solution, respectively. It was found that the disperse dyes having cyano and hydroxyl groups exhibited poor resistance to alkali and peroxide. When the cyano and hydroxyl groups were substituted with ethyl, benzyl, and -methylbenzyl groups, the synthesized disperse dyes exhibited extremely high resistance to alkali and peroxide. Utilizing the high resistance to alkali and peroxide of synthesized disperse dyes, the polyester suede fabric and polyester/cotton blended fabric could be produced by combining pretreatment with dyeing in one bath. From pilot-plant production based on 1-ton fabric, the one-bath process provided the advantages of saving electric power, steam, water, and man-hour.© 2022 The Authors. Published by American Chemical Society.

HAO分散蓝的制备及其染色性能

[J].

Synthesis and dyeing properties of HAO disperse blue

[J].

Alkali resistance mechanism of cyano-containing heterocyclic disperse dyes

[J].

Alkali-stable solid state fluorescent pyrazolo/pyrrolinone disperse dyes: synthesis and application for dyeing polyester fabric

[J].

耐碱分散染料上染涤纶织物免还原清洗工艺

[J].

Reduction cleaning free process of polyester fabrics with alkali-resistant disperse dyes

[J].

涤纶耐碱分散染料一浴低温退浆和染色

[J].

One bath low temperature desizing and dyeing of polyester fabrics with alkali resistant disperse dyes

[J].

Design and prediction of dye dispersibility stabilized by polymeric dispersants using a dye-monomer interaction force measurement

[J].

三苯乙烯基阴离子分散剂在液体分散染料制备中的应用

[J].

Application of tristyrene-based anionic dispersant in preparation of liquid disperse dyes

[J].

The comb-like modified styrene-maleic anhydride copolymer dispersant for disperse dyes

[J].

Study on the dispersion mechanism of the polycarboxylic acid dispersant for disperse dyes

[J].

Preparation and interaction mechanism of nano disperse dye using hydroxypropyl sulfonated lignin

[J].

DOI:S0141-8130(20)30536-5

PMID:32105691

[本文引用: 1]

Particles size of disperse dye in dye bath seriously affected its dyeing quality. Here, we prepared a nano disperse dye with average particles size of 94 nm by self-assembly using a hydroxypropyl sulfonated alkali lignin dispersant (HSAL) and azo disperse dye (C.I. disperse Blue 79). The nano disperse dye exhibited excellent dispersion and stability at high temperature (130 °C), the particle size of that was 1.97 μm. The reducing effect of nano dye (azo structure) was decreased to 5.39% and the dye uptake reached up to 94.27%. The interaction mechanism between lignin derivatives dispersant and dye particles was investigated through the adsorption behaviors by employing quartz crystal microbalance with dissipation monitoring and AFM. The higher adsorption amount of HSAL on the dye surface displayed the more viscoelastic adsorption layer than that of sodium lignosulfonate. High sulfonic group attached to the long alkyl chain in HSAL molecules can stretch out to the aqueous phase to provide a strong electrostatic repulsion to disperse dye particles and form the nano disperse dye self-assembly. The present study provided a novel preparation method of nano disperse dye, that would broaden the efficient and value-able utilization of biomass lignin in dyeing and printing field.Copyright © 2020 Elsevier B.V. All rights reserved.

Preparation of polyether amine-bridged lignosulfonate for utilization as a nano dye dispersant

[J].DOI:10.1016/j.ijbiomac.2022.10.036 URL [本文引用: 1]

Facile synthesis of a cardanol-based levelling agent as a biodegradable alternative to tristyrylphenol ethoxylates for the dyeing of polyester fabric

[J].DOI:10.1111/cote.v138.3 URL [本文引用: 1]

纳米包覆分散染料的制备及其免水洗染色性能

[J].

Preparation of nanoscale capsulated disperse dyes and their washing-free dyeing performance

[J].

纳米分散染料胶囊的制备及其对涤纶织物轧染染色性能

[J].

Preparation of nanoscale disperse dye microcapsules and study of its pad-dyeing properties on polyester fabric

[J].

Measurement and correlation of 1,4-diamino-2-methoxyanthraquinone and 1-amino-2-methoxy-4-hydroxyanthraquinone in super-critical CO2

[J].DOI:10.1080/02533839.2020.1831965 URL [本文引用: 1]

A method for measuring the solubility of disperse red 60 in supercritical carbon dioxide using variable-volume view cell with in-situ UV-Vis spectrometer

[J].

Comparison of four density-based semi-empirical models for the solubility of azo disperse dyes in supercritical carbon dioxide

[J].

A new model and estimation of thermodynamic parameters for the solubility of azobenzene and anthraquinone derivatives in supercritical carbon dioxide

[J].DOI:10.1007/s11696-021-01688-7 [本文引用: 1]

Facile synthesis of 1-butylamino-and 1,4-bis(butylamino)-2-alkyl-9,10-anthraquinone dyes for improved supercritical carbon dioxide dyeing

[J].

Effect of the degree of esterification of disperse dyes on the dyeing properties of polyethylene terephthalate in supercritical carbon dioxide

[J].

分散染料在超临界二氧化碳流体中的溶解性

[J].

Study on solubility of disperse dyes in supercritical carbon dioxide fluid

[J].

Effects of dye particle size and dissolution rate on the overall dye uptake in supercritical dyeing process

[J].DOI:10.1016/j.supflu.2019.05.006 URL [本文引用: 1]

Solubility and data correlation of a reactive disperse dye in a quaternary system of supercritical carbon dioxide with mixed cosolvents

[J].DOI:10.1016/j.jtice.2018.06.028 URL [本文引用: 1]

Effect of the addition of a modifier in the supercritical dyeing of polyester

[J].DOI:10.1111/cte.2010.126.issue-3 URL [本文引用: 1]

An investigation of process parameters on colour during the dyeing of polyester in supercritical carbon dioxide media

[J].DOI:10.1111/cote.v137.6 URL [本文引用: 1]

A dissolution kinetic study of disperse dye in supercritical carbon dioxide to design an efficient supercritical dyeing process

[J].

Supercritical CO2 dyeing for nylon, acrylic, polyester, and casein buttons and their optimum dyeing conditions by design of experiments

[J].

Waterless beam dyeing in supercritical CO2: establishment of a clean and efficient color matching system

[J].

One-step supercritical CO2 color matching of polyester with dye mixtures

[J].

Multicomponent system of trichromatic disperse dye solubility in supercritical carbon dioxide

[J].

Predicting diffusion behavior of disperse dyes in polyester fibers by a method based on extraction

[J].

Dye uptake and partition ratio of disperse dyes between a PET yarn and supercritical carbon dioxide

[J].DOI:10.1016/j.supflu.2005.07.001 URL [本文引用: 1]

Numerical simulation of CO2 and dye separation for supercritical fluid in separator

[J].

A novel jig dyeing apparatus for dyeing polyester with supercritical carbon dioxide and its dyeing effect

[J].DOI:10.1007/s12221-022-3314-1 [本文引用: 1]

Synthesis of novel reactive disperse dyes comprising carbamate and cyanuric chloride groups for dyeing polyamide and cotton fabrics in supercritical carbon dioxide

[J].

Novel synthesis of reactive disperse dyes for dyeing and antibacterial finishing of cotton fabric under ScCO2

[J].

Investigation on the construction, photophysical properties and dyeing mechanism of 1,8-naphthalimide-based fluorescent dyes suitable for dyeing wool fibers in supercritical CO2

[J].

An ecofriendly dyeing of nylon and cotton fabrics in supercritical CO2 with novel tricyanopyrrolidone reactive disperse dye

[J].

High-efficiency dispersant-free polyester dyeing using D5 non-aqueous medium

[J].

Sustainable dyeing of nylon with disperse dyes in decamethylcyclopentasiloxane waterless dyeing system

[J].

Waterless dyeing of polylactic acid with disperse dyes using decamethylcyclopentasiloxane as medium

[J].

Distribution mechanism of disperse dyes with similar substituents in a waterless dyeing system based on molecular dynamic simulation

[J].

Investigation from molecular packing to application of azobenzene disperse dyes on polyester fabrics to realize waterless dyeing

[J].

Dyeing of polyester fabrics based on a liquid paraffin system: thermodynamic, kinetic, and molecular dynamics simulation studies

[J].

Recent advances in environmentally friendly structural colored fabrics

[J].

Efficient preparation of liquid photonic crystals and their application in bionic structural coloration of textiles

[J].

Synthesis of poly(styrene-N-hydroxymethyl acrylamide) microspheres and their application in patterned photonic crystals

[J].

DOI:10.1177/00405175221112661

URL

[本文引用: 1]

In order to achieve bright and durable structural colors, the poly(styrene-N-hydroxymethyl acrylamide) nanospheres with self-crosslinking property were used as structural units to construct patterned photonic crystals. In this article, we thoroughly explore the effect of synthesis factors on particle sizes and monodispersity of poly(styrene-N-hydroxymethyl acrylamide) nanospheres, with the characterization of the performance of prepared poly(styrene-N-hydroxymethyl acrylamide) nanospheres. Then the color effects and durability of structural colors produced from poly(styrene-N-hydroxymethyl acrylamide) photonic crystals were characterized and evaluated. The results showed that the monodisperse poly(styrene-N-hydroxymethyl acrylamide) nanospheres with particle sizes ranging between about 200∼320 nm could be synthesized. The prepared poly(styrene-N-hydroxymethyl acrylamide) nanospheres exhibit typical core-shell structure, in which the hydrophobic polystyrene domain is mainly located on the core, and there is a thin shell mainly rich in hydrophilic Poly(N-hydroxymethyl acrylamide) covering the polystyrene core. Moreover, the poly(styrene-N-hydroxymethyl acrylamide) nanospheres have self-crosslinking properties, which could be confirmed by the thermogravimetric curve. Furthermore, the photonic crystals constructed by prepared poly(styrene-N-hydroxymethyl acrylamide) nanospheres still present vivid and durable structural colors after friction, bending, washing and soaking tests. Specifically, the patterned photonic crystals can be constructed on photo paper, plastic board and fabrics, and the resultant structural colors present significantly iridescent effects. The research results can provide strategic support for the practical application of photonic crystals with structural colors.

Preparation of carbon fiber substrates with structural colors based on photonic crystals

[J].

Structural color fibers directly drawn from colloidal suspensions with controllable optical properties

[J].

Additive mixing and conformal coating of noniridescent structural colors with robust mechanical properties fabricated by atomization deposition

[J].

DOI:10.1021/acsnano.7b08259

PMID:29438609

[本文引用: 1]

Artificial structural colors based on short-range-ordered amorphous photonic structures (APSs) have attracted great scientific and industrial interest in recent years. However, the previously reported methods of self-assembling colloidal nanoparticles lack fine control of the APS coating and fixation on substrates and poorly realize three-dimensional (3D) conformal coatings for objects with irregular or highly curved surfaces. In this paper, atomization deposition of silica colloidal nanoparticles with poly(vinyl alcohol) as the additive is proposed to solve the above problems. By finely controlling the thicknesses of APS coatings, additive mixing of noniridescent structural colors is easily realized. Based on the intrinsic omnidirectional feature of atomization, a one-step 3D homogeneous conformal coating is also readily realized on various irregular or highly curved surfaces, including papers, resins, metal plates, ceramics, and flexible silk fabrics. The vivid coatings on silk fabrics by atomization deposition possess robust mechanical properties, which are confirmed by rubbing and laundering tests, showing great potential in developing an environmentally friendly coloring technique in the textile industry.

仿生光子晶体纤维的研究进展

[J].

DOI:10.6023/A20120556

[本文引用: 1]

光子晶体纤维是由光子晶体结构组成的纤维, 具有高饱和度的结构色彩; 其结合响应性材料或柔性基质可制备各种传感响应性光子晶体纤维, 在可穿戴智能传感设备方面具有应用潜力. 自然界中存在许多光子晶体纤维结构, 比如雪绒花花瓣的绒毛, 撒哈拉沙漠银蚂蚁的毛发, 黑嘴喜鹊羽毛等, 光子晶体纤维的研究对于取代传统纺织业的化学染料具有重要意义. 本综述总结了光子晶体纤维的概念、仿生制备方法、性能及相关应用, 并对光子晶体纤维在纺织业和智能传感领域的应用前景进行展望, 该综述对于发展光子晶体纤维的制备方法及潜在应用具有重要意义.

Research progress of bioinspired photonic crystal fibers

[J].

DOI:10.6023/A20120556

[本文引用: 1]

Photonic crystal (PC) fibers exist in many creatures in nature, which give them bright structural colors. PC fibers refer to fibers with the PC structure, which have a highly saturated structural color. Traditional chemical dyes in the textile industry are difficult to degrade to produce chemical pollution and waste of water resources. PC fibers with structural colors are of great significance for replacing traditional chemical dyes in the textile industry and have great potential in making wearable smart sensing devices. They can be used to prepare various sensor-responsive PC fibers when combined with responsive materials or flexible substrates. This paper reviews the fabrication methods, performance, applications and other related research works of PC fibers. PC fibers are mainly composed of colloidal microspheres. To show the structure and properties of PCs, the colloidal microsphere units are mixed with fiber materials and arranged in an orderly manner, or are directly assembled to fibrous materials. The fabrication methods of PC fibers mainly include template assembly, electrospinning, microfluidic spinning, extrusion assembly, multilayer crimp assembly, iterative size reduction and fabric assembly method. PC fibers have many excellent properties. For example, PC fibers are superhydrophobic after being stacked and arranged, which are similar to feathers of drakes with self-cleaning effect. The inverse opal PC fibers have high porosity, high specific area and periodic structure, which can greatly improve the application performance. PC fibers or fiber stacked fibrous membranes have a bright structural color, which can be used for the fabrication of various responsive PC fibers, such as strain-, humidity-, photothermal-, solvent-, and magnetic-response fiber, which are of great significance to the research and application of wearable smart sensors. Finally, the application prospects of PC fibers in the textile industry and intelligent sensing field are discussed.

纺织品仿生结构生色

[J].

Biomimetic structural coloration of textiles

[J].

DOI:10.1177/004051757204200101

URL

[本文引用: 1]

The thermal dissociations of cellulose N-(2-, 3-, and 4-pyridyl)-carbamates to their respective isocyanates and cellulose were investigated using dynamic and isothermal thermogravimetric analyses. With the aid of a digital computer, kinetic parameters were determined for the dissociation reactions measured by both techniques. First-order kinetics were ob served in every case. Activation energies ranged from 28 to 45 kcal/mole. Entropy of activation values were positive for the 4-isomer and negative for the 2- and 3-isomers. The intermediate postulated for the more thermally labile 4-isomer results from intermolecular catalysis, while those for the 2- and 3-isomers resulted from intramolecular catalvsis.

京公网安备11010502044800号

京公网安备11010502044800号