近年来,随着纳米微球合成技术的发展与进步,以纳米微球为结构基元,通过便捷、零排放及零污染的自组装技术在纺织基材上构建结构生色光子晶体已引起纺织领域越来越广泛的关注[8-9]。然而,纳米微球自组装仿生光子晶体结构生色技术在纺织品着色领域的实际应用,存在2个关键性难题亟待解决。一是纳米微球自组装效率低。在常规的纳米微球自组装过程中,组装基元纳米微球需历经复杂的晶体成核与晶体生长等过程,通常耗时数小时以上,难以实现光子晶体的大面积高效构建。二是光子晶体的结构稳定性与光学性质难以兼顾[10⇓-12]。以常规的聚苯乙烯(PS)微球、聚甲基丙烯酸甲酯(PMMA)微球和氧化硅(SiO2)等硬质微球作为组装基元所构筑的光子晶体在微球-微球之间和微球-纺织基材之间仅依靠范德华力和氢键等弱分子间作用力支撑,在摩擦、弯折、水洗等外力作用下易变形、缺损,甚至整体脱落,导致结构色消减,甚至消失。而提高光子晶体结构稳定性的同时又往往会影响光子晶体的光学性质。针对纳米微球的自组装效率低问题,Li等[12]应用高速离心法制备PS液态光子晶体(LPC),以其作为组装中间体,通过外力剪切诱导组装技术在纺织基材表面快速构建大面积的具有虹彩效应的光子晶体,为仿生结构生色技术在纺织品着色领域的规模化应用提供了一定的理论和实践基础。然而,离心法过程本身比较繁复,且难以控制LPC质量,一次离心易产生硬结晶(局部离心过度),逐级多次离心浓缩则耗时,影响其宏量制备,进而影响光子晶体结构生色技术的规模化应用。目前已报道的策略主要有“点焊”黏结[13-14]、聚合物封装[15-16]、软质微球基元的壳层融合[17⇓-19] 等。上述方法各有利弊,如:“点焊”黏结与聚合物封装2种方法易于实施,但对光子晶体结构稳定性的提升程度有限,且对其光学性质具有负面影响;软质微球的制备繁复,且通常需要特定的设备进行组装加工。

本文提出一种快速制备LPC的方法旋蒸法,并以其为组装中间体,采用外力剪切诱导自组装技术,应用自行研制的中试设备快速连续化制备仿生光子晶体结构生色织物。并通过对纺织基材表面进行特殊高分子预处理,利用界面高分子的弛豫、扩散、再固化性能,稳固光子晶体结构生色层,实现光子晶体的高结构稳定性和高颜色饱和度的一致性。

1 实验部分

1.1 实验材料

苯乙烯(St)、十二烷基硫酸纳(SDS)、过硫酸钾(KPS),分析纯,阿拉丁试剂(上海)有限公司;氮气(纯度为99.99%),杭州金工特种气体有限公司;去离子水(电阻为18 MΩ/cm,实验室自制);纳米炭黑(CB,分析纯)、分散剂-3B、流平剂-L(工业级)、稳固高分子-L浆(工业级)、230 T涤丝纺(海宁绿盾纺织科技有限公司)。

1.2 试样制备方法

1.2.1 PS纳米微球的制备

将 1 000 mL去离子水加入到带有机械搅拌以及冷凝装置的 3 L四口圆底烧瓶中,然后加入 0.8 g SDS、450 g St,以350 r /min 的转速充分搅拌10 min。当水浴温度达到 85 ℃时,将溶解在 50 mL去离子水中的 1 g KPS加入至反应体系内引发聚合反应。反应 4 h后,得到球形度优良的PS纳米微球分散液(固含量为28%~30%)。通过调节乳化剂SDS或引发剂KPS用量制备不同粒径的PS纳米微球。

1.2.2 液态光子晶体的制备

取出 100 mL在1.2.1节所制备的单分散PS纳米微球分散液置于旋蒸瓶中,调节旋蒸瓶高度并进行固定,向其中加入质量分数为 0.2%的分散剂-3B,设置转速为 90 r/min,温度为 45 ℃,旋蒸 40 min后即可得到具有艳丽结构色的液态光子晶体。通过改变旋蒸时间制备不同体积分数的液态光子晶体。

1.2.3 光子晶体结构生色织物的间歇法制备

在织物表面用刮刀涂覆稳固高分子-L浆,80 ℃条件下烘干 3 min,120 ℃焙烘 1 min,使织物表面形成平整的高分子-L膜。使用 20 μm的丝棒将光子晶体组装液(以旋蒸得到的液态光子晶体为100%,添加质量分数为 5%的流平剂,0.02%的炭黑)涂覆于经高分子-L浆预处理的织物表面,并在60 ℃条件下组装5 min,得到光子晶体结构生色织物。

1.2.4 光子晶体结构生色织物的连续化制备

制备流程与1.2.3节所述相同,但在自主研制的中试设备上连续化进行,车速为 1.5 m/min。

1.3 测试与表征

粒径及其单分散性测试:将胶体微球乳液用去离子水稀释1 000倍后,使用Nano-S型激光粒度仪(英国马尔文公司)表征微球的粒径及其单分散性。

Zeta电位测试:将胶体微球乳液用去离子水稀释1 000倍后,使用PALS型液体Zeta电位仪(美国布鲁克海文仪器公司)测试微球Zeta电位值。

表面形貌观察:使用ULTRA55型场发射扫描电子显微镜(德国Carl Zeiss公司)观察微球及光子晶体结构的表面形貌。

光子晶体结构色观察:使用KH-7700型三维视频显微镜(美国科视达公司)及EOS600D型数码相机(日本佳能公司)观察光子晶体及其制备过程中样品的形貌和结构色。

光子晶体反射率测试:使用Maya 2000型光纤光谱仪(美国海洋光学有限公司)表征光子晶体膜的反射光谱曲线。

2 结果与讨论

2.1 PS纳米微球的形貌与粒径及Zeta电位

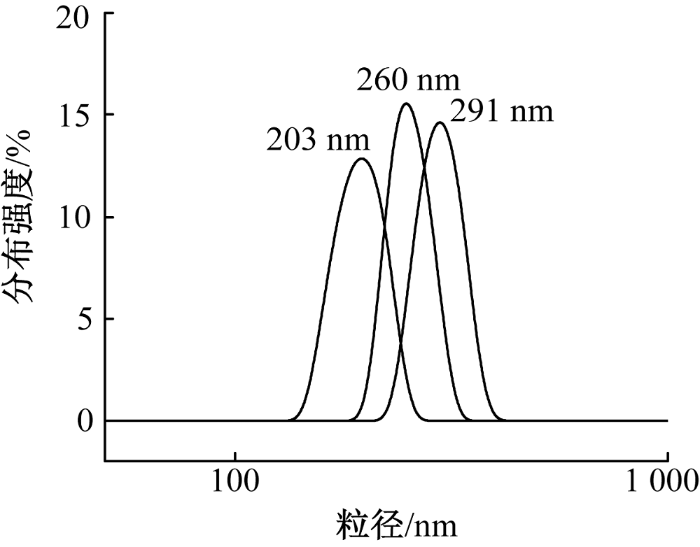

采用乳液聚合法大批量制备尺度均一且粒径可控的PS纳米微球。为实现光子晶体结构生色织物的大面积制备,首先须实现结构基元纳米微球的宏量制备。本课题组前期研究了PS,PMMA,SiO2,P(St-MAA),P(St-BA-MMA),PS/P(BA-MMA)等多种胶体微球的制备和应用,从合成工艺的便捷性、宏量制备的可行性、微球质量(球形度和单分散性)的可调控性、组装效果(结构规整性、颜色鲜艳度)以及价格等多方面综合比较,确定PS纳米微球作为大面积构建光子晶体的第1期首选结构基元。目前,通常单批次制备1.5 L质量分数约为30%的PS纳米微球分散液,制备工艺稳定,并可根据需要等比放大。图1为PS纳米微球的SEM照片。可见,所制备的PS纳米微球尺寸均一,球形度良好。图2示出PS纳米微球的粒径分布曲线。表1示出PS纳米微球的Zeta电位。图2表明所制备的PS纳米微球粒径分布集中,单分散性好;表1中数据则表明体系的Zeta电位在-40 mV附近。值得一提的是:在聚合反应过程中加入的KPS和SDS可使PS纳米微球表面呈现高负电位,保证微球体系的分散稳定性。微球的单分散性、良好球形度、高电位值(绝对值)是后续制备液态/固态光子晶体的必要条件。

图1

图2

表1 PS纳米微球的Zeta电位

Tab.1

| 粒径/nm | 203 | 260 | 291 |

|---|---|---|---|

| Zeta电位/mV | -40.47 | -39.44 | -39.39 |

2.2 液态光子晶体的光学性质

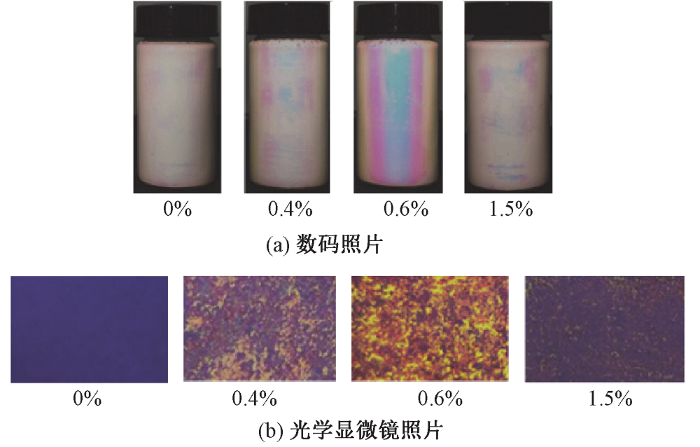

通过物理旋蒸浓缩的方法,提高纳米微球在胶体体系内的体积分数,制备液态光子晶体(LPC)。LPC是以液体(通常为水)为填充介质的非密堆积光子晶体,具有预结晶形态,呈现鲜艳亮丽的结构色,并具有优异的动态可逆回复性。以旋蒸法制备LPC的难点是解决胶体微球的聚沉问题。图3为加入不同质量分数分散剂所制备的液态光子晶体的数码照片及光学照片。由图3(a)可见,当不加入分散剂时,旋蒸后的纳米微球分散液不能展现结构色。这是因为在旋蒸过程中,由于水蒸发,纳米微球间的间距不断缩小,微球间的碰撞概率不断增加,微球凭借合成过程中加入的阴离子表面活性剂SDS所形成的界面阻挡和静电斥力已不足以维持体系的平衡和稳定,因此随着微球浓度的不断提高,微球结晶形成硬质颗粒的现象越来越严重,以致在没有达到形成液态光子晶体的临界体积分数时就已严重聚沉,无法制得LPC。当分散剂的质量分数为0.4%时,旋蒸后的纳米微球分散液局部呈现结构色;当分散剂质量分数增至0.6%时,纳米微球分散液旋蒸后可展现绚丽的结构色;当分散剂质量分数为1.5%时,旋蒸后的纳米微球分散液的结构色表现不明显。这一系列的现象变化是因为在旋蒸过程中引入的特种分散剂-3B(特殊的非离子型表面活性剂)可与体系中已有的SDS阴离子型表面活性剂起到协同作用,显著提高纳米微球之间的空间位阻和电荷效应,使纳米微球表面的三维界面阻挡层成为更坚固的立体屏障。当纳米微球由于体积分数提高而碰撞加剧时,依然具有足够的抵御微球聚沉的能力,使旋蒸体系能按设计要求快速浓缩,制得不同体积分数的液态光子晶体。但当分散剂-3B用量过多时,会干扰微球在水相中的规整排列,从而使结构色变弱。图3(b)中的显微镜照片与上述现象相符合,可进一步说明分散剂-3B在制备液态光子晶体过程中的重要性。

图3

图3

加入不同质量分数分散剂制得的LPC的数码照片及光学显微镜照片

Fig.3

Digital photos (a) and optical microscope photos (b) of LPCs prepared with different mass contents of dispersants

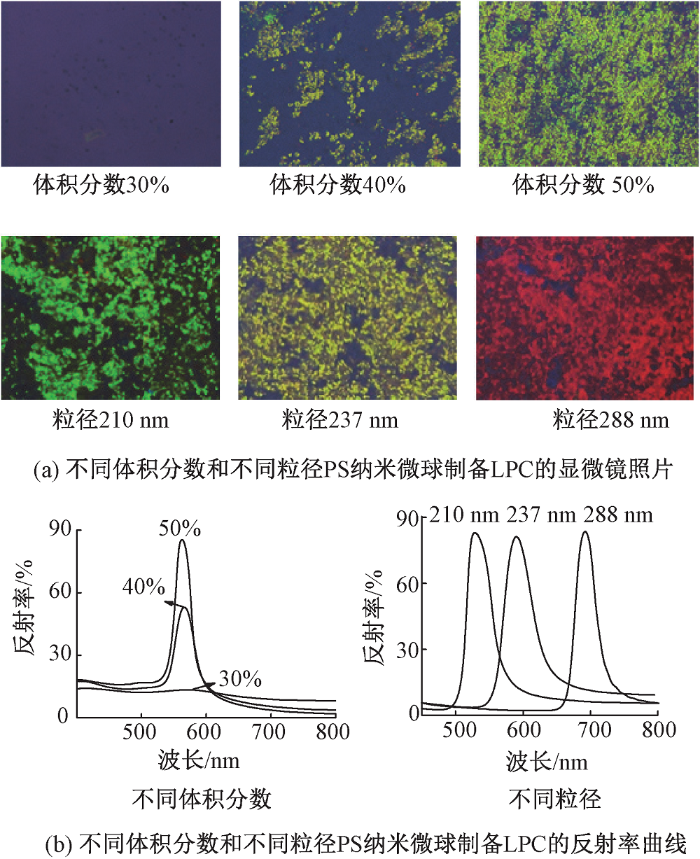

图4示出不同体积分数和不同粒径PS纳米微球制备的LPC的显微镜照片和反射率曲线。如图4(a)所示,随着PS纳米微球体积分数(φPS)的增加,LPC产生的结构色的亮度及饱和度显著提升(图中有颜色区域为结晶区,黑色部分为非晶区)。当φPS为30%时,在显微镜图片中基本不呈现颜色,体系内基本无结晶现象;φPS提升至40%时,可在照片中观察到已有区域性的结构色产生,但结构色的亮度及饱和度均较低,即说明体系内部已有结晶态产生,但结晶程度并不高;当φPS为50%时,LPC产生的结构色区域充斥于显微镜的观察范围内,并且亮度及饱和度更高。相应的反射率曲线如图4(b)所示,随着φPS的增加,反射峰强度愈渐增加,且曲线半峰宽逐渐变小,与显微镜照片所展示的结构色的明亮程度相对应。将LPC的φPS固定为50%,使用不同粒径的PS纳米微球作为构建基元,随着粒径尺度(DPS)增加,LPC的结构色发生明显的红移(见图4(a)),相应的最大反射波长与上述3个颜色也相一致(见图4(b))。这个现象是由于随微球粒径增加,LPC的晶格间距变大,根据布拉格衍射公式可知衍射波长发生红移。结果说明LPC的光学性质可通过纳米微球的φPS以及DPS进行调控。

图4

图4

不同体积分数和不同粒径PS纳米微球制备LPC的显微镜照片及反射率曲线

Fig.4

Microscope images (a) and reflectance curves (b) of LPCs prepared from PS nanospheres with different volume fractions and diameters

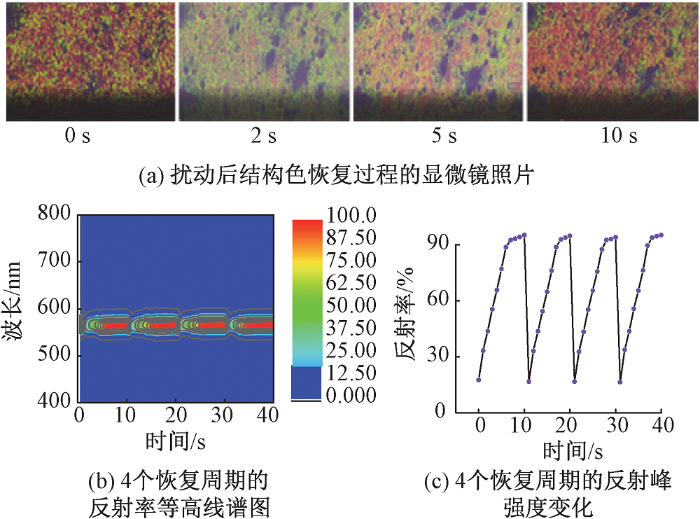

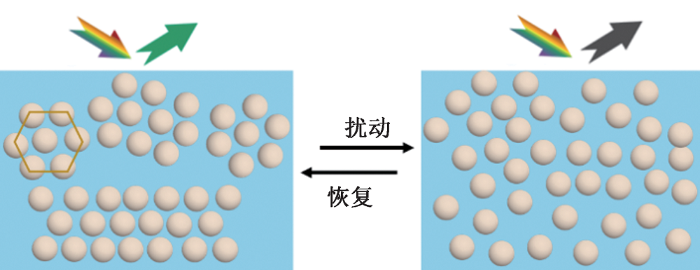

图5

图5

LPC结构色的动态恢复性

Fig.5

Dynamic recovery ability of structural color of LPCs.

(a) Recovery process of structural color after disturbance; (b) Reflectance spectra of four recovery periods; (c)Intensity changes of reflection peaks during four recovery periods

图6

图6

LPC结构动态恢复性示意图

Fig.6

Schematic diagram of dynamic recovery of LPCs structure

2.3 光子晶体结构生色织物制备及结构稳定性

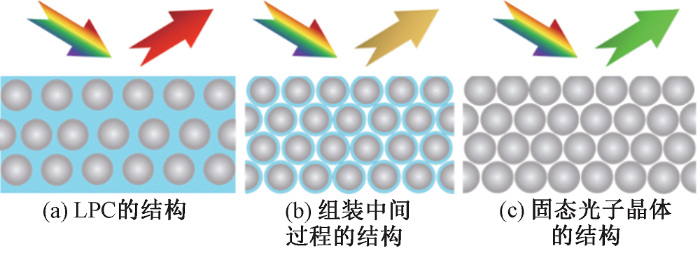

图7

图7

LPC向固态光子晶体转变过程示意图

Fig.7

Schematic diagram of transformation process from LPC to solid photonic crystals.

(a) Structure of LPCs; (b) Structure during self-assembly; (c) Structure of solid photonic crystals

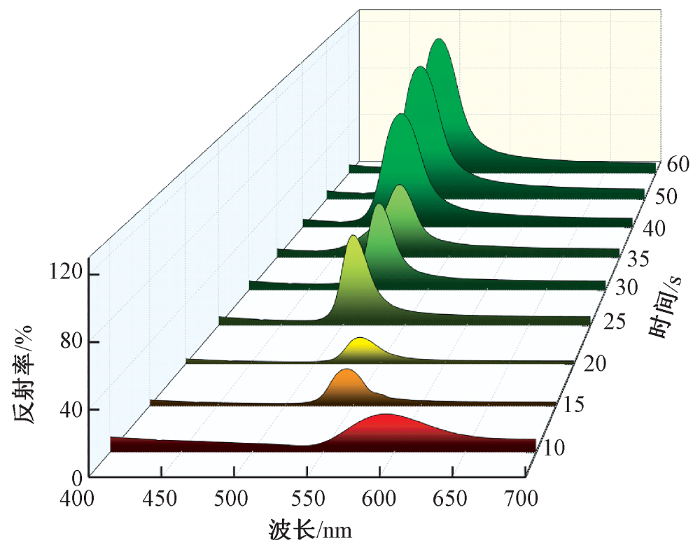

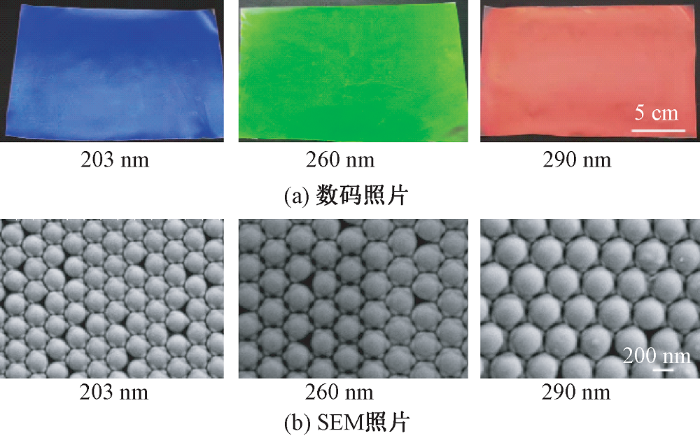

图8为LPC经外力诱导后,在织物表面转变为固态光子晶体过程的动态反射率谱图。可以看出,在0~30 s过程中,反射率较低,这是因为经外力诱导的LPC体系内部晶簇的有序结构被打乱,导致禁带强度降低。待组装时间延长至40 s时,反射峰蓝移至470 nm,且反射率明显增强,这是因为伴随LPC中水分的蒸发,PS纳米微球不断地完善结晶,最终在织物表面形成结构规整的固态光子晶体,此时(60 s)反射率达至最高。正是由于LPC体系内部PS占具较高的体积分数,以致该体系内部水分含量较少,在60 ℃的组装条件下,水分可在短时间内完全蒸发,即在织物表面转变为密堆积形态的固态光子晶体。图9示出由不同粒径PS纳米微球作为组装基元,采用间歇法制备的约为A4尺寸的光子晶体结构生色织物以及相应的SEM图像,其展现的结构色具有高亮度及高饱和度的特性(见图9(a))。由图9(b)可见,纳米微球排列呈规整的密堆积结构,因此可展现绚丽的结构色。

图8

图8

LPC转变为固态光子晶体的动态反射率谱图

Fig.8

Dynamic reflectance spectra of LPCs transformed into solid photonic crystals

图9

图9

光子晶体结构生色织物的数码照片以及相应的SEM照片

Fig.9

Digital photos (a) of structural colored fabric and SEM images (b) of photonic crystals

相对于常规的胶体微球自组装法,应用LPC的外力诱导简化了由单分散胶体微球到胶体晶体的复杂过程,光子晶体的组装可在1 min内快速完成,具有连续化制备大面积光子晶体结构生色织物的工业化前景。

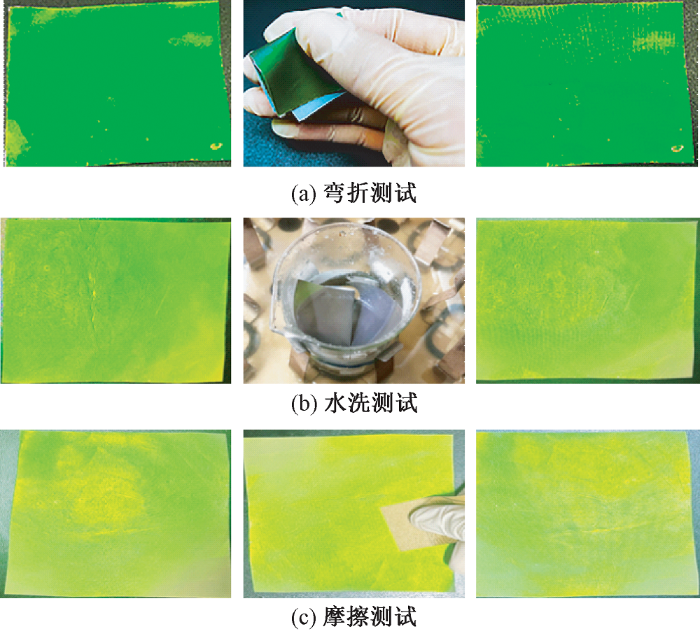

光子晶体的结构稳定性测试结果如图10所示。可以看出,所制备的光子晶体结构生色织物在弯折、水洗、摩擦条件下结构稳定,并无颜色损坏的现象。

图10

图10

结构生色织物的结构稳定性测试

Fig.10

Structural stability test of structural colored fabric.

(a) Bending test; (b) Washing test; (c) Rubbing test

能够实现光子晶体的高结构稳定性和高颜色饱和度的内在原因在于:如图9(b)所示,在纳米微球间有明显的聚合物点状黏结现象,这是由于纳米微球在60 ℃条件下的组装过程中,组装液中的表面活性剂能使织物表面高分子层的界面分子增活,逐步发生蠕变松弛[20],进而在水分子蒸发向上的驱动力以及微球逐步组装形成规整光子晶体结构后产生的毛细管力诱导下,蠕变松弛的高分子链段乃至部分高分子主链向纳米微球间及光子晶体表面迁移。在光子晶体组装完成后,温度降低,这些高分子链段/分子于光子晶体内部二次固化,在光子晶体结构基元纳米微球间起到“韧带”作用,使光子晶体结构“躯干”具有良好的柔韧性。同时,蠕变松弛的界面高分子也能在光子晶体层与织物表面改性高分子层之间起到整体融合连结作用,使光子晶体结构“躯干”站立在坚固的高分子层“大地”上。“韧带”“躯干”“大地”形成一体,显著提高光子晶体结构的稳定性,并可保留光子晶体内部的折光指数差,呈现亮丽的结构色,实现光子晶体结构生色织物的高结构稳定性和高颜色饱和度的一致性[21]。

2.4 光子晶体结构生色织物连续化制备中试

图11

图11

中试设备的数码照片

Fig.11

Digital photos of whole pilot equipment.

(a) Photo of pilot equipment; (b) Photo of fabric outlet of pilot equipment

图12

图12

大面积结构生色织物的数码照片

Fig.12

Digital photo of large-area structural colored fabric

3 结论

1)采用旋转蒸发方式,并结合阴/非离子表面活性剂的协同作用,有效解决胶体微球聚沉难题,快速宏量制备具有预结晶形态的液态光子晶体(LPC)。用旋蒸法制得的LPC呈现鲜艳的结构色,其光学性质可通过纳米微球的体积分数和粒径尺度进行调控。

2)LPC具有优异的动态恢复性。当体系受外力扰动时,液态光子晶体解组装,结构色随之消色;外力释去后,LPC快速重构,预结晶形态恢复,结构色再现(10 s内完成)。表现出快速响应性能和快速组装能力。

3)应用LPC作为组装中间体,结合外力诱导自组装方式及相应的连续化加工设备,可实现光子晶体结构生色织物的快速大面积连续化制备。

4)通过对纺织基材表面进行特殊高分子预处理,利用界面高分子的弛豫、活化、扩散、再固化性能,可稳固光子晶体结构生色层,实现光子晶体结构生色织物的高结构稳定性和高颜色饱和度的一致性。

参考文献

Bio-inspired variable structural color materials

[J].

DOI:10.1039/c2cs15267c

PMID:22302077

[本文引用: 1]

Natural structural color materials, especially those that can undergo reversible changes, are attracting increasing interest in a wide variety of research fields. Inspired by the natural creatures, many elaborately nanostructured photonic materials with variable structural colors were developed. These materials have found important applications in switches, display devices, sensors, and so on. In this critical review, we will provide up-to-date research concerning the natural and bio-inspired photonic materials with variable structural colors. After introducing the variable structural colors in natural creatures, we will focus on the studies of artificial variable structural color photonic materials, including their bio-inspired designs, fabrications and applications. The prospects for the future development of these fantastic variable structural color materials will also be presented. We believe this review will promote the communications among biology, bionics, chemistry, optical physics, and material science (196 references).This journal is © The Royal Society of Chemistry 2012

A robust smart window: reversibly switching from high transparency to angle-independent structural color display.

[J].DOI:10.1002/adma.201500281 URL [本文引用: 1]

Synthesis of highly uniform Cu2O spheres by a two-step approach and their assembly to form photonic crystals with a brilliant color

[J].

DOI:10.1039/c5nr08401f

PMID:26931519

[本文引用: 1]

Monodisperse semiconductor colloidal spheres with a high refractive index hold great potential for building photonic crystals with a strong band gap, but the difficulty in separating the nucleation and growth processes makes it challenging to prepare highly uniform semiconductor colloidal spheres. Herein, real monodisperse Cu2O spheres were prepared via a hot-injection & heating-up two-step method using diethylene glycol as a milder reducing agent. The diameter of the as prepared Cu2O spheres can be tuned from 90 nm to 190 nm precisely. The SEM images reveal that the obtained Cu2O spheres have a narrow size distribution, which permits their self-assembly to form photonic crystals. The effects of precursor concentration and heating rates on the size and morphology of the Cu2O spheres were investigated in detail. The results indicate that the key points of the method include the burst nucleation to form seeds at a high temperature followed by rapid cooling to prevent agglomeration, and appropriate precursor concentration as well as a moderate growth rate during the further growth process. Importantly, photonic crystal films exhibiting a brilliant structural color were fabricated with the obtained monodisperse Cu2O spheres as building blocks, proving the possibility of making photonic crystals with a strong band gap. The developed method was also successfully applied to prepare monodisperse CdS spheres with diameters in the range from 110 nm to 210 nm.

3D Bulk ordering in macroscopic solid opaline films by edge-induced rotational shearing

[J].DOI:10.1002/adma.201003934 URL [本文引用: 1]

Shear-induced organization in flexible polymer opals

[J].

Photophysics of structural color in the morpho butter-flies

[J].

Bio-inspired intelligent structural color materials

[J].

DOI:10.1039/c9mh00101h

[本文引用: 1]

Bioinspired structural color materials represent a curiosity-led, technology-driven field with multidisciplinary research studies aiming at mimicking and recapitulating natural coloration and functions. Over the past several decades, great achievements have been made, including natural structural coloration mechanisms, fabrication of artificial structural color materials, and their applications in extensive areas. In very recent years, research has been propelled forward towards making structural color materials intelligent by incorporating fascinating functions such as self-healing, autonomous regulation, shape memory, etc. These accomplishments create a great leap for structural color materials being applied in real-life scenarios and devices such as in anti-counterfeiting, displays, sensors, soft robots, wearable electronics, organ-on-a-chip platforms, etc.

Precise assembly of highly crystalline colloidal photonic crystals inside the polyester yarns: a spray coating synthesis for breathable and durable fabrics with saturated structural colors

[J].

仿生光子晶体纤维的研究进展

[J].

DOI:10.6023/A20120556

[本文引用: 1]

光子晶体纤维是由光子晶体结构组成的纤维, 具有高饱和度的结构色彩; 其结合响应性材料或柔性基质可制备各种传感响应性光子晶体纤维, 在可穿戴智能传感设备方面具有应用潜力. 自然界中存在许多光子晶体纤维结构, 比如雪绒花花瓣的绒毛, 撒哈拉沙漠银蚂蚁的毛发, 黑嘴喜鹊羽毛等, 光子晶体纤维的研究对于取代传统纺织业的化学染料具有重要意义. 本综述总结了光子晶体纤维的概念、仿生制备方法、性能及相关应用, 并对光子晶体纤维在纺织业和智能传感领域的应用前景进行展望, 该综述对于发展光子晶体纤维的制备方法及潜在应用具有重要意义.

Research process of bioinspired photonic crystals fibers

[J].

DOI:10.6023/A20120556

[本文引用: 1]

Photonic crystal (PC) fibers exist in many creatures in nature, which give them bright structural colors. PC fibers refer to fibers with the PC structure, which have a highly saturated structural color. Traditional chemical dyes in the textile industry are difficult to degrade to produce chemical pollution and waste of water resources. PC fibers with structural colors are of great significance for replacing traditional chemical dyes in the textile industry and have great potential in making wearable smart sensing devices. They can be used to prepare various sensor-responsive PC fibers when combined with responsive materials or flexible substrates. This paper reviews the fabrication methods, performance, applications and other related research works of PC fibers. PC fibers are mainly composed of colloidal microspheres. To show the structure and properties of PCs, the colloidal microsphere units are mixed with fiber materials and arranged in an orderly manner, or are directly assembled to fibrous materials. The fabrication methods of PC fibers mainly include template assembly, electrospinning, microfluidic spinning, extrusion assembly, multilayer crimp assembly, iterative size reduction and fabric assembly method. PC fibers have many excellent properties. For example, PC fibers are superhydrophobic after being stacked and arranged, which are similar to feathers of drakes with self-cleaning effect. The inverse opal PC fibers have high porosity, high specific area and periodic structure, which can greatly improve the application performance. PC fibers or fiber stacked fibrous membranes have a bright structural color, which can be used for the fabrication of various responsive PC fibers, such as strain-, humidity-, photothermal-, solvent-, and magnetic-response fiber, which are of great significance to the research and application of wearable smart sensors. Finally, the application prospects of PC fibers in the textile industry and intelligent sensing field are discussed.

纺织品仿生结构生色

[J].

Biomimetic structural coloration of textile

[J].

DOI:10.1177/004051757204200101

URL

[本文引用: 1]

The thermal dissociations of cellulose N-(2-, 3-, and 4-pyridyl)-carbamates to their respective isocyanates and cellulose were investigated using dynamic and isothermal thermogravimetric analyses. With the aid of a digital computer, kinetic parameters were determined for the dissociation reactions measured by both techniques. First-order kinetics were ob served in every case. Activation energies ranged from 28 to 45 kcal/mole. Entropy of activation values were positive for the 4-isomer and negative for the 2- and 3-isomers. The intermediate postulated for the more thermally labile 4-isomer results from intermolecular catalysis, while those for the 2- and 3-isomers resulted from intramolecular catalvsis.

SiO2溶胶对P(St-MAA)光子晶体生色结构的稳固性增强作用

[J].

Enhancement effect of SiO2 sol on color structure stability of P(St-MAA) photonic crystal

[J].

Shear-induced assembly of liquid colloidal crystals for large-scale structural coloration of textiles

[J].

Study on the fabrication of composite photonic crystals with high structural stability by co-sedimentation self-assembly on fabric substrates

[J].DOI:10.1016/j.apsusc.2018.03.044 URL [本文引用: 1]

Simple fabrication of colloidal crystal structural color films with good mechanical stability and high hydrophobicity

[J].DOI:10.1016/j.dyepig.2015.08.022 URL [本文引用: 1]

Patterned SiO2/PUA inverse opal photonic crystals with high color saturation and tough mechanical strength

[J].DOI:10.1021/acs.langmuir.9b02485 URL [本文引用: 1]

High structural stability of photonic crystals on textile substrates, prepared via a surface-supported curing strategy

[J].

柔性光子晶体结构生色膜的制备及其光学性质

[J].

Preparation and optical properties of flexible photonic crystal film for structural colors

[J].

Reversible deformation of opal elastomers

[J].DOI:10.1021/cm062582a URL [本文引用: 1]

Large-scale ordering of nanoparticles using viscoelastic shear processing

[J].

Mobility gradients yield rubbery surfaces on top of polymer glasses

[J].DOI:10.1038/s41586-021-03733-7 [本文引用: 1]

京公网安备11010502044800号

京公网安备11010502044800号