基于棉和涤纶的非水介质染色技术,本课题组开发了涤纶/棉混纺织物在非水介质染色体系中的基本染色工艺,但存在活性和分散染料相互沾染的现象[13]。在传统水浴染色过程中,为降低染料间的相互串染现象,对涤纶/棉混纺织物进行两浴法染色,但该方法所需时间长、能耗高、废水排放量大。涤棉一浴法染色则存在染料沾染的现象,染色结束后对织物进行皂洗、水洗等方式降低沾色,这不仅会降低生产效率,也会使得后续污水处理难度增大;因此,降低染料在染色过程中的沾色研究十分重要。

为研究分散染料在非水介质染色体系中对涤纶/棉混纺织物中棉组分的沾色机制,基于涤纶/棉混纺织物在非水介质中的基本染色工艺,本文探讨了不同结构分散染料对棉组分的沾色差异,对其在常规水浴与非水介质中的染色性能进行比较,并探讨非水介质染色体系中染色温度、染色时间、促染剂、分散剂及防沾染剂等因素对分散染料沾污染棉组分的影响,为涤纶/棉混纺织物在非水介质染色体系的染料开发提供理论参考。

1 实验部分

1.1 实验材料与仪器

涤纶/棉(65/35)模拟织物(使用1.3 g涤纶和0.7 g棉以模拟2 g涤纶/棉(65/35)混纺织物),100%棉织物 (经纬纱线密度均为15 tex,经、纬密分别为573、128根/(10 cm),面密度为127.2 g/m2),100%涤纶织物(经纬纱线密度均为17 tex,经、纬密分别为175、124根/(10 cm),面密度为112 g/m2),购自苏州凡特思纺织有限公司。

材料:二甲基亚砜(DMSO)、醋酸、碳酸钠(天津科密欧化工试剂有限公司,分析纯),促染剂X(极性小分子,实验室自行研发),十甲基环五硅氧烷(江西蓝星星火有机硅有限公司,工业级),硫酸钠(杭州高晶精细化工有限公司),分散剂NNO(云哲新材料科技有限公司,工业级),皂片(米恩检测仪器有限公司,工业级),偶氮类分散染料 C.I.分散红177、C.I分散橙44(浙江龙盛集团股份有限公司,滤饼),蒽醌类分散染料C.I分散红60、C.I分散紫26,杂环类分散染料C.I分散蓝367(上海贝通色科技有限公司,滤饼)。

仪器:UV-2600紫外分光光度计(岛津企业管理有限公司),Dye-24可调向式染色机(上海千力自动化设备有限公司),SF600X计算机测色配色仪(美国Datacolor公司),FA2004N分析天平(上海菁海仪器有限公司),DHG-9070A电热恒温鼓风干燥箱(上海一恒科学仪器有限公司),J-20脱水机(绍兴鸿靖纺织机械设备有限公司),H1850台式高速离心机(湖南湘仪实验室仪器开发有限公司),FF-101S集热式恒温加热磁力搅拌器(巩义市于华仪器有限责任公司),L-24振荡水浴锅(厦门瑞比精密机械有限公司)。

1.2 实验方法

1.2.1 染色方法

参考涤纶/棉混纺织物在传统水浴中的染色工艺[2],实验选取1.3 g涤纶和0.7 g棉织物作为涤纶/棉模拟织物,水浴中染色配方如下:染色浴比为1:15,分散红177用量为1% (o.w.f),分散剂NNO质量浓度为1.0 g/L,不加入活性染料,硫酸钠质量浓度为100.0 g/L,碳酸钠质量浓度为5.0 g/L,醋酸质量浓度为0.8 g/L,水洗浴比为1:15。

非水介质中染色:在对比传统水浴染色与硅基非水介质染色技术时,分散红177用量为1% (o.w.f),染色浴比为1:15,促染剂X用量为10% (o.w.f),分散染料的染色温度为140 ℃,保温时间为60 min,水洗浴比为1:15;在研究非水介质染色条件对沾色情况影响时,加入1% (o.w.f)分散染料,不加入活性染料,促染剂用量为x% (o.w.f),分散染料染色温度为T (℃),保温时间为W(min),染浴中加入1.3 g涤纶织物和0.7 g棉织物以模拟涤纶/棉混纺织物,工艺曲线如图1所示。

图1

1.2.2 剥色方法

为研究分散染料对涤纶的上染情况和对棉纤维的沾色情况,按照图1所示工艺方法对2 g涤纶/棉模拟混纺织物(1.3 g涤纶织物+0.7 g棉织物)进行染色,染色时只加入分散红177。染色结束后,使用DMSO溶剂进行剥色,浴比为1:100;对棉织物的剥色工艺流程与对涤纶的剥色相同,即室温加入DMSO,以2 ℃/min升温至130 ℃,处理30 min,剥色2次,收集剥色液。

1.2.3 不同结构分散染料在纤维上分布的探究

为比较不同结构的染料对染色性能的影响,初步采用2种偶氮类分散染料(分散橙44、分散红177)、2种蒽醌类分散染料(分散红60、分散紫26)和1种杂环类分散染料(分散蓝367)对涤纶/棉模拟织物、涤纶织物,按照图1所示染色工艺,在染色温度为140 ℃,保温时间为55 min,浴比为1:15的条件下染色。染料用量为1% (o.w.f),染色后测定并计算涤纶和涤纶/棉模拟混纺织物上分散染料的上染率差值,并测试染色织物的表面颜色深度(K/S值),探究非水介质染色体系中,不同结构分散染料对涤纶/棉混纺织物染色性能的影响。

1.2.4 温度对染色性能影响的探究

按照图1所示染色工艺,在促染剂X含量为0%、15%、20% (o.w.f),保温时间为55 min,浴比为1:15的条件下,设置染色温度分别为110、120、130、140、150、160 ℃,探究温度对分散染料染色性能的影响。

1.2.5 促染剂含量对织物染色影响的探究

按照图1所示染色工艺,在染色温度为140 ℃,保温时间为55 min,浴比为1:15的条件下,分别制备含有0%、5%、10%、20%、30%、40%、50% (o.w.f) 促染剂的染色浴并对涤纶/棉混纺织物进行染色,探究促染剂X含量对染料上染率的影响。

1.2.6 保温时间对染色性能影响的探究

按照图1所示染色工艺,在促染剂X含量为15% (o.w.f),染色温度为140 ℃,浴比为1:15的条件下,设置染色保温时间分别为30、40、50、60、70、80 min,探究保温时间对分散染料上染率的影响。

1.2.7 分散剂NNO和促染剂X对染色的影响

按照图1所示染色工艺,在染色温度为140 ℃,保温时间为55 min,浴比为1:15的条件下,分别在含0%、5%、10%、20%(o.w.f)促染剂的染色浴中对涤纶/棉混纺织物进行染色,探究促染剂和分散剂NNO(1%(o.w.f))对涤纶/棉混纺织物染色性能的影响。

1.3 测试方法

1.3.1 染料上染率及沾色率的测定

用紫外分光光度计测量剥色液的吸光度,根据标准曲线计算其染料浓度,进而计算出染料上染率和沾色率。其中:上染率为分散染料上染到涤纶组分的染料占所投入的总染料百分比;沾色率为分散染料沾染到棉组分上的染料占所投入的总染料的百分比。计算公式为

式中:E为染料的上染率或沾色率,%;m为起始染料质量,g;C0为涤纶或棉剥色液的染料质量浓度,g/L;V0为涤纶或棉剥色液的体积,L。

1.3.2 相对沾色率的测定

选取不同结构的分散染料,在工艺条件相同的情况下对涤纶/棉模拟混纺织物和涤纶织物进行染色,测试分散染料的上染率及沾色率。将分散染料在棉纤维上的沾色量与分散染料上染到涤纶上的染料的比值定义为相对沾色率,来表示分散染料对棉组分的沾色程度。

1.3.3 K/S值的测定

使用SF600X分光光度计测试染色织物的K/S值,用以表征染色深度。

2 结果与讨论

2.1 分散染料结构对染色的影响

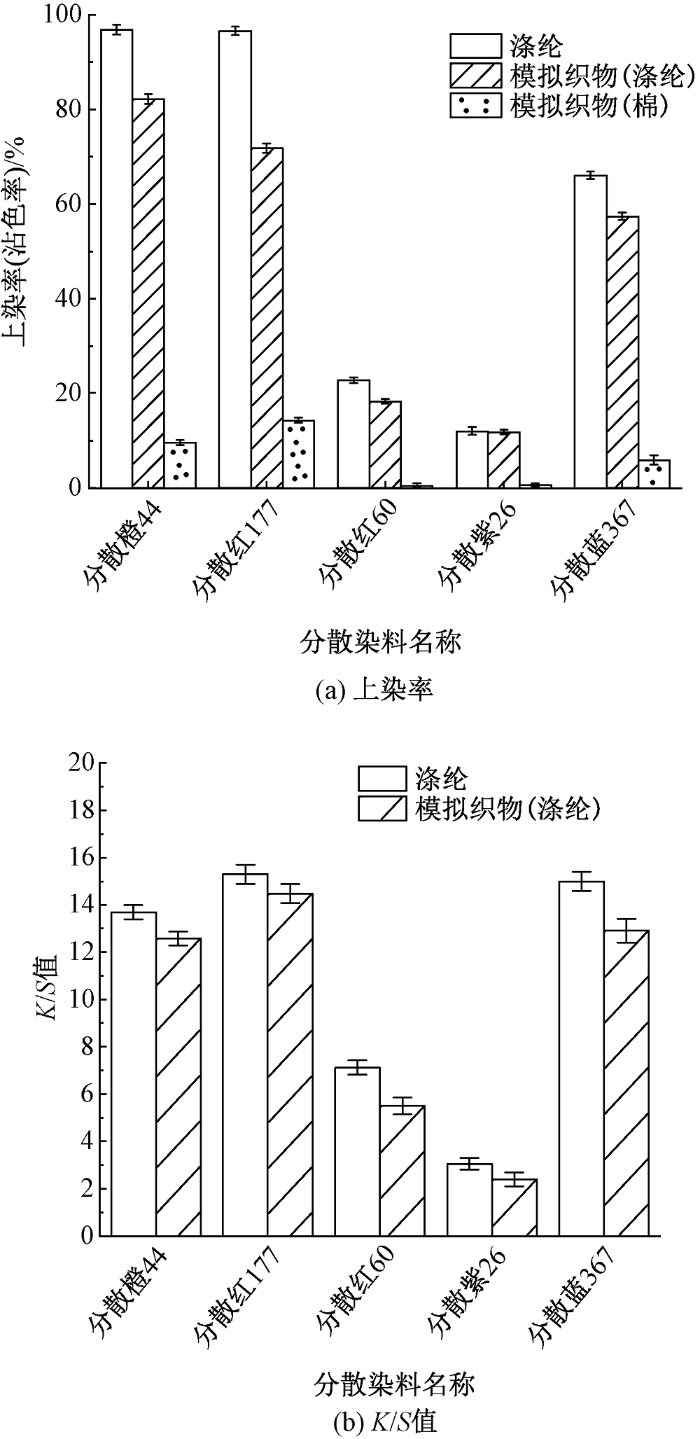

在非水介质染色体系中,不同结构的分散染料染色性能如图2所示。与分散染料染色纯涤纶织物相比,分散染料对涤纶/棉模拟混纺织物中涤纶的上染率和K/S值都较低,如分散橙44对纯涤纶织物的上染率为96.81%,而对涤纶/棉模拟织物中涤纶组分的上染率为82.47%,说明棉纤维的存在影响了分散染料对涤纶的上染。对比不同结构的分散染料,本文所用的偶氮类分散染料对涤纶的上染效果明显优于杂环类和蒽醌类分散染料。蒽醌类分子结构中含有羰基,但分散橙44和分散红177分子结构中含有极性较强的基团,如硝基、氰基以及卤素等,使得分子极性要强于蒽醌类的分散红60和分散紫26。虽然蒽醌类分散染料对棉纤维的沾色率较偶氮和杂环类分散染料低,但其对涤纶的上染率也较低,如实验中选用的分散紫26,其对涤纶的上染率只有12.02%。因此,本文所用的蒽醌类分散染料并不适用于在非水介质染色体系中对涤纶/棉混纺织物的染色。

图2

图2

不同结构的分散染料对织物染色的差异

Fig.2

Differences of fabric dyed with disperse dyes of different structures.

(a) Uptake rate;(b) K/S value

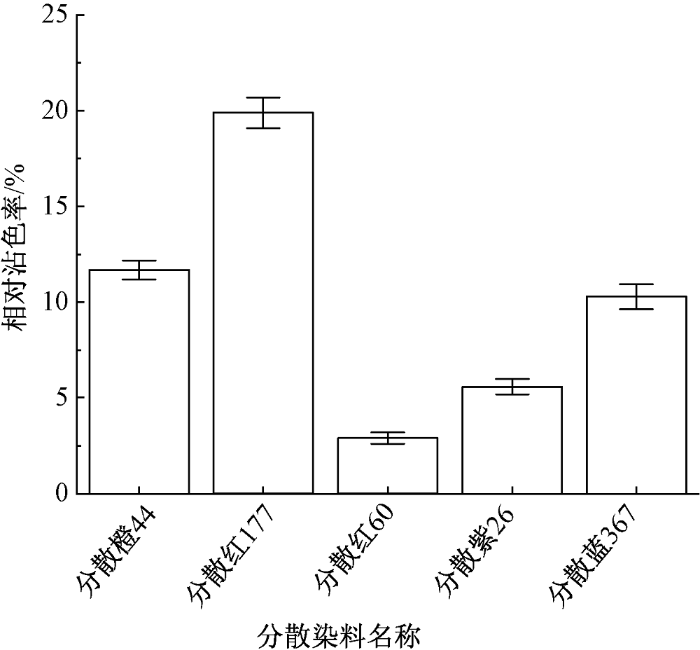

为更直观地分析不同分散染料结构对涤纶/棉混纺织物中棉组分沾色差异,计算了分散染料的相对沾色率,以表示其对棉的沾色程度,结果如图3所示。可以看出,蒽醌类结构分散染料对棉纤维的相对沾色率较低,其中分散红60和分散紫26的相对沾色率分别为2.90%和5.58%。偶氮类分散染料对棉纤维的沾色率较高,如分散红177对棉的相对沾色率为19.89%,说明偶氮类分散染料对棉纤维的沾色程度大。杂环类分散染料分散蓝367相对沾色率为10.28%。

图3

图3

不同分散染料对棉纤维的相对沾色率

Fig.3

Relative staining rates of cotton fibers dyed with different disperse dyes

本文选用的偶氮类分散染料分子结构中含有极性较强的氰基;而D5分子是非极性分子,因此,含氰基的分散染料在D5中的溶解度相对于无氰基的分散染料较低,染色过程中更多的分散染料将分配到纤维固体相,从而提高分散染料对涤纶组分的上染率[13]。但是偶氮类分散染料分子取代基多,与棉纤维上的羟基容易形成氢键;并且偶氮类染料线型较好,与纤维素纤维接触较充分[14-15],因此也更易发生沾色。本文所选用的偶氮类分散染料相较其他类型分散染料具有更高的上染率。不同结构的蒽醌类染料对棉纤维的相对沾色率也不同,与分散红60相比,分散紫26分子结构中增加了苯环结构,因此,染料分子质量增加,分子共平面性强,更容易与棉纤维大分子发生结合,故对棉组分的沾色也较强。

考虑到实际应用中,分散染料在涤纶/棉混纺织物染色中的基本染色原理,分散染料应更多地分配在涤纶上而较少在棉上,对涤纶组分有较高的上染率。本文后续实验以分散红177为例,探究不同染色条件下分散染料在非水介质中对涤纶/棉混纺织物中棉组分沾色情况。

2.2 常规水浴与非水介质染色性能差异

分散红177对涤纶/棉混纺织物染色在水浴与D5中染色性能的差异如表1所示。可以看出,分散红177在D5浴中上染率较水浴提高5.08%;在沾色表现上,水浴中分散红177的沾色率与D5浴较为接近。2种染色工艺染色效果相当,但非水介质染色体系中,染色用水量少,染色过程中不添加分散剂,染色后不需要还原清洗,实现了涤纶/棉混纺织物染色的绿色发展。

表1 分散红177在不同介质中染色性能差异

Tab.1

| 介质 | 上染率/% | 沾色率/% | 染色耗时/min |

|---|---|---|---|

| 水 | 78.42 | 15.03 | 385 |

| D5 | 83.50 | 14.28 | 182 |

2.3 不同含量促染剂下染色温度对染色的影响

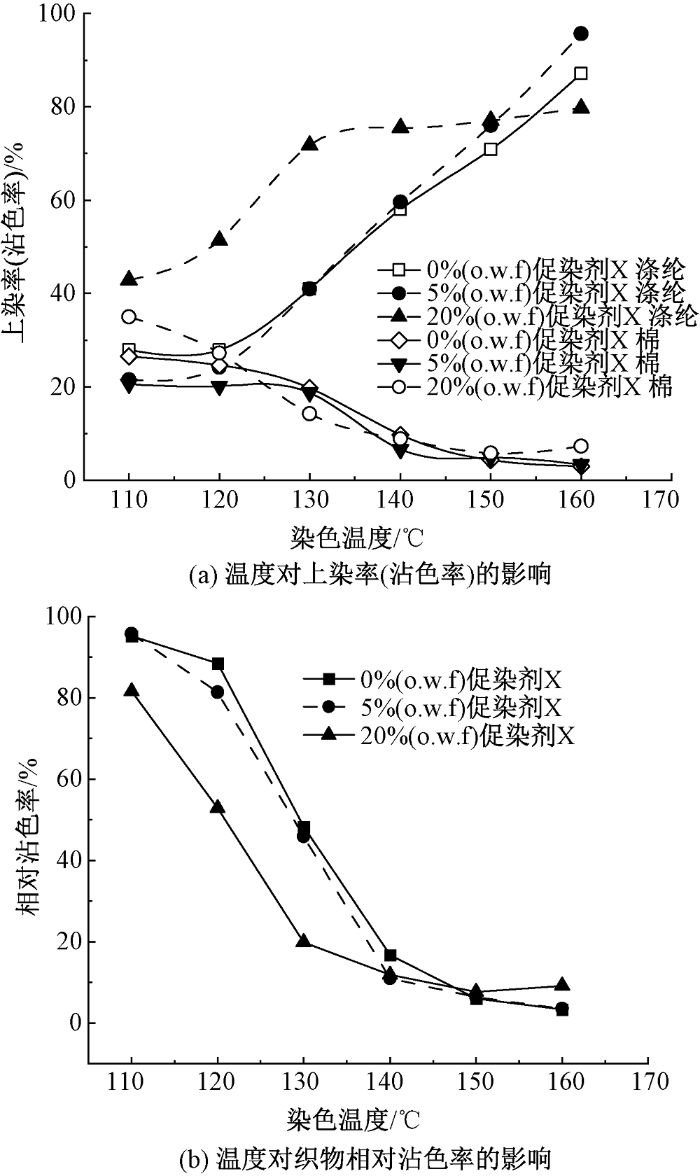

在不同促染剂含量条件下,将分散红177加入到不同温度的染浴中,对涤纶/棉模拟织物进行染色,探究染色温度和促染剂用量对分散染料上染率及对棉组分相对沾色率的影响,结果如图4所示。

图4

图4

不同含量促染剂X染浴中温度对涤纶/棉模拟织物染色性能的影响

Fig.4

Influence of temperature on dyeing performance of polyester/cotton simulated fabrics in dyeing bath with different contents of accelerant X.

(a) Influence of temperature on dyeing uptake/staining rate ;(b)Influence of temperature on dyeing relative staining rate

由图4可知:不同促染剂含量下温度对分散染料沾色率的影响趋势相同,提高温度可以明显改善分散染料对涤纶/棉混纺织物的染色性能;适当加入促染剂可以协同提高分散染料对涤纶组分的上染率,降低对棉组分的相对沾色率。在染色温度低于140 ℃时,促染剂对沾色率降低的作用效果较为明显,当温度高于140 ℃后,不同促染剂用量对相对沾色率的降低效果接近。例如,当染色温度为130 ℃、染色体系中无促染剂时,分散染料的上染率为40.98%,相对沾色率为48.32%;添加20%促染剂时,分散染料的上染率为71.80%,相对沾色率降低至19.89%。当温度超过140 ℃时,促染剂用量增加,相对沾色率增加,例如当染色温度为150 ℃、体系中无促染剂时,相对沾色率为6.03%,添加5%促染剂时,相对沾色率为6.34%,添加20%促染剂时,相对沾色率为7.58%;当染色温度为160 ℃,染色体系中无促染剂时,相对沾色率为3.35%,添加5%促染剂时,相对沾色率为3.55%,添加20%促染剂时,相对沾色率为9.16%。

虽然促染剂的含量不同会导致温度对分散染料上染率的影响不同,但总体趋势相同:分散染料对涤纶的上染率随温度上升而提高,对棉的沾色率也随温度升高而下降,相对沾色率也随温度升高而下降。当促染剂含量为5%(o.w.f),染色温度为110、120、130、140、150、160 ℃时,分散染料对涤纶的上染率为21.50%、24.19%、41.02%、59.63%、75.97%、95.70%;对棉的沾色率为20.64%、20.14%、18.81%、6.60%、4.82%、3.33%;相对沾色率为95.80%、81.36%、45.87%、11.00%、6.34%、3.55%。可见,相同促染剂用量下,染色温度对分散染料的沾色率影响较大。

分散染料对棉组分的沾色分为2种形式:一种是以单分子状态扩散到棉纤维表面或内部;另一种形式是以聚集态形式吸附在棉纤维表面[16-17]。当染色温度高于涤纶的玻璃化转变温度Tg,但低于130 ℃时,虽然非水介质染浴的分散染料多数以聚集态存在,但依然存在单分子染料,在该温度区间,此时涤纶的无定形区内部分子链段开始发生运动,纤维间空隙逐渐打开,但由于温度仍相对较低,单分子染料随染浴运动均匀地分配在涤纶组分和棉组分表面,有少量分散染料进入涤纶纤维内部[18],但染料对涤纶的上染率较低。极性小分子在非水介质染色体系中的作用机制[11,19]是:一方面能够进入涤纶纤维内部,显著改善涤纶的溶胀;另一方面,相对D5非水介质,促染剂的极性较强,减少了分散染料在D5非水介质液体相的分配,从而降低了其在D5非水介质中的溶解度,提高了染料对涤纶的上染率。升高温度,涤纶的分子链段活动剧烈,D5对涤纶的溶胀也提升,高温为染料扩散进入涤纶内部提供能量,染料在非水介质中的溶解度也会提高,但分散染料随介质运动更充分,更多的染料扩散到涤纶纤维内部。由于分散染料只能吸附在棉纤维表面,当吸附饱和时,更多的染料将进入涤纶内部,从而提高其对涤纶的上染率,降低对棉的相对沾色率。

在实际染色过程中,若使用150 ℃或更高的温度进行染色,会增加能源消耗,且对操作人员要求较高,染色作业的危险性较强,故在该体系中染色,建议染色温度为140 ℃。

2.4 促染剂用量对织物染色性能的影响

设置染色温度为140 ℃,将分散红177加入到不同用量促染剂的染浴中,促染剂与染料上染率的关系如图5所示。可以看出:分散染料对涤纶/棉模拟织物中涤纶组分的上染率在促染剂用量低于10% (o.w.f)时,随着促染剂用量增加而提高;促染剂用量高于20% (o.w.f)时,分散染料对涤纶的上染率随着促染剂的增加而降低,直至趋于稳定。分散染料对棉纤维的沾色率随着促染剂用量增加而减少,当促染剂用量为5% (o.w.f)时,分散染料对棉的沾色率只有6.60%,随着促染剂用量增加,分散染料对棉的沾色率逐渐提高。当促染剂用量为10% (o.w.f)时,染料对涤纶上染率达到74.44%,对棉的沾色率为6.87%,此时相对沾色率最低(9.23%)。

图5

图5

140 ℃条件下促染剂X用量对涤纶/棉模拟织物染色性能的影响

Fig.5

Influence of accelerant X amount on dyeing performance of polyester/cotton simulated fabrics at 140 ℃.

(a) Influence of accelerant X amount on dyeing uptake/staining rate;(b) Influence of accelerant X amount on relative staining rate

综上所述,促染剂的添加会同时影响分散染料对涤纶和棉的上染。从前期研究已知,不添加促染剂时D5对涤纶的溶胀能力较差[19],而促染剂X是极性小分子,容易进入纤维内部,能够同时对涤纶和棉产生溶胀,从而提升上染率。对涤纶而言,分散染料向纤维内扩散的阻力减少,但涤纶的溶胀能力有限,因此促染剂添加至一定量后,溶胀达到平衡,染料上染率不再增加。对棉而言,促染剂的增加会提高棉纤维的溶胀,使得分散染料有更多的机会吸附在棉纤维的表面和无定形区。在非水介质染色体系中,分散染料的沾色实际是涤纶与棉竞争染料的过程。涤纶的染色是染料在纤维与染浴中的平衡过程,当染料更多地吸附在棉纤维上时,对涤纶的上染量减少,这也解释了添加促染剂超过20%后分散染料对涤纶的上染率减少的原因。随着促染剂用量增加,棉的溶胀程度增加,而涤纶的溶胀程度则不再增加,故超过促染剂用量10%(o.w.f)后,分散染料的相对沾色率增加。考虑到促染效果和相对沾色率,故选择促染剂用量为10% (o.w.f)。

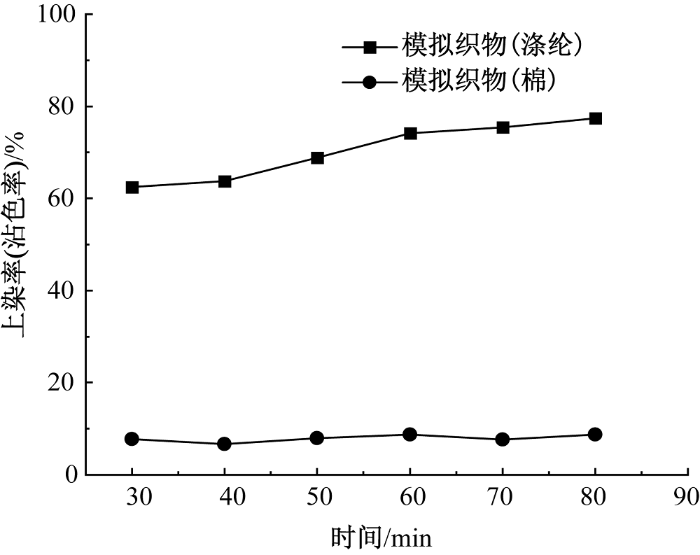

2.5 保温时间对染色的影响

将分散红177加入到染浴中,设置不同的保温时间,保温时间与染料上染率及沾色率的关系如图6所示。可以看出,保温时间对分散染料的沾色几乎无影响,但能提高分散染料的上染率。分散染料能够微溶于D5,溶剂分子与染料分子接触需要一定的时间,此时染色过程也在进行,即溶解于D5中的分散染料不断扩散进入涤纶中,分散染料在D5中的溶解平衡不断被打破,未溶解的染料不断溶解,因此分散染料对涤纶的上染率随着保温时间延长而增加。而分散染料只能依靠范德华力、氢键等弱相互作用力与棉纤维大分子结合。由于D5不能扩散到棉纤维内部,只能吸附在棉纤维表面,因此,分散染料对棉纤维的吸附平衡时间较短。而分散染料对涤纶的上染过程涉及到涤纶分子无定形区,D5能够扩散涤纶纤维内部,改善涤纶的溶胀,但打开涤纶无定形区的孔道需要一定时间,且溶解在D5中的分散染料不断进入涤纶纤维内部。因此,涤纶上染达到平衡需要更长时间。

图6

图6

保温时间对涤、棉双组分上染率及沾色率的影响

Fig.6

Influence of dyeing time on dye uptake rate and staining rate of polyester and cotton

综上所述,非水介质染色体系中,保温时间因素只要考虑使分散染料对涤纶的上染率达到最高即可,无需考虑对棉的影响。考虑染料的利用率及染色效率,认为适合的保温时间为60 min。

2.6 分散剂NNO对沾色的影响

通过改变染浴中染料分子状态的分散稳定性,观察能否减少分散染料对棉纤维的沾色。加入1% (o.w.f)分散剂NNO,在染色温度为140 ℃,保温时间为55 min时,使染料能均匀分布在染浴中,增加染浴中染料分子的分散稳定性,从而降低染料对棉纤维的吸附。不同用量促染剂对染色性能的测试结果如表2所示。

表2 分散剂NNO用量为1%(o.w.f)条件下促染剂用量与分散染料染色性能的关系

Tab.2

| 促染剂用量/ %(o.w.f) | 涤纶上染率/ % | 棉沾色率/ % | 相对沾色率/ % |

|---|---|---|---|

| 0 | 58.49 | 6.51 | 11.13 |

| 5 | 67.13 | 8.16 | 12.16 |

| 10 | 77.70 | 9.41 | 12.11 |

| 20 | 70.48 | 8.16 | 11.58 |

根据2.4节的研究结果,不加分散剂NNO,但染色体系中含有10% (o.w.f)促染剂时,分散染料对涤纶上染率为74.44%,相对沾色率为9.23%。加入分散剂NNO(1%(o.w.f)),分散染料的上染率为77.70%,相对沾色率为12.11%。表明加入分散剂NNO提高了分散染料相对沾色率,也提高了对涤纶的上染率。在促染剂用量为20% (o.w.f)时,分散染料对涤纶的上染率降低。其原因是分散剂 NNO的疏水常数低,对极性物质亲和力强。根据相似相溶原则,强极性的促染剂与水溶性分散剂作用较强,由于促染剂用量的增加,水溶性分散剂、促染剂会引起分散染料在D5中团聚(极性相对D5较强)[20-21],导致分散染料对涤纶上染不匀。且分散剂NNO本身的促染作用是有限的,当分散染料在分散剂的作用下在D5当中的溶解度达到最低时,再继续增加分散剂用量对上染率的提升作用不大[22]。故分散剂NNO不能与促染剂协同降低分散染料对棉纤维的沾色。

3 结论

本文实验通过改变染色条件,分析了分散染料结构、染色温度、促染剂用量、保温时间、分散剂NNO对分散染料在硅基非水介质染色体系中对涤纶/棉混纺织物染色上染率和沾色率的影响,并探究了分散染料对棉纤维沾色的原因,优化了涤纶/棉混纺织物在非水介质体系中的染色工艺,得到如下结论:

1)与蒽醌类和杂环类分散染料相比,含氰基的偶氮类分散染料在非水介质染色体系中具有较高的上染率和沾色率。

2)与常规水浴染色类似,在非水介质染色体系中,温度越高,分散染料对涤纶/棉混纺织物的染色上染率越高,对棉组分的沾色率越低。

3)非水介质染色体系中,染色温度低于140 ℃时,加入适量促染剂可提高分散染料对涤纶的上染率,降低对棉组分的沾色率。

4)非水介质染色体系中,分散染料的最佳染色条件为:温度140 ℃;促染剂用量10% (o.w.f);保温时间60 min。

5)非水介质染色体系中,分散剂NNO不能与促染剂协同降低分散染料对棉组分的沾色。

参考文献

The wash-off of dyeings using interstitial water: part 4: disperse and reactive dyes on polyester/cotton fabric

[J].DOI:10.1016/j.dyepig.2013.06.006 URL [本文引用: 1]

分散/活性染料涤棉混纺织物的一浴一步法染色探讨

[J].

Discussion on one-bath and one-step dyeing of polyester-cotton blended fabrics with disperse/reactive dyes

[J].

One-bath one-dye class dyeing of polyester/cotton blend fabric with disperse dye after esterification of cotton fabric

[J].

Bio-polishing of polyester and polyester/cotton fabric

[J].

DOI:10.1177/0040517505053846

URL

[本文引用: 1]

Enzymatic bio-polishing offers a finish for pill prevention. The present study demonstrates that a cutinase can be used for bio-polishing of polyester fabrics and can be combined with a compatible cellulase to treat polyester and cotton blended fabrics. Two different cutinases were investigated with 100% polyester woven fabric. One cutinase and one cellulase were tested separately and in combination with 50%/50% polyester/cotton blend knit fabric. Following enzymatic treatment, weight loss, high-performance liquid chromatography (HPLC) analysis of the treatment liquor and pilling note were evaluated. An improvement in pilling note for both polyester and polyester blends was demonstrated. Additionally, HPLC analysis of the treatment liquors indicated polyester hydrolysis due to cutinase activity which correlated well with pilling note results

Efficient dyeing mechanism of cotton/polyester blend knitted fabric

[J].DOI:10.1007/s12221-018-8255-3 [本文引用: 1]

The wash-off of dyeings using interstitial water: part 5: residual dyebath and wash-off liquor generated during the application of disperse dyes and reactive dyes to polyester/cotton fabric

[J].

棉织物的活性染料/十甲基环五硅氧烷悬浮体系染色

[J].

Reactive dyeing of cotton in dye/decamethyl cyclo-pentasiloxane suspension system

[J].

A non-aqueous dyeing process of reactive dye on cotton

[J].

Study of hydrolytic kinetics of vinyl sulfone reactive dye in siloxane reverse micro-emulsion

[J].

Thermodynamic characteristics of cotton dyeing with reactive dyes in non-aqueous media

[J].

Dyeing of polyester fabrics based on a liquid paraffin system: thermodynamic, kinetic, and molecular dynamics simulation studies

[J].

Semistable emulsion system based on spent cooking oil for pilot-scale reactive dyeing with minimal discharges

[J].DOI:10.1021/acssuschemeng.9b01003 URL [本文引用: 1]

涤/棉混纺织物在硅基介质中的染色工艺优化

[J].

Optimization of dyeing process for polyester/cotton blended fabrics in silicon-based media

[J].

涤/棉织物分散/活性染料一浴法染色技术

[J].

One-bath dyeing technology of polyester/cotton fabrics with disperse/reactive dyes

[J].

低压无水染色体系中发色母体对分散染料染色性能的影响

[J].

Influence of chromogenic matrices on the dyeing performance of disperse dyes in low pressure anhydrous dyeing system

[J].

Investigation from molecular packing to application of azobenzene disperse dyes on polyester fabrics to realize waterless dyeing

[J].

Mechanism of acelerant on disperse dyeing for PET fiber in the silicone solvent dyeing system

[J].

Sustainable pilot scale disperse dyeing in a waterless silicone medium dyeing system for no discharge of waste-water

[J].

High-efficiency dispersant-free polyester dyeing using D5 non-aqueous medium

[J].

Effect of dispersant on disperse dyeing for polyester fabric in silicone waterless dyeing system

[J].

京公网安备11010502044800号

京公网安备11010502044800号