气凝胶是通过溶胶-凝胶转变以及特种干燥过程而形成的一种纳米级多孔固体材料,具有低密度、高孔隙率、高比表面积等特点,并表现出低热导率、低光折射率、低介电常数、低声速等独特性能[1⇓-3],被评为“2022年度化学领域十大新兴技术”之一[4]。我国在2021年《中共中央 国务院关于完整准确全面贯彻新发展理念做好碳达峰碳中和工作的意见》中明确指出,要大力发展推动气凝胶新型材料的研发与应用。气凝胶自身的超低密度及超低的导热系数使其成为重要的航空航天材料,美国火星探路者探测器,俄罗斯和平号空间站及我国天舟一号货运飞船、天问一号火星探测等航天器,均用到气凝胶作为热防护材料,以应对外太空极热、极寒及冷热交替等挑战[5]。

溶胶-凝胶转变过程在气凝胶制备中占有重要地位。依据凝胶前驱体的不同,溶胶-凝胶转变可分为2种:一种是由前驱体小分子经水解、缩合实现溶胶-凝胶转变;另一种是以纳米材料为构筑单元,直接操纵纳米构筑单元进行溶胶-凝胶组装[6]。纳米构筑单元直接凝胶化组装策略的实施,不仅可直接利用各种低维纳米材料,如碳纳米管、石墨烯、纳米纤维素、量子点等,还可操纵纳米构筑单元进行自下而上组装并将自身特性赋予气凝胶材料,如导电、透明、智能响应等[7-8]。然而,常规溶胶-凝胶转变大都为长时间静置的缓慢反应,难以与现有快速、动态、连续的纺丝、成膜及3D打印工艺进行有机结合,因而气凝胶材料多为宏观块体形态,又因其本征脆性及较差的力学性能,故难以通过后加工方式实现宏观结构形态(纤维、薄膜等)设计与加工。结构形态单一,使得气凝胶在新兴应用领域中竞争力受到影响,因此,目前气凝胶在发展过程中面临的主要科学及技术问题可总结为:1)如何开发新型动态溶胶-凝胶转变原理及策略;2)如何有效调控气凝胶宏观形态;3)如何提高服役性能;4)如何拓展应用领域。

芳纶作为一种高性能战略材料,主要分为对位芳纶(聚对苯二甲酰对苯二胺,即芳纶1414)和间位芳纶(聚间苯二甲酰间苯二胺,即芳纶1313),开发出的产品包括芳纶长纤、芳纶纸、芳纶布等[9]。芳纶具有高强度、高模量、耐高温、耐低温、离火自熄等性能,因此常用于防护领域,如防弹衣、消防衣、装甲车等。目前,芳纶制备采用传统高分子加工方式,具有制备工艺成熟、产品可靠性高等优势,但无法满足现代高分子材料所倡导的高性能化、功能化、多用途性等要求。以芳纶纳米纤维(ANF)作为构筑单元制备气凝胶材料,可最大程度地保留纳米效应、高比表面积等特点,并将低热导率、低介电常数等性能赋予芳纶纳米纤维气凝胶,从而获得高性能化、功能化和多用途的高分子材料。同时芳纶纳米纤维气凝胶的研发将解决目前气凝胶发展过程中面临的主要难点与障碍。本文从芳纶纳米纤维气凝胶的制备机制、宏观形貌调控、结构与性能以及应用等方面进行系统介绍分析。

1 芳纶纳米纤维

1.1 芳纶纳米纤维分散液制备

芳纶纳米纤维分散液的制备方法可分为自上而下法和自下而上法[12]。

自上而下法即由宏观芳纶材料分散成纳米纤维,采用此方法需解决以下问题:1)克服纳米纤维间作用力;2)分散后纳米纤维能保持原芳纶基本性能;3)分散后纳米纤维均匀、稳定,并含有活性基团,便于后续利用。Burch等[13]采用去质子化方法,利用溶液中阴阳离子的电离平衡,使芳纶分子链带负电荷,并在静电作用下分开,从而制备了芳纶纳米纤维,并通过调节释放电荷的多少控制去质子化过程进而控制分散液黏度。然而对于芳纶纳米纤维形态和结构没有进一步探讨。2011年,Yang等[14]采用类似方法,利用二甲亚砜强碱溶液对芳纶进行去质子化,通过吸附酰胺键上的氢,使芳纶纳米纤维在静电斥力和切向力共同作用下彼此分散,制备出直径为5~15 nm、长度为5~10 μm的高长径比芳纶纳米纤维。采用该方法制备的芳纶纳米纤维可通过加入质子供体使纳米纤维之间形成氢键,并形成三维网络结构;然而,去质子化制备芳纶纳米纤维所需时间长(约7 d),制备效率低,于是Yang等[15]在去质子化过程中引入机械研磨、超声波处理以及质子供体(如水、乙醇、甲醇等),以缩短制备时间。因为机械研磨或超声波处理可使芳纶原纤化,其外层皮层被破坏,内部原纤更易被去质子化,质子供体则起到催化剂作用,其更易被夺质子并且生成对应的负离子更易夺取芳纶分子链上的氢。此外,Luo等[16]采用芳纶长纤、短切纤维、芳纶浆粕等为原料制备芳纶纳米纤维。结果表明,以芳纶浆粕为原料制备芳纶纳米纤维所用时长最短。目前,采用自上而下法制备芳纶纳米纤维的效率已获得巨大提升,但该方法以芳纶为原料,生产成本较高。

自下而上法是指由单体或低聚物通过聚合制备芳纶纳米纤维的方法,可有效降低成本。例如,通过低分子质量中间体聚对苯二甲酰对苯二甲酰胺直接合成芳纶纳米纤维[17],该方法成本低且效率高(仅需15 h),但所得芳纶纳米纤维长径比显著低于自上而下法。Yan等[18]直接采用缩聚法制备芳纶纳米纤维,该方法引入甲氧基聚乙二醇作为界面修饰剂和分散剂,所制备的芳纶纳米纤维在水或乙醇等溶剂中表现出优异的分散性,具有高长径比和优异的热稳定性。此外,作为纳米纤维常用的制备方法,静电纺丝[19]也被用于制备芳纶纳米纤维。Yao等[20]在高温(85 ℃)和高压(25 kV)下通过静电纺丝制备芳纶纳米纤维,但所得纳米纤维直径分布宽(275 nm~15 μm), 且芳纶大分子仅溶解于浓硫酸,导致设备腐蚀严重。可见,静电纺丝并不是很好的制备芳纶纳米纤维的方法。

1.2 芳纶纳米纤维分散液流变学行为

为选择合适的加工方法,并预测所得凝胶的形状及气凝胶的结构,需要系统研究芳纶纳米纤维分散液流变学行为,包括黏度、屈服应力、储能模量、损耗模量等。

黏度与分子间内摩擦力有关,受分散液浓度及温度影响,在流变曲线中,黏度是剪切应力与剪切速率的比值,随着剪切速率的增加,黏度会表现出常数或变化的趋势。不同质量分数(0.5%~10%)芳纶纳米纤维分散液的黏度均随剪切速率的增大而减小,表现出显著的剪切变稀行为(流动指数n<1),这表明芳纶纳米纤维分散液在通过狭缝或喷嘴时可有效流动[21]。此外,动态应力扫描测试揭示不同浓度芳纶纳米纤维分散液在 0.1~10 Pa剪切应力范围内均表现出以弹性为主的弹性行为(储能模量G'>损耗模量G″)[21],表明在加工过程中,芳纶纳米纤维分散液类弹性凝胶响应行为可快速恢复,因此,芳纶纳米纤维分散液在通过狭缝或喷嘴后,仍能保持其形状,可进行湿法纺丝、刮刀涂布、3D打印等。

2 芳纶气凝胶纤维

纤维具有纤细、柔长、易编织、易集成等优点,在微型化、集成化、智能化等复杂系统中表现出块体及薄膜材料所不具有的优势。气凝胶纤维是气凝胶结构与纤维形态间的完美结合。研究人员从湿法纺丝、液晶纺丝等纤维制备工艺中汲取灵感,以芳纶纳米纤维分散液为纺丝液,成功制备出一系列不同微观结构、不同性能、不同应用方向的芳纶气凝胶纤维。

2.1 芳纶气凝胶纤维制备

2.1.1 芳纶纳米纤维分散液挤出

对于低浓度芳纶纳米纤维分散液,可采用普通湿法纺丝工艺,利用注射器、微量注射泵、螺杆挤出机等将一定浓度芳纶纳米纤维分散液挤出到凝固浴中。为避免芳纶纳米纤维分散液细流堆叠粘连失去纤维形貌,可通过定速转盘旋转带动凝固浴盘以一定的速度转动,或通过收集辊转动牵伸。

随着芳纶纳米纤维分散液浓度的升高,黏度升高,当到达临界浓度C*时,芳纶纳米纤维分散液开始发生取向,形成液晶态,此时黏度降低。利用液晶态芳纶纳米纤维进行纺丝,即液晶纺,一方面利用液晶态时黏度低易于纺丝特性,另一方面在低拉伸倍率下可获得高纳米构筑单元取向度,二者均有利于获得高强度、高模量的气凝胶纤维[22]。

目前,普通湿法纺或液晶纺均属于低速纺丝技术,生产效率低。如何调控芳纶纳米纤维分散液可纺性,以适应高速纺丝技术,是提升芳纶气凝胶纤维生产效率的关键。

2.1.2 动态溶胶-凝胶转变

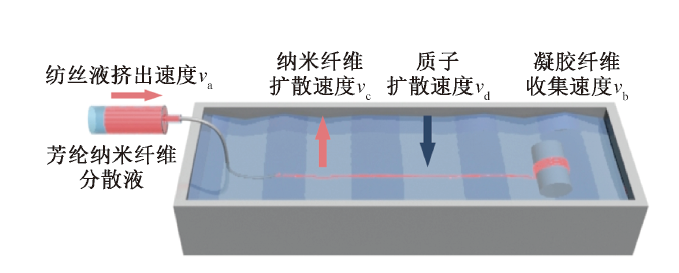

溶胶-凝胶转变是合成气凝胶的必要步骤。如前所述,溶胶-凝胶转变可分为2种,芳纶纳米纤维的溶胶-凝胶过程属于以纳米材料为构筑单元,直接操纵纳米构筑单元进行溶胶-凝胶组装的过程[23]。在凝固浴中提供质子供体时,纳米纤维间重新形成氢键,发生溶胶-凝胶转变。不管是湿法纺丝还是液晶纺丝,其溶胶-凝胶转变均是发生在动态环境中,涉及到纺丝液挤出速度(va)、凝胶纤维收集速度(vb)、纳米纤维扩散速度(vc)及质子扩散速度(vd),当vc<<vd时,芳纶纳米纤维可均匀稳定地发生凝胶转变,本文研究团队将此过程定义为动态溶胶-凝胶转变(见图1)。相比于传统静态溶胶-凝胶转变,此动态溶胶-凝胶转变对纳米构筑单元尺寸有严格限制:分子尺度结构单元太小,扩散速度大于凝胶速度,在进入凝固浴后无法完成溶胶-凝胶过程;微米尺度结构单元太大,进入凝固浴后易形成沉淀而无法获得具有高比表面积的气凝胶纤维;芳纶纳米纤维作为纳米尺度结构单元,进入凝固浴后发生溶胶-凝胶转变,是制备气凝胶纤维的合适构筑单元。

图1

2.1.3 凝胶纤维干燥

将经过动态溶胶-凝胶转变获得的凝胶纤维制备成气凝胶纤维,可采用超临界干燥法和冷冻干燥法2种方法。

超临界干燥法是将芳纶水凝胶纤维置换为醇凝胶纤维或者丙酮凝胶纤维,采用超临界干燥设备将凝胶纤维内部乙醇或丙酮置换为超临界二氧化碳(CO2),降压降温后CO2逸出,即得到芳纶气凝胶纤维。此干燥方法可最大限度地保留凝胶骨架结构。然而,超临界干燥涉及到昂贵、复杂设备,高压操作,能耗高[24]。冷冻干燥法是将芳纶凝胶纤维直接低温冷冻,再转移至冷冻干燥机内抽真空干燥。当采用冷冻干燥法制备芳纶气凝胶纤维时,调整溶剂置换浴的组分与比例,可调控所得气凝胶纤维的微观结构。例如,陈纤等[25]研究了溶剂置换浴中叔丁醇和水的体积比对所得气凝胶纤维微观结构与性能的影响,当叔丁醇和水的体积比为1∶1时,气凝胶纤维具有良好的成形性,其内部纳米纤维排列松散,呈蓬松网状结构,随着溶剂置换浴中水含量的增加,气凝胶纤维的比表面积逐渐下降,力学强度逐渐增加,表明水/叔丁醇体系冷冻过程中溶剂晶体成核生长,导致凝胶网络重排,从而影响纤维内部微观形貌。此外,冷冻干燥法依靠降温设备使溶剂温度降至冰点并结晶,过程能耗高且时间长,因而亟需开发新型干燥方法,如减压干燥、常压干燥等[24]。

2.2 芳纶气凝胶纤维的性能

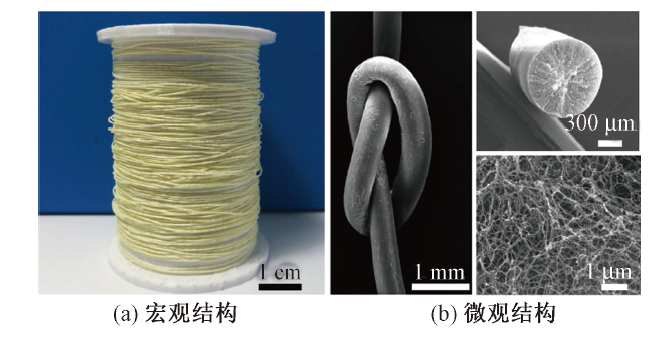

芳纶气凝胶纤维具有纳米级多孔网络结构(见图2),并继承芳纶优异的物理化学性能,表现出超低热导率及优异的力学性能。由于单根气凝胶纤维的热导率目前无法测试,利用COMSOL建模进行理论计算发现,热导率随孔尺寸和纳米纤维直径减小而降低,为0.027~0.032 W/(m·K)[26]。芳纶气凝胶纤维具有如此低热导率主要归因于其孔径尺寸小于空气分子平均自由程(自由空间中空气分子平均自由程约为70 nm),气体分子处于冻结状态,因而有效减少了气体分子的热传导[1]。当芳纶气凝胶纤维进行搭接、组装为织物、絮片等聚集态时,同样具有高效隔热性能,热导率约为0.037 W/(m·K)[22]。在力学性能方面,单根芳纶气凝胶纤维的拉伸强度随纺丝液浓度的增加而升高,采用液晶纺制备的芳纶气凝胶纤维其拉伸强度可达41 MPa[22]。

图2

图2

芳纶气凝胶纤维的结构

Fig. 2

Macroscopic (a) and microscopic (b) morphology of aramid aerogel fibers

2.3 芳纶气凝胶纤维的功能化

芳纶气凝胶纤维可进一步功能化改性,赋予增加其特定功能。芳纶气凝胶纤维具有亲水性,其力学性能随湿度增加而下降,并在湿度达到100%时降至最低[22],需对其进行疏水化改性以保证在长期使用过程中的性能稳定性。目前,疏水化改性有3种途径:一是在芳纶纳米纤维表面涂覆疏水涂层,如氟碳树脂涂层[26],采用这种方法得到的疏水层仅在表面,使用过程中会出现开裂、脱落等问题;二是在芳纶纳米纤维上接枝疏水基团,例如,使用正溴丁烷/乙醇混合溶剂作为凝固浴,烷烃可通过竞争反应接枝到芳纶纳米纤维上,赋予芳纶气凝胶纤维良好的疏水性[27];此外,本文研究团队还将冷等离子体技术应用于芳纶气凝胶纤维的疏水功能化上,采用八甲基环四硅氧烷(D4)作为疏水试剂,其在电场作用下分解形成大量带自由基的小分子,小分子结构易进入纤维内部,在芳纶纳米纤维表面重新组合形成含硅的疏水长链,在纤维内部和表层同样形成疏水层[22]。

2.4 芳纶气凝胶纤维的应用

由于芳纶气凝胶纤维具有传统气凝胶材料及传统纤维材料所不具备的诸多优势,同时具有高比表面积、低热导率和良好的力学强度,在纺织保暖领域具有广阔的应用前景。目前,高端保暖絮片或织物采用的纤维为超细纤维或中空纤维,芳纶气凝胶纤维热导率低于上述2种纤维,利用芳纶气凝胶纤维加工成的絮片或织物具有优异的隔热性能;同时,气凝胶纤维间微米/毫米级大孔提供透气性,满足保暖领域对透气性的要求(见图3(a))。进一步,为获得更加舒适的穿着体验,芳纶气凝胶纤维需具有触感舒适性和/或温度管理功能,其中触感舒适性与纤维柔韧性有关,而柔韧性是弯曲刚度的倒数,可通过控制纤维直径来调节;为获得温度管理功能,利用芳纶气凝胶纤维强毛细作用负载相变材料,可获得具有温度管理功能的气凝胶相变纤维(见图3(b)), 此纤维相变焓值可达172 J/g,远高于商用相变调温纤维(相变焓约为4 J/g)[27]。

图3

图3

芳纶气凝胶纤维织物与芳纶气凝胶相变纤维智能调温织物

Fig. 3

Aramid aerogel fabric and aramid aerogel confined phase change fiber and its fabric.

(a) Optical photo of aramid aerogel fabric and its optical micrographs; (b) Thermal management performance of aramid aerogel confined phase change fiber and optical photo of its fabrics

芳纶气凝胶纤维在吸附领域也具有应用前景,其在吸附方面已有众多研究进展,例如,Meng等[29]研制出的二氧化硅气凝胶纤维表现出比活性碳纤维更优异的吸附性能。在一定染料废水浓度下,二氧化硅气凝胶纤维在2 min及5 min内对染料去除率分别达91.6%和98.2%;而活性碳纤维毡同一时段内对染料去除率仅为57.3%和71.3%。在废水净化模拟实验中,二氧化硅气凝胶纤维可以在常压下迅速将蓝色染料废水处理成无色透明的净水。芳纶气凝胶纤维同样具有高比表面积、高孔隙率、大孔容(可达4.0 cm3/g)等特点[27],复杂多级孔结构使其具有优异的吸附能力,可广泛应用于吸附领域,且通过调节气凝胶纤维的堆积密度,可控制吸附速度。此外,芳纶气凝胶纤维功能化后,将获得选择性吸附材料,如在芳纶纳米纤维表面化学修饰上聚酰胺肟,制得可选择性吸附铀的气凝胶纤维,对铀的最大吸附量可达262.5 mg/g[28]。

3 芳纶气凝胶薄膜

3.1 芳纶气凝胶薄膜制备

芳纶纳米纤维分散液的黏度随剪切速率的增大而减小,具有剪切变稀特性,为塑性流体,因此可利用刮刀涂布或旋转涂布进行制膜。刮刀涂布时,通过调整刮刀与基底间距离可控制成膜的厚度;旋转涂布时,通过调整转速、时间控制成膜厚度。此外,真空辅助抽滤法也是获得芳纶纳米纤维膜的常用方法[30]。目前,芳纶纳米纤维分散液尚未实现大尺寸、连续化成膜。建议借鉴工业薄膜制备技术,如挤出流延法、挤出吹塑法等实现芳纶纳米纤维分散液的大尺寸、连续化成膜。

芳纶纳米纤维膜转移至凝固浴(提供质子试剂,如水、乙醇、酸等)中,凝固浴中的质子通过扩散进入溶胶薄膜内,同时芳纶纳米纤维向外扩散,若质子扩散速度大于纳米纤维扩散速度,芳纶纳米纤维即可发生质子化,同时氢键、π-π等相互作用使其发生凝胶转变,此过程与湿法/液晶纺丝过程伴随的动态溶胶-凝胶转变相似,亦为动态溶胶-凝胶转变过程。

芳纶凝胶薄膜的干燥方法与凝胶纤维的干燥方法一致,主要为超临界干燥法或冷冻干燥法。超临界干燥法:首先将芳纶凝胶薄膜用乙醇或者丙酮置换,再采用超临界干燥设备将凝胶薄膜内部乙醇或丙酮置换为超临界CO2,降压降温后即得到芳纶气凝胶薄膜。冷冻干燥法:将芳纶凝胶薄膜用水或者水/叔丁醇混合溶液置换,随后转移至冷冻干燥机内,在抽真空过程中水或者水/叔丁醇混合溶液先沸腾后结冰(抽真空过程气压下降造成水或水/叔丁醇的蒸发速度加快,直至沸腾,同时气化过程吸收大量热量,使得容器温度快速下降,当降至水或水/叔丁醇的凝固点以下时结冰),然后在真空条件下使固态水或水/叔丁醇直接升华,完成凝胶薄膜的干燥。相比于采用水体系,水/叔丁醇混合体系的冰晶尺寸更小,更加完整地保留骨架三维网络结构,是目前冷冻干燥法首选的溶胶置换体系[31]。如2.1.3节所述,超临界干燥法或冷冻干燥法均存在诸多问题,亟需开发更加节能、环保的干燥方法。

3.2 芳纶气凝胶薄膜的性能

芳纶气凝胶薄膜同样为三维网络多孔结构,其扫描电镜照片如图4(a)所示,具有超低密度,当分散液质量分数为0.5%时,气凝胶的密度仅为13.03 kg/m3。同时,芳纶气凝胶薄膜具有高比表面积,采用超临界干燥获得的芳纶气凝胶薄膜比表面积高达 365 m2/g(见图4(b)。典型的气凝胶结构赋予芳纶气凝胶薄膜优异的隔热性能,室温下热导率为0.036 W/(m·K),该值与纤维素气凝胶及其它隔热材料相当[32-33]。通过测量热源与芳纶气凝胶薄膜表面之间的温差发现,芳纶气凝胶薄膜的隔热性能优于仿北极熊毛织物[31⇓⇓-34]。芳纶气凝胶薄膜继承了芳纶耐高低温的优点,热分解温度为495 ℃,300 ℃条件下仍能维持力学性能。液氮或400 ℃处理后,芳纶气凝胶薄膜的拉伸强度依然保持60%以上,说明该薄膜能够承受极端环境。

图4

图4

芳纶气凝胶薄膜微观形貌与氮气吸脱附曲线

Fig. 4

SEM image(a) and nitrogen adsorption-desorption isotherm(b) of aramid aerogel film

力学性能在实际应用中非常重要,尤其是对柔性自支撑薄膜来说。本文研究团队测得采用芳纶纳米纤维分散液质量分数为2%制备的气凝胶薄膜拉伸强度为1.27 MPa,应变为12.9%[31],超过相同分散液浓度制备的纤维素气凝胶以及其它由纳米纤维制成的气凝胶[7,32]。致密化处理有助于提升气凝胶多孔材料的强度和韧性,适当程度的致密化处理仅会消除大孔,不会破坏气凝胶结构的介孔和微孔。对上述芳纶气凝胶薄膜进行致密化处理(10 MPa压力),拉伸强度达到8.6 MPa,弹性模量达到 178 MPa[35]。 Yang等[30]将自下而上合成的芳纶纳米纤维通过真空辅助过滤和冷冻干燥技术制备出气凝胶膜(PANF),再将低温溶液缩聚制备的杂环芳纶(HA)涂覆在芳纶气凝胶膜上,干燥后获得HA/PANF气凝胶薄膜。HA形成的致密表面涂层具有优异的力学性能,渗透的 HA与PANF网络互穿形成界面互锁结构,将拉伸强度进一步提高到11.4 MPa, 模量提高到624 MPa[30]。

3.3 芳纶气凝胶薄膜的应用

芳纶气凝胶薄膜具有的多孔结构特征以及优异的力学、电学(与导电纳米材料复合后)、热学性能,使其具有广阔应用前景,如分离过滤、电磁屏蔽、红外隐身、热管理等。

芳纶气凝胶薄膜由互连的纳米纤维组成,具有高孔隙率和超亲水/水下超疏油特性,能高效进行水包油乳液分离(分离效率达98.1%),渗透率高达 1 940 L/(m2·h), 循环10次后仍保持98.0%以上的高分离效率,因此,芳纶气凝胶薄膜在乳液分离领域具有广阔的应用前景[38]。

碳纳米管/芳纶气凝胶膜及其炭化后气凝胶薄膜具有三维多孔网络结构和高导电性能,适合作为电磁屏蔽材料。随着气凝胶薄膜电导率的升高,电磁屏蔽效率也随之提高,对于电导率为8 540 S/m、厚度为101 μm的气凝胶薄膜,电磁屏蔽效率高达54 dB(99.999%的电磁波被屏蔽)。碳纳米管/芳纶气凝胶膜及其炭化后气凝胶薄膜表现出的优异屏蔽性能主要归因于入射电磁波与导电多孔网络的相互作用[39],多孔结构又增加了波的多重散射路径,使得材料对电磁波的衰减能力进一步增强。这种高导电芳纶气凝胶薄膜除具有电磁屏蔽性能外,也赋予了其优异的焦耳加热性能,通过施加不同电压可实现温度调控,而且驱动电压较低,在电子设备电磁屏蔽和温度管理领域具有应用价值。

芳纶气凝胶薄膜具有低密度、低热导率以及良好柔韧性等特点,可应用于不规则物体的隔热保温。此外,芳纶气凝胶薄膜具有高孔隙率、强毛细作用,可作为多孔骨架限域其它功能材料。本文研究团队以芳纶气凝胶薄膜为多孔骨架限域相变材料聚乙二醇并进行疏水化处理,获得气凝胶/相变复合薄膜,该薄膜相变焓高、红外发射率与多数背景环境匹配、3~15 μm 红外波段透射率低,可应用于红外隐身领域。在室外环境下,得益于芳纶气凝胶/相变复合薄膜高相变焓值和大比热容,减缓目标物体升温/降温速率,始终与背景环境温度一致,实现自适应红外隐身。对持续发热的目标物体,采用气凝胶隔热层与气凝胶/相变复合薄膜叠加的组合结构,芳纶气凝胶薄膜隔热性能优异,其相变复合薄膜红外透射率低,因而覆盖这种组合结构的高温目标在红外相机中也能与背景融合,实现自适应红外隐身[31]。

高焓值芳纶气凝胶相变复合薄膜还可应用于芯片热管理。本文研究团队以芳纶纳米纤维为基本构筑单元,经刮刀涂布、溶胶-凝胶转变、多巴胺原位聚合、冷冻干燥等过程得到阻燃性能优异的聚多巴胺/芳纶(PANF)气凝胶薄膜;以其为多孔主体负载低共熔相变(DES)客体,制备出具有阻燃和高效热管理功能的PANF-DES主客体相变薄膜,其相变焓高达225 J/g。模拟芯片工作环境,验证了PANF-DES主客体薄膜的热管理性能:1)通过熔融/结晶过程吸收/释放大量热能,减缓芯片升温/降温速率;2)在循环升降温过程中,PANF-DES主客体薄膜可削减温度波动,维持芯片温度相对稳定[40]。

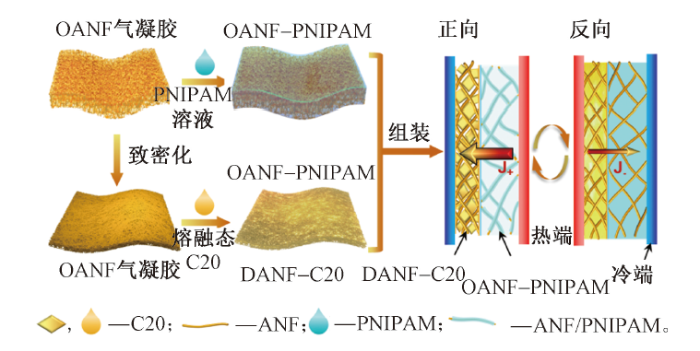

除利用芳纶气凝胶相变材料高焓值进行热管理[40]外,本文研究团队进一步利用2种芳纶气凝胶相变薄膜构筑热二极管,实现热整流。为提升芳纶气凝胶薄膜(OANF) 的力学强度和柔性,对其进行致密化处理得到高强度芳纶气凝胶薄膜(DANF)。筛选出相变温度接近,热导率随温度变化趋势相反、表面润湿性能相反的2种相变材料聚(N-异丙基丙烯酰胺)(PNIPAM)溶液和二十烷(C20),进而制备出芳纶气凝胶相变薄膜OANF-PNIPAM和DANF-C20。芳纶气凝胶薄膜具有极低热导率,不影响相变材料的热导率随温度变化趋势,因此,优化这2种气凝胶限域相变材料的厚度并通过彼此接触可构筑出热二极管(见图5)。该热二极管具有良好的柔性(曲率半径为420 μm)和力学强度(抗拉强度≥7.2 MPa), 同时展现出优异的热整流性能,热整流比可达2.0。该研究实现了宏观柔性热二极管制备,扩展了芳纶纳米纤维气凝胶的应用领域[35]。

图5

图5

芳纶气凝胶薄膜限域相变材料制备热二极管示意图

Fig. 5

Schematic illustration on fabrication strategy of aramid aerogel confined phase change films and assembly mechanism of flexible thermal diode

4 3D打印芳纶气凝胶

3D打印技术,又被称为增材制造技术,是通过层层堆积实现数字模型到实物的构建[41]。利用3D打印技术制备芳纶气凝胶,为芳纶气凝胶的形态多样化提供了可能性。为了适应芳纶纳米纤维分散液的流变特性、溶胶-凝胶成型特性等,已经开发出冷冻-直写3D打印(DIW)以及悬浮基质辅助3D打印制备芳纶气凝胶。

4.1 3D打印芳纶气凝胶制备

4.1.1 直写成型3D打印

图6

图6

直写成型3D打印芳纶纳米纤维气凝胶制备示意图

Fig. 6

Schematic illustration on fabrication strategy of direct ink writing 3D printing process of aramid nanofiber aerogel

冷冻-直写3D打印受限于底部冷源平台,随着打印高度的增加,z轴方向温度逐渐升高,挤出的墨水不能立刻发生溶胶-冻凝胶转变,影响墨水成型,从而使打印结构高度受限。为提升打印高度,一方面可改进冷源,如利用可移动干冰产生冷冻气氛;另一方面调控墨水流变性能,使其摆脱冷源限制,如将聚乙烯醇(PVA)引入ANF分散液中,在60 ℃时,ANF-PVA具有良好的流动性,打印至室温(25 ℃), ANF-PVA即形成有机凝胶,采用常温-直写成型3D打印技术可获得ANF-PVA复合气凝胶[43]。

4.1.2 悬浮基质辅助3D打印

采用直写成型3D打印技术实现了芳纶纳米纤维分散液的可打印性和可编程性,但无法制备任意空间结构的芳纶气凝胶,因为根据重力原理,一物体悬浮表面与垂线夹角大于45°时,该物体就可能坠落。在直写成型3D打印工艺中,墨水完全凝胶前相邻层间黏附力不足以克服自身重力,易导致结构坍塌,从而使打印失败。为突破严苛的 45°规则,实现任意形状芳纶气凝胶的制备,本文研究团队开发出一种通用微凝胶辅助打印策略[44],以卡波姆(Carbopol)作为微凝胶辅助基质。卡波姆在二甲基亚砜中溶胀后,分子链伸展,可转变为微凝胶。该微凝胶的流变性质可通过调控其在二甲基亚砜中的质量分数来调节。此外,卡波姆是质子供体,它可使芳纶纳米纤维中的聚阴离子质子化而形成凝胶;进一步,卡波姆中还可加入交联剂(如1,4-二溴丁烷),促进相邻芳纶纳米纤维间发生交联。

将芳纶纳米纤维分散液墨水按所设计路径打印到基质中,得益于微凝胶基质的辅助作用,墨水在原位部分发生动态溶胶-凝胶转变,以保证墨水不分散,后经静置凝胶老化、微凝胶基质去除、溶剂置换和超临界二氧化碳干燥等步骤,得到相应悬浮基质辅助3D打印芳纶气凝胶(见图7)。

图7

图7

悬浮基质辅助3D打印芳纶纳米纤维气凝胶示意图

Fig. 7

Schematic illustration of microgel-directed suspended printing strategy for preparation of 3D aramid nanofiber aerogel with spatially stereoscopic structures

采用悬浮基质辅助3D打印策略,可获得任意可编程图案,如波浪线、阿基米德螺旋线、回文线等。还可制备出任意空间结构的芳纶气凝胶,如倒置锥形烧瓶、挠性软管、蜗牛壳、空心球等壳体结构。悬浮基质辅助3D打印策略展现出了广阔的设计空间。

4.2 3D打印芳纶气凝胶的性能

3D打印芳纶气凝胶具有可设计的力学性能,芳纶气凝胶继承芳纶优异的力学性能,3D打印又赋予其任意形状,通过简单结构设计即可实现力学性能的定制,如抗剪切、抗冲击、抗压痕等。普通格子条带结构的3D打印芳纶气凝胶可以任意扭曲、折叠、卷曲,具有良好的柔韧性。将负泊松比结构引入可获得拉胀芳纶气凝胶,实验分析和理论模拟显示,纳米纤维网络结构和多级断裂机制使其具有超强的吸能特性(约为80 J/g)[21]。进一步,将六角蜂窝结构引入到3D打印芳纶气凝胶中,获得具有优异缓冲性能和高力学性能的轻质芳纶气凝胶蜂窝材料。

3D打印芳纶气凝胶保持气凝胶典型的高比表面积和低导热率(约为0.036 W/(m·K))特性,其隔热保温性能与打印密度和厚度密切相关。通过调控打印密度和厚度,可获得不同隔热保温效果。厚度为3 mm的3D打印芳纶气凝胶,外界温度为 -100 ℃ 时,气凝胶表面温度为-16 ℃,温差达到84 ℃[44]。

4.3 3D打印芳纶气凝胶的应用

3D打印芳纶气凝胶具有形状可设计性,可实现三维复杂结构一体化成型,为特殊形状物体隔热保温提供了发展空间。例如,无人机锂聚合物软包电池具有不规则外形,本文研究团队利用3D打印技术为其量身定制了一种组合保温套件。得益于芳纶气凝胶良好的隔热性能和耐极端高低温性能,在极低温环境下,由该3D打印保温套件保护的电池仍可以正常工作[44]。

3D打印芳纶气凝胶除直接应用,还可作为结构可设计多孔骨架,负载功能流体,获得不同功能的复合材料。例如,负载相变材料可获得热刺激驱动的形状记忆材料,在新型传感器、执行器和机械设备方面具有应用潜力。将3D打印芳纶气凝胶限定为蜂窝结构,相变材料选择具有剪切变硬效应的材料,二者复合可获得优异的抗冲击性能,在柔性智能防护领域具有广阔应用前景。

5 结束语

鉴于目前对高性能气凝胶材料的迫切需求,以芳纶纳米纤维为基本构筑单元的气凝胶材料研究一直保持快速发展态势。本文以芳纶纳米纤维气凝胶为主题,对国内外相关研究成果进梳理。主要对构筑单元芳纶纳米纤维的制备及流变学行为进行总结;并对芳纶气凝胶纤维、芳纶气凝胶薄膜以及3D打印芳纶气凝胶的制备、性能、应用进行凝练。

当前芳纶纳米纤维气凝胶的发展阶段仍属于初期探索阶段。一方面,芳纶纳米纤维气凝胶制备技术不成熟,与传统纤维、薄膜、3D打印技术结合不深入,存在诸多亟需提升的要点如溶剂置换、干燥等过程尚未实现连续化;另一方面,芳纶纳米纤维气凝胶的性能极限尚未达到,如力学性能仍有提升空间。因此,仍需加快芳纶纳米纤维气凝胶研究进程,优化其制备技术、提升其性能、降低其生产成本,以实现在热管理、智能防护以及分离过滤等领域的广泛应用。

参考文献

Chemistry of aerogels and their applications

[J].

Silica aerogel: synthesis, properties and characterization

[J].DOI:10.1016/j.jmatprotec.2007.10.060 URL [本文引用: 1]

柔性气凝胶材料的制备及应用研究进展

[J].

Research progress on preparation and application of flexile aerogel materials

[J].

Uranium removal from aqueous solutions by aerogel-based adsorbents: a critical review

[J].

Preparation of aerogel-like silica foam with the hollow-sphere-based 3D network skeleton by the cast-in situ method and ambient pressure drying

[J].

DOI:10.1021/acs.nanolett.2c02768

PMID:36404639

[本文引用: 1]

Silica aerogels have incomparable advantages among thermal insulation materials because of their ultralow density and thermal conductivity, but cumbersome production processes, high cost, and low mechanical stability limit their practical application. In this study, a novel aqueous process to prepare lightweight aerogel-like silica foams (ASFoams) through the cast-in situ method and ambient pressure drying was proposed with multiblock polyurethane surfactant as the vesicle template. ASFoams possess a unique loose stacking morphology of the silica hollow sphere with a 3D network structure as the skeleton, which endues ASFoams with a low density of 0.059 g/cm, low thermal conductivity of 36.1 mW·k·m, and pretty good mechanical properties. These properties make ASFoams a promising option for thermal insulation in industrial, aerospace, and other extreme environmental conditions. In addition, the micromorphology of ASFoams can be adjusted by changing the reaction conditions, which may provide a facile method for the preparation of a silica aerogel-like foam with adjustable microstructure.

Emerging hierarchical aerogels: self-assembly of metal and semiconductor nanocrystals

[J].

Cellulose aerogel membranes with a tunable nanoporous network as a matrix of gel polymer electrolytes for safer lithium-ion batteries

[J].

Multifunctional aramid nanofiber/carbon nanotube hybrid aerogel films

[J].

DOI:10.1021/acsnano.9b07459

PMID:31851483

[本文引用: 3]

Lightweight, robust, and thin aerogel films with multifunctionality are highly desirable to meet the technological demands of current society. However, fabrication and application of these multifunctional aerogel films are still significantly underdeveloped. Herein, we demonstrate a multifunctional aerogel film composed of strong aramid nanofibers (ANFs), conductive carbon nanotubes (CNTs), and hydrophobic fluorocarbon (FC) resin. The obtained hybrid aerogel film exhibits large specific surface area (232.8 m·g), high electrical conductivity (230 S·m), and excellent hydrophobicity (contact angle of up to 137.0°) with exceptional Joule heating performance and supreme electromagnetic interference (EMI) shielding efficiency. The FC coating renders the hydrophilic ANF/CNT aerogel films hydrophobic, resulting in an excellent self-cleaning performance. The high electrical conductivity enables a low-voltage-driven Joule heating property and an EMI shielding effectiveness (SE) of 54.4 dB in the X-band at a thickness of 568 μm. The specific EMI SE is up to 33528.3 dB·cm·g, which is among the highest values of typical metal-, conducting-polymer-, or carbon-based composites. This multifunctional aerogel film holds great promise for smart garments, electromagnetic wave shielding, and personal thermal management systems.

先进芳纶绝缘纸基材料研究进展及展望

[J].

Progress and prospect of advanced aramid insulating paper-based materials

[J].

Recent advances of 2D materials in nonlinear photonics and fiber lasers

[J].

纳米纤维组织工程支架及其纳米效应研究进展

[J].

Research and development of nanofibrous scaffolds for tissue engineering and their nanoeffects

[J].

Fabrication, applications, and prospects of aramid nanofiber

[J].

Preparation of aromatic polyamide polyanions a novel processing strategy for aromatic polyamides

[J].DOI:10.1021/ma00206a026 URL [本文引用: 1]

Dispersions of aramid nanofibers: a new nanoscale building block

[J].

DOI:10.1021/nn2014003

PMID:21800822

[本文引用: 1]

Stable dispersions of nanofibers are virtually unknown for synthetic polymers. They can complement analogous dispersions of inorganic components, such as nanoparticles, nanowires, nanosheets, etc. as a fundamental component of a toolset for design of nanostructures and metamaterials via numerous solvent-based processing methods. As such, strong flexible polymeric nanofibers are very desirable for the effective utilization within composites of nanoscale inorganic components such as nanowires, carbon nanotubes, graphene, and others. Here stable dispersions of uniform high-aspect-ratio aramid nanofibers (ANFs) with diameters between 3 and 30 nm and up to 10 μm in length were successfully obtained. Unlike the traditional approaches based on polymerization of monomers, they are made by controlled dissolution of standard macroscale form of the aramid polymer, that is, well-known Kevlar threads, and revealed distinct morphological features similar to carbon nanotubes. ANFs are successfully processed into films using layer-by-layer (LBL) assembly as one of the potential methods of preparation of composites from ANFs. The resultant films are transparent and highly temperature resilient. They also display enhanced mechanical characteristics making ANF films highly desirable as protective coatings, ultrastrong membranes, as well as building blocks of other high performance materials in place of or in combination with carbon nanotubes.© 2011 American Chemical Society

Timesaving, high-efficiency approaches to fabricate aramid nanofibers

[J].

DOI:10.1021/acsnano.9b02258

PMID:31244045

[本文引用: 1]

Aramid nanofibers (ANFs) have become promising nanoscale building blocks due to their extraordinary performance. However, there are numerous challenges related to the preparation of ANFs, such as the lengthy preparation cycle (7-10 days), low preparation concentration (0.2 wt %), and high difficulty in quantitatively judging the end point of the deprotonation reaction. Herein, we report three time-saving and high-efficiency strategies (fibrillation, ultrasonication, and proton donor-assisted deprotonation) to prepare ANFs with excellent performance. The fiber micromorphology during the deprotonation and protonation recovery processes was first investigated. Then the end point of the deprotonation reaction was detected by Raman spectra and the cationic demand of the ANF/DMSO system. Finally, the size, preparation cycle, and performance of the corresponding ANFs and ANF films fabricated by different approaches were investigated in detail. The results showed that proton donor-assisted deprotonation significantly shortened the traditional preparation cycle from 7 days to 4 h, and is the most efficient method reported thus far. It is noteworthy that a high concentration of ANFs (4.0 wt %) could also be achieved within 12 h. Interestingly, the fabricated ANFs exhibit rigid morphology and a small diameter with a narrow size distribution (10.7 ± 1.0 nm). The resultant ANF film displays desired characteristics of high strength and toughness. The work offers a timesaving, feasible and effective strategy to realize the large-scale production for ANFs, which will facilitate the application of ANFs in the production of advanced nanomaterials.

Fabrication and characterization of differentiated aramid nanofibers and transparent films

[J].DOI:10.1007/s13204-018-0722-z [本文引用: 1]

Nonstop monomer-to-aramid nanofiber synthesis with remarkable reinforcement ability

[J].DOI:10.1021/acs.macromol.8b02391 URL [本文引用: 1]

A new approach to the preparation of poly(p-phenylene terephthalamide) nanofibers

[J].DOI:10.1039/C6RA01602B URL [本文引用: 1]

Electrospinning: a fascinating method for the preparation of ultrathin fibers

[J].

DOI:10.1002/anie.200604646

PMID:17585397

[本文引用: 1]

Electrospinning is a highly versatile method to process solutions or melts, mainly of polymers, into continuous fibers with diameters ranging from a few micrometers to a few nanometers. This technique is applicable to virtually every soluble or fusible polymer. The polymers can be chemically modified and can also be tailored with additives ranging from simple carbon-black particles to complex species such as enzymes, viruses, and bacteria. Electrospinning appears to be straightforward, but is a rather intricate process that depends on a multitude of molecular, process, and technical parameters. The method provides access to entirely new materials, which may have complex chemical structures. Electrospinning is not only a focus of intense academic investigation; the technique is already being applied in many technological areas.

Electrospinning of p-aramid fibers

[J].DOI:10.1002/mame.201500130 URL [本文引用: 1]

3D printing-directed auxetic kevlar aerogel architectures with multiple functionalization options

[J].DOI:10.1039/D0TA02590A URL [本文引用: 4]

Nanoscale kevlar liquid crystal aerogel fibers

[J].

DOI:10.1021/acsnano.2c06591

PMID:36053080

[本文引用: 5]

Aerogel fibers, the simultaneous embodiment of aerogel porous network and fiber slender geometry, have shown critical advantages over natural and synthetic fibers in thermal insulation. However, how to control the building block orientation degree of the resulting aerogel fibers during the dynamic sol-gel transition process to expand their functions for emerging applications is a great challenge. Herein, nanoscale Kevlar liquid crystal (NKLC) aerogel fibers with different building block orientation degrees have been fabricated from Kevlar nanofibers liquid crystal spinning, dynamic sol-gel transition, freeze-drying, and cold plasma hydrophobilization in sequence. The resulting NKLC aerogel fibers demonstrate extremely high mechanical strength (41.0 MPa), excellent thermal insulation (0.037 W·m·K), and self-cleaning performance (with a water contact angle of 154°). The superhydrophobic NKLC aerogel fibers can cyclically transform between aerogel and gel states, while gel fibers involving different building block orientation degrees display distinguishable brightness under polarized light. Based on these performances, digital textiles woven or embroidered with high- and low-orientated NKLC aerogel fibers enable up to 6.0 Gb information encryption in one square meter and on-demand decryption. Therefore, it can be envisioned that the tuning of the building blocks' orientation degree will be an appropriate strategy to endow performance to the liquid crystal aerogel fibers for potential applications beyond thermal insulation.

Modern inorganic aerogels

[J].DOI:10.1002/anie.201611552 URL [本文引用: 1]

Ultrathin cellulose nanofiber assisted ambient-pressure-dried, ultralight, mechanically robust, multifunctional mxene aerogels

[J].

纳米芳纶气凝胶纤维的制备与微观结构调控

[J].

Preparation and microstructure control of aerogel fibers based on aramid nanofibers

[J].

Nanofibrous kevlar aerogel threads for thermal insulation in harsh environments

[J].

DOI:10.1021/acsnano.9b01094

PMID:31042355

[本文引用: 3]

Aerogel with low density, high porosity, and large surface area is a promising structure for the next generation of high-performance thermal insulation fibers and textiles. However, aerogel fibers suffer from weak mechanical properties or complex fabricating processes. Herein, a facile wet-spinning approach for fabricating nanofibrous Kevlar (KNF) aerogel threads ( i.e., aerogel fibers) with high thermal insulation under extreme environments is demonstrated. The aerogel fibers made from nanofibrous Kevlar render a high specific surface area (240 m/g) and wide-temperature thermal stability. The flexible and strong KNF aerogel fibers are woven into textiles to illustrate the excellent thermal insulation property under extreme temperature (-196 or +300 °C) and at room temperature. COMSOL simulation is applied to calculate the thermal conductivity of a single aerogel fiber and find an effective way to improve the thermal insulation property of the aerogel fiber. Furthermore, a series of functionalized fibers or textiles based on KNF aerogel fibers, such as phase-change fibers, conductive fibers, and hydrophobic textiles, have been prepared. Such KNF aerogel fibers represent a promising direction for the next generation of high-performance fibrous thermal-insulation materials.

Bending stiffness-directed fabricating of kevlar aerogel-confined organic phase-change fibers

[J].

DOI:10.1021/acsnano.1c05693

PMID:34423639

[本文引用: 4]

Smart and functional fibers have demonstrated great potentials in a wide range of applications including wearable devices and other high-tech fields, but design and fabrication of smart fibers with manageable structures as well as versatile functions are still a great challenge. Herein, an ingenious bending-stiffness-directed strategy is developed to fabricate smart phase-change fibers with different bending stiffnesses for diverse applications. Specifically, the hydrophobic Kevlar aerogel-confined paraffin wax fibers (PW@H-KAF) are fabricated by employing hydrophobic Kevlar aerogel fibers (H-KAFs) as the porous host and paraffin as the functional guest, where the H-KAF is obtained by applying a two-step process to functionalize Kevlar nanofibers (KNFs) with a special coagulation bath containing a mixture of ethanol and -bromobutane. The prepared PW@H-KAFs exhibit high latent heat (135.1-172 J/g), outstanding thermal cyclic stability and satisfactory mechanical properties (30 MPa in tensile strength and 30% in tensile strain). In addition, the PW@H-KAFs with bending stiffness was lower than the critical one (1.22 × 10 N·m) even in a solid state of paraffin wax exhibits high flexibility, washable performance, and high thermal management capability, showing great potential for smart temperature-regulating fabrics. PW@H-KAFs with a bending stiffness higher than the critical one at a solid state of paraffin wax can be utilized as shape memory materials, attributed to the transition between rigidity and flexibility caused by the phase transition. As a proof of concept, a dynamic gripper is designed based on the PW@H-KAF (400 μm in diameter) for transporting items by gripping in the rigid state and releasing in the flexible state. This work realizes versatile applications with the PW@H-KAFs through the bending stiffness-directed method, providing ideas for the application of phase-change composites.

Symbiotic aerogel fibers made via in-situ gelation of aramid nanofibers with polyamidoxime for uranium extraction

[J].

Structural control of silica aerogel fibers for methylene blue removal

[J].DOI:10.1007/s11431-018-9389-7 [本文引用: 1]

The aramid-coating-on-aramid strategy toward strong, tough, and foldable polymer aerogel films

[J].

DOI:10.1021/acsnano.2c04572

PMID:35994616

[本文引用: 3]

Aerogel has been much highlighted as an emerging lightweight thermal insulation material, but problems such as fragility, low strength, liquid permeability, and lack of flexibility greatly limit further applications. In this work, a facile aramid-coating-on-aramid (ACoA) method is demonstrated to fabricate all-aramid aerogel composite films for thermal insulation. The method started from the bottom-up synthesis of polymerization-induced -aramid nanofibers (PANF), which were easily transformed into aerogel films through the vacuum-assisted filtration followed by the freeze-drying techniques. Then, the heterocyclic aramid (HA) solution prepared through the low-temperature-solution polycondensation was used as the coating to be applied onto the PANF aerogel films, and composite films of HA/PANF aerogel were simply achieved with HA contributed to the dense and continuous surface layer. The bulk HA film is of superior mechanical and thermal properties to those of the PANF film. Moreover, reliable interfacial interlocking structures were developed beneath the outermost surface via the interpenetration of the infiltrated HA with PANF network. The comprehensive result was the 15 times enhanced tensile strength, 33 times enhanced fracture toughness, the high thermal decomposition temperature, and the additional flexibility for the foldable films of HA/PANF aerogel. The sealing of the surface macropores greatly suppressed the surface chalking and high water absorption. However, the survival of the tiny pores inside the composite maintained the low enough level of the thermal conductivity to provide effective protections against high temperature not only in air but also under wet or even liquid conditions, suggesting the broader applications for thermal insulation.

Nanofibrous kevlar aerogel films and their phase-change composites for highly efficient infrared stealth

[J].

DOI:10.1021/acsnano.8b08913

PMID:30697999

[本文引用: 4]

Infrared (IR) stealth is essential not only in high technology and modern military but also in fundamental material science. However, effectively hiding targets and rendering them invisible to thermal infrared detectors have been great challenges in past decades. Herein, flexible, foldable, and robust Kevlar nanofiber aerogel (KNA) films with high porosity and specific surface area were fabricated first. The KNA films display excellent thermal insulation performance and can be employed to incorporate with phase-change materials (PCMs), such as polyethylene glycol, to fabricate KNA/PCM composite films. The KNA/PCM films with high thermal management capability and infrared emissivity comparable to that of various backgrounds demonstrate high performance in IR stealth in outdoor environments with solar illumination variations. To further realize hiding hot targets from IR detection, combined structures constituted of thermal insulation layers (KNA films) and ultralow IR transmittance layers (KNA/PCM) are proposed. A hot target covered with this combined structure becomes completely invisible in infrared images. Such KNA/PCM films and KNA-KNA/PCM combined structures hold great promise for broad applications in infrared thermal stealth.

Ultralight nanofibre-assembled cellular aerogels with superelasticity and multifunctionality

[J].

Anisotropic, lightweight, strong, and super thermally insulating nanowood with naturally aligned nanocellulose

[J].

A thermally insulating textile inspired by polar bear hair

[J].

Nanoporous kevlar aerogel confined phase change fluids enable super-flexible thermal diodes

[J].

High strength conductive composites with plasmonic nanoparticles aligned on aramid nanofibers

[J].DOI:10.1002/adfm.v26.46 URL [本文引用: 1]

Laminated structural engineering strategy toward carbon nanotube-based aerogel films

[J].DOI:10.1021/acsnano.2c02193 URL [本文引用: 1]

Aramid nanofiber aerogel membrane extract from waste plastic for efficient separation of surfactant-stabilized oil-in-water emulsions

[J].

Carbon nanotube-multilayered graphene edge plane core-shell hybrid foams for ultrahigh-performance electromagnetic-interference shielding

[J].

Flame-retardant host-guest films for efficient thermal management of cryogenic devices

[J].

Scalable submicrometer additive manufacturing

[J].

DOI:10.1126/science.aax8760

PMID:31604310

[本文引用: 1]

High-throughput fabrication techniques for generating arbitrarily complex three-dimensional structures with nanoscale features are desirable across a broad range of applications. Two-photon lithography (TPL)-based submicrometer additive manufacturing is a promising candidate to fill this gap. However, the serial point-by-point writing scheme of TPL is too slow for many applications. Attempts at parallelization either do not have submicrometer resolution or cannot pattern complex structures. We overcome these difficulties by spatially and temporally focusing an ultrafast laser to implement a projection-based layer-by-layer parallelization. This increases the throughput up to three orders of magnitude and expands the geometric design space. We demonstrate this by printing, within single-digit millisecond time scales, nanowires with widths smaller than 175 nanometers over an area one million times larger than the cross-sectional area.Copyright © 2019 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Generalized 3D printing of graphene-based mixed-dimensional hybrid aerogels

[J].

DOI:10.1021/acsnano.8b00304

PMID:29613763

[本文引用: 1]

Graphene-based mixed-dimensional materials hybridization is important for a myriad of applications. However, conventional manufacturing techniques face critical challenges in producing arbitrary geometries with programmable features, continuous interior networks, and multimaterials homogeneity. Here we propose a generalized three-dimensional (3D) printing methodology for graphene aerogels and graphene-based mixed-dimensional (2D + nD, where n is 0, 1, or 2) hybrid aerogels with complex architectures, by the development of hybrid inks and printing schemes to enable mix-dimensional hybrids printability, overcoming the limitations of multicomponents inhomogeneity and harsh post-treatments for additives removal. Importantly, nonplanar designed geometries are also demonstrated by shape-conformable printing on curved surfaces. We further demonstrate the 3D-printed hybrid aerogels as ultrathick electrodes in a symmetric compression tolerant microsupercapacitor, exhibiting quasi-proportionally enhanced areal capacitances at high levels of mass loading. The excellent performance is attributed to the sufficient ion- and electron-transport paths provided by the 3D-printed highly interconnected networks. The encouraging finding indicates tremendous potentials for practical energy storage applications. As a proof of concept, this general strategy provides avenues for various next-generation complex-shaped hybrid architectures from microscale to macroscale, for example, seawater desalination devices, electromagnetic shielding systems, and so forth.

3D printed hybrid aerogel gauzes enable highly efficient hemostasis

[J].

General suspended printing strategy toward programmatically spatial kevlar aerogels

[J].

DOI:10.1021/acsnano.2c00720

PMID:35230080

[本文引用: 3]

Aerogels represent a kind of nanoporous solid with immense importance for a plethora of diverse applications. However, on-demand conformal shaping capacity remains extremely challenging due to the strength unfavorable during aerogel processing. Herein, a universal microgel-directed suspended printing (MSP) strategy is developed for fabricating various mesoporous aerogels with spatially stereoscopic structures on-demand. As a proof-of-concept demonstration, through the rational design of the used microgel matrix and favorable printing of the Kevlar nanofiber inks, the Kevlar aerogels with arbitrary spatial structure have been fabricated, demonstrating excellent printability and programmability under a high-speed printing mode (up to 167 mm s). Furthermore, the custom-tailored Kevlar aerogel insulator possessing superior thermal insulation attribute has ensured normal discharge capacity of the drone even under a harsh environment (-30 °C). Finally, various types of spatial 3D aerogel architectures, including organic (cellulose, alginate, chitosan), inorganic (graphene, MXene, silica), and inorganic-organic (graphene/cellulose, MXene/alginate, silica/chitosan) hybrid aerogels, have been successfully fabricated, suggesting the universality of the MSP strategy. The strategy reported here proposes an alternative for the development of various customized aerogels and stimulates the inspiration to truly arbitrary architectures for wider applications.

京公网安备11010502044800号

京公网安备11010502044800号