芳纶作为高性能有机纤维的典型代表,因其轻质、高强、耐热和透波的突出特性,已成为高性能纤维领域最重要的品种之一,但芳纶本征刚性较强的分子主链结构及其分子链间较高的内聚能密度使得其表面光滑、致密,表现出较大的惰性,限制了芳纶更为广泛的应用。例如,芳纶表面较低的染色牢度造成印花工序中更高的加工难度,限制了其在家用装饰、汽车座椅等民用领域的应用。除此之外,更为关键的是芳纶作为树脂基复合材料的重要增强体[1⇓-3],其复合材料制件的实际结构也往往由于芳纶的惰性表面而形成薄弱的界面[4⇓-6],限制了芳纶增强复合材料的实际使用性能,这也成为了芳纶应用领域的关键难点问题之一。从复合材料的结构来讲,高性能纤维增强的复合材料具有典型的多相结构,主要包括以聚合物基体组成的基体相和高性能纤维组成的增强相。基体相承担着复合材料成型以及保护纤维预制体的功能;增强相则承担着外界施加到复合材料制件上的绝大部分应力载荷。复合材料除存在上述基体相与增强相以外,还存在着不可或缺的第三相——界面相。

由于界面相兼具纤维和树脂二相的化学结构特点,因此,通过优化纤维与树脂的黏接行为来改善界面相的性能则是解决这一问题的常见策略,而这主要是通过对纤维的表面处理来实现的[7⇓⇓-10]。实际上,对于利用纤维的表面处理来改善复合材料的界面性能早已有诸多报道[11⇓⇓-14],例如酸碱刻蚀、等离子体处理、辐照处理以及化学接枝等。总的来讲,上述技术手段的应用无不围绕以下2点:一是提高纤维的表面极性或引入活性位点,使树脂预聚物在纤维表面具有更好的浸润性,甚至与之产生化学键合;二是提高纤维表面的粗糙度,使得树脂基体能够与纤维表面产生机械锁合,进而抑制界面脱黏。事实证明,围绕纤维极性与粗糙度进行界面结构调控的复合材料增强体表面处理方法,的确可以有效优化宏观复合材料制件的整体性能。而在这当中,关于界面化学结构与形态结构以及界面细观力学的定量认识却几乎是空白。随着复合材料制件服役环境的日渐复杂化,行业迫切需要界面结构清晰和性能可控的复合材料界面设计方法,以推进行业内对不同应用场景下复合材料制件的定制化设计与制备。

直接氟化技术是近年来越来越受到关注的一种材料表面处理技术,因其在材料表面引入相对明晰的含氟结构及其可设计性的优势,近年来在高性能纤维表面处理领域也得到了长足的发展。本文从直接氟化的原理出发,总结了近些年来利用直接氟化技术对芳纶表面处理、增强复合材料界面结构设计的研究成果,以及直接氟化技术在高性能纤维表面处理领域的应用及其衍生修饰的发展历程,并提出了直接氟化技术现有的不足和在未来复合材料界面结构设计中的发展趋势。

1 直接氟化技术概述

2 直接氟化及其衍生反应的应用

2.1 基于直接氟化调控纤维的表面结构与极性

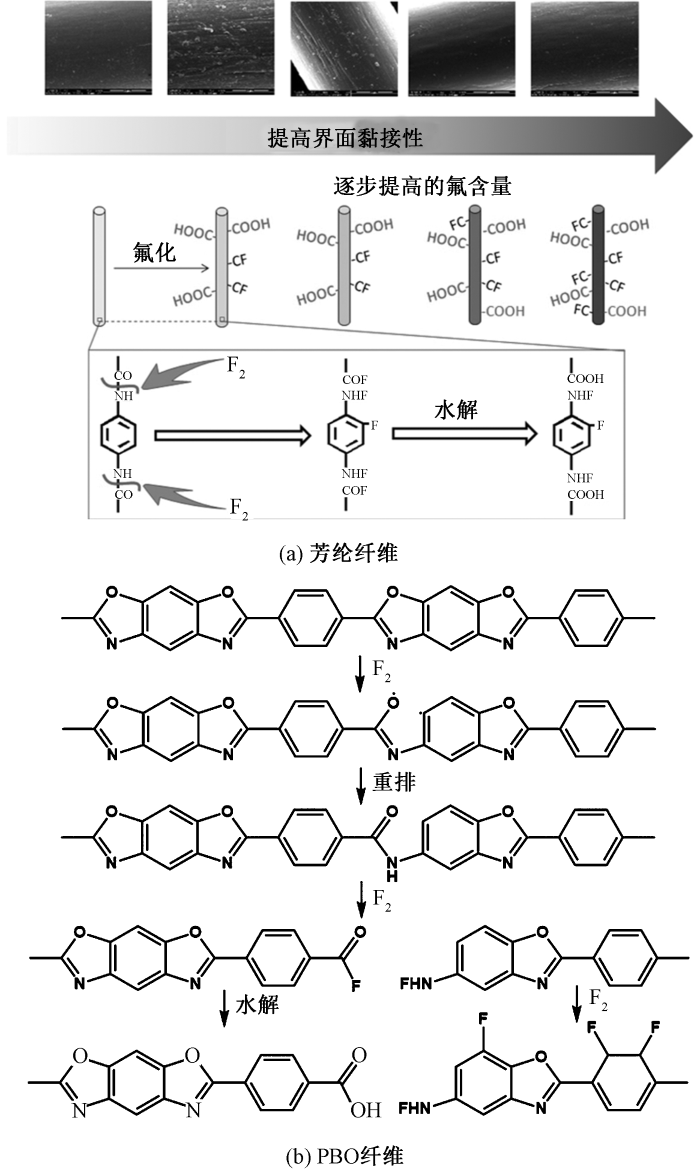

由于氟原子拥有已知元素中最高的电负性,直接氟化可在纤维表面以共价键的方式引入C—F等极性基团,进而大幅改善纤维表面与聚合物基体浸润性差的问题。例如,Cheng等[21]利用F2/N2混合气体对杂环芳纶进行直接氟化处理,在分析了氟气与芳纶表面大分子链的反应历程后发现,纤维表面新增的极性基团主要有2个来源(见图1(a)[21]):一是氟气与芳纶主链苯环上的氢原子发生取代反应,在苯环上原位生成含C—F的氟苯结构;二是随着纤维主链苯环结构氟化反应的进行,氟气将进一步进攻酰胺键并取代到羰基碳原子上生成酰氟基团,并进一步水解生成羧基等含氧官能团。直接氟化处理后的芳纶表面大量的极性官能团显著改善了纤维与树脂基体的浸润性,其与树脂复合的拔出强度最大提高了39.53%。这一界面增强效果同样在对聚对苯撑苯并二噁唑(PBO)纤维的表面氟化研究中也得到了证实(见图1(b))[22]。

图1

图1

直接氟化处理芳纶纤维和PBO纤维的反应机制

Fig. 1

Mechanism of direct fluorination in aramid(a) and PBO(b) fiber

直接氟化引入到芳纶表面的含氧官能团主要是依赖主链上酰胺键的断裂和水解产生的,那么在较高氟化程度下,过多的酰胺键断裂是否会影响纤维本征良好的力学强度,对于芳纶的应用具有重要意义。为此,Luo等[23]通过制备不同氟化程度的芳纶,对比研究了纤维的表面状态和力学强度,证实了芳纶表面氟原子分数低于10.5%时,纤维的拉伸强度基本维持不变;而当氟化程度较高,纤维表面的氟原子分数高于这一阈值时,芳纶的拉伸强度将会下降。

为在改善芳纶与聚合物基体浸润效果的同时维持其本征优异的力学强度,Cheng等[24]借助含咪唑的杂环芳纶为研究对象,通过简单的金属盐溶液浸泡的方法,将过渡族金属离子以配位键的形式络合在咪唑C=N的氮原子上,再进行直接氟化处理;借助有机化学中过渡金属离子催化卤素单质与芳烃发生取代反应的原理,氟气与主链络合有金属离子的芳纶进行氟化反应时,将主要与大分子链上邻近络合位点的苯环发生选择性氟化反应(见图2[24])。傅里叶红外光谱实验结果表明,在金属离子催化作用的保护下,氟化后芳纶表面的含氧官能团比例大幅度下降,说明纤维的断链现象被大幅度抑制;拉伸实验测得氟化后纤维保持较好的拉伸强度也证实了这一点。同时,由于纤维表面得以“承受”更高的氟化程度,催化氟化处理后的芳纶也得以表现出了更高的复合材料界面剪切强度。

图2

图2

金属离子催化选择性氟化芳纶纤维的机制示意图

Fig. 2

Mechanism of metal-ion catalyst selective direct fluorination

2.2 氟化纤维表面衍生接枝反应改性

直接氟化反应可在保持纤维本征力学强度的基础上向纤维表面引入较高含量的含氟和含氧等极性基团,并且可在苯环上引入C—F。由于共轭效应,苯环上的C—F具有化学反应活性,即苯环上的 C—F 可与含氨基等亲核试剂发生取代反应,从而可直接氟化引入芳香族C—F作为新的活性中心,在芳纶表面大分子链上进行衍生接枝反应,进一步为芳纶表面共价键修饰的结构调控提供新的途径。例如,Cheng等[25]利用C—F键与硅烷偶联剂KH550上氨基的亲核反应能力的性质,在芳纶表面接枝大量Si—OH基团,使得芳纶具有类似于玻璃纤维的表面结构与表面性质,因而可以在这一基础上进一步利用硅烷偶联剂对芳纶进行高密度接枝修饰。二步法硅烷偶联剂修饰后的纤维复丝与环氧树脂的黏接强度提高了46.7%。

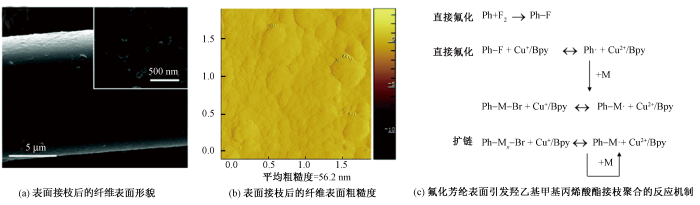

此外,启发自原子转移自由基聚合当中以卤代烃为活性中心的特点,He等[26]进一步在氟化芳纶表面借助C—F的反应活性,引发了羟乙基甲基丙烯酸酯与芳纶的原子转移自由基聚合反应。研究结果显示,羟乙基甲基丙烯酸酯在C—F键的作用下能够有效地发生连锁聚合反应,并能够在纤维表面形成均匀、明显的包覆层(见图3[26])。原子力显微镜测试结果显示,聚-羟乙基甲基丙烯酸酯将芳纶的表面粗糙度从38.4 nm提高到了56.2 nm;此外,聚-羟乙基甲基丙烯酸酯接枝层在芳纶表面引入的大量含氧基团,显著提高了纤维的表面极性,其水接触角从原始纤维的105.1°降到了76.5°。因此,在纤维表面粗糙度和极性的共同调控下,以C—F为活性中心引发原子转移自由基聚合反应修饰的芳纶增强复合材料的界面剪切强度从29.6 MPa提高到了39.0 MPa,表现出更好的界面相容性和结合强度。

图3

图3

氟化芳纶表面引发羟乙基甲基丙烯酸酯接枝聚合的原理及其表面形貌

注:Ph和Bpy分别代表苯环和2,2'-联吡啶。

Fig. 3

Mechanism in fluorinated aramid fiber initiating polymerization of hydroxyethyl methacrylate and its surface topography.

(a)Surface morphology of grafted fibers;(b)Surface roughness of grafted fibers;(c)Mechanism in fluorinated aramid fiber initiating polymerization of hydroxyethyl methacrylate

2.3 纤维表面连锁聚合改性

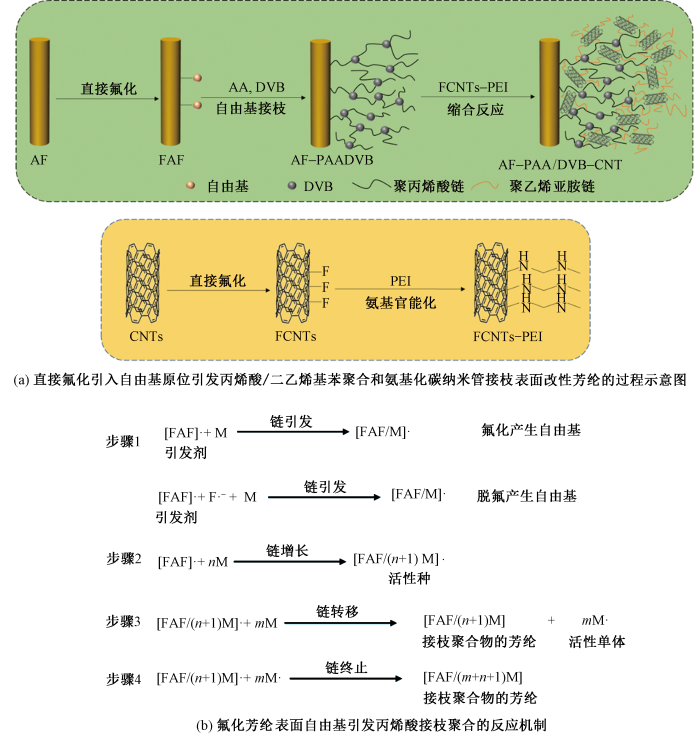

文献[31]借助电子顺磁波谱进一步对氟化芳纶进行表征,首次检测到了氟化后芳纶中的氟相关自由基信号,并以此作为自由基反应位点,在纤维表面原位引发了丙烯酸(AA)/二乙烯基苯(DVB)的自由基共聚接枝聚合反应,并进一步将氨基化多壁碳纳米管以共价键的方式同时接枝到了纤维表面,在增强芳纶表面极性的同时,赋予了纤维表面粗糙度,共同改善了芳纶增强复合材料的界面性能;其界面剪切强度(IFSS)可提高69.1%。除此之外,基于不同改性阶段纤维不同的表面极性和表面粗糙度,进一步提出了一种半定量描述纤维表面不同结构特征对复合材料界面剪切强度影响机制的数学模型[31],对复合材料界面细观力学及其内禀机制的研究进行了初步尝试(见图4[31])。初步研究结果表明,相比于纤维表面粗糙度,纤维表面极性对于提高复合材料的界面剪切强度具有更高的贡献率。

图4

图4

直接氟化引入自由基引发的芳纶表面自由基聚合反应过程和机制

Fig. 4

Reaction process(a)and mechanism(b)of surface radical polymerization of aramid fibers initiated by direct fluorination

3 结束语

纤维表面处理及其复合材料界面结构设计仍将是解决未来复合材料力学领域难题的有效途径。前期的研究工作已经证实,直接氟化技术是一种低成本和可工业化应用的纤维表面处理技术,能够在保持纤维本征优异力学性能的基础上,大幅改善纤维表面性质及其与聚合物基体的界面结合,从而改善复合材料中界面相的力学性能。除此之外,利用氟化后引入到纤维表面的C—F键和自由基作为活性衍生反应位点,进一步发展了基于直接氟化的诸多衍生反应,实现了纤维表面的高密度接枝以及复合材料界面结合强度的进一步改善。事实上,直接氟化技术在纤维表面改性及其增强复合材料的界面结构设计和构筑研究中仍有待进一步发展与应用,从而有望更好地解决纤维增强复合材料力学领域发展过程中的潜在科学与技术问题,为纤维表面改性及其复合材料界面性能调控提供新的方法。但直接氟化芳纶表面改性及其复合材料界面研究仍然存在以下3个方面的问题和发展趋势:1)由于氟气化学反应活性高,目前其调控原理和方法不足,如何更有效地调控氟化反应速率和氟化反应位点的选择性,以及如何更有效地避免大分子链的断链行为等是直接氟化技术进一步研究发展的重点;2)如何通过直接氟化反应及其衍生接枝反应,在纤维表面构筑连续梯度变化的极性结构及其界面性能,从而更准确地描述和建立纤维表面物理化学结构对复合材料界面细观力学的定量构效关系;3)建立更高效地调控直接氟化纤维均匀性的方法和相应的工程化装备等。

参考文献

Effect of low melting temperature polyamide fiber-interlaced carbon fiber braid fabric on the mechanical performance and fracture toughness of CFRP laminates

[J].

Reinforcing carbon fibers as sensors: the effect of temperature and humidity

[J].

Tensile strength of CFRP with curvilinearly arranged carbon fiber along the principal stress direction fabricated by the electrodeposition resin molding

[J].

Carbon nanotube enhanced carbon fiber-poly(ether ether ketone) interfaces in model hierarchical composites

[J].

A novel hybrid composites based on biopolyamide 10.10 with basalt/aramid fibers: mechanical and thermal investigation

[J].

High performance aramid pulp/carbon fiber-reinforced polybenzoxazine composites as friction materials

[J].

A comprehensive review on surface modification of UHMWPE fiber and interfacial properties

[J].

Enhancing the interfacial properties of high-modulus carbon fiber reinforced polymer matrix composites via electrochemical surface oxidation and grafting

[J].

Surface modification of aramid fibers by amino functionalized silane grafting to improve interfacial property of aramid fibers reinforced composite

[J].DOI:10.1002/pc.v41.5 URL [本文引用: 1]

Recent advances in basalt-fiber-reinforced composites: tailoring the fiber-matrix interface

[J].

Improvement on strength and toughness for CFRPs by construction of novel "soft-rigid" interface layer

[J].

Carbon fiber polypropylene interphase modification as a route to improved toughness

[J].

π-π interaction between carbon fiber and epoxy resin for interface improvement in composites

[J].

Recent advances of interphases in carbon fiber-reinforced polymer composites: a review

[J].

The action of elementary fluorine upon organic compounds

[J].

表面氟化的环氧/玻璃纤维复合绝缘的表面性能与耐放电性能

[J].

Surface properties and discharge resistance of surface fluorinated epoxy/fiberglass composite insulators

[J].

GIS绝缘子的直接氟化与直流闪络性能

[J].

Direct fluorination and DC flashover performance of GIS spacers

[J].

Modification of asymmetric polysulfone membranes by mild surface fluorination. part 1: transport proper-ties

[J].DOI:10.1016/0376-7388(93)E0153-B URL [本文引用: 1]

Toward excellent tribological performance as oil-based lubricant additive: particular tribological behavior of fluorinated graphene

[J].

Surface modification of fluoroelastomer by direct fluorination with fluorine gas

[J].DOI:10.1016/j.matlet.2014.01.149 URL [本文引用: 1]

Structural evolution of fluorinated aramid fibers with fluorination degree and dominant factor for its adhesion property

[J].DOI:10.1016/j.jfluchem.2016.06.018 URL [本文引用: 2]

Surface modification of PBO fibers by direct fluorination and corresponding chemical reaction mechanism

[J].DOI:10.1016/j.compscitech.2018.06.014 URL [本文引用: 1]

Direct fluorination of para-aramid fibers 1: fluorination reaction process of PPTA fiber

[J].DOI:10.1016/j.jfluchem.2016.04.002 URL [本文引用: 1]

Fe3+ coordination induced selective fluorination of aramid fiber to suppress surface chain scission behavior and improve surface polarity

[J].DOI:10.1016/j.apsusc.2018.06.110 URL [本文引用: 2]

Covalent modification of aramid fibers' surface via direct fluorination to enhance composite interfacial properties

[J].

Direct fluorination as a one-step ATRP initiator immobilization for convenient surface grafting of phenyl ring-containing substrates

[J].DOI:10.1039/D0PY00860E URL [本文引用: 2]

Radical chain reaction mechanism of graphene fluorination

[J].DOI:10.1016/j.carbon.2018.05.005 URL [本文引用: 1]

Direct fluorination of nanographene molecules with fluorine gas

[J].DOI:10.1016/j.carbon.2021.12.043 URL [本文引用: 1]

Covalent functionalization of fluorinated graphene through activation of dormant radicals for water-based lubricants

[J].DOI:10.1016/j.carbon.2020.06.033 URL [本文引用: 1]

In situ radical polymerization and grafting reaction simultaneously initiated by fluorinated graphene

[J].

DOI:10.1021/acs.langmuir.9b00131

PMID:31038966

[本文引用: 1]

Fluorinated graphene (FG) showed interesting electrochemical, electronic, and mechanical properties, as well as chemical reactivity for multifarious functionalization of graphene material. This work reported a free radical polymerization and grafting from polymerization of a styrene monomer directly initiated by FG, which simultaneously provided free polymers and functionalized graphene with polymer chains grafted. The FG exhibited an almost comparative initiation efficiency to equivalent commercial initiator azodiisobutyronitrile under similar conditions, resulting in a high yield of free polystyrene (40.9%) with a high molecular weight ( M = 114.7 kg/mol). It was demonstrated that FG-triggered polymerization presented some special characteristics, such as a long lifetime of chain radical centers even when the reaction was stopped and insensitivity to oxygen molecules. The mechanistic study indicated that the polymerization was initiated by single-electron transfer reaction between FG and a monomer leading to formation of primary radicals; in addition, FG also played an important role in chain transfer and termination reactions during the polymerization process.

In-situ polymerization and covalent modification on aramid fiber surface via direct fluorination for interfacial enhancement

[J].

京公网安备11010502044800号

京公网安备11010502044800号