柔性可穿戴智能织物可在保持传统织物柔软、透气、可延展等优势的基础上,赋予其储能、发光、传感、导电、响应等智能化特征,被认为是下一代柔性可穿戴器件的理想形式之一[1⇓-3]。其中功能纤维构筑是发展智能织物的关键。目前常用的功能纤维制备方法有共聚改性、共混改性和表面改性。共聚改性涉及复杂的化学合成反应,可控性差[4]。共混改性虽工艺简单,但是会降低纤维的物理力学性能[5]。表面改性在不破坏纤维分子结构及力学性能的基础上可实现纤维的快速多功能化;但常用的表面改性方法如等离子体处理、紫外光辐射、碱减量改性及氨解处理具有能耗大、成本高、工艺复杂以及功能单一、稳定性不理想的缺点[6],因此,开发一种简单高效且具有稳定黏附的多功能涂层对制备功能纤维至关重要。

蛋白质淀粉样结构与海洋生物诸如藤壶[7]和微生物大肠杆菌[8]在各种基材表面的黏附密切相关。然而,如何在生物体外实现蛋白质的淀粉样组装一直是个难题。课题组在前期研究中发现,只需在蛋白质水溶液中加入一定量的二硫键还原剂三(2-羧乙基)膦(TCEP),蛋白质就可在接近生理条件的水相温和环境中快速发生相转变,在气/液或固/液界面上发生多级自组装,形成具有类淀粉样聚集结构的纳米薄膜[9]。大量氨基酸残基使薄膜表面同时暴露出多种官能团,如羧基、氨基、羟基、巯基、胍基、烷基链和苯环等。这些基团在有机、无机、金属等各类材料表界面之间通过形成以某种作用力为主(共价、配位、疏水、π-π、氢键、静电等作用力)的多位点黏附机制,实现在不同基材表面的稳定黏附[10]。该纳米薄膜具有绿色环保、高效便捷、灵活可控、无色透明、在界面稳定黏附等特点。针对目前聚合物纤维表面功能化策略中改性工艺复杂、涂层稳定性差的难题,本文提出了一种基于蛋白质类淀粉样聚集的新型纤维表面功能化策略。只需将纤维浸泡在含有功能物质的溶菌酶相转变水溶液中,于室温条件下即可在纤维表面形成稳定的功能化涂层。

1 实验部分

1.1 实验材料与仪器

实验材料:溶菌酶、量子点(CdTe/ZnS)、聚乙二醇(PEG,重均分子量为2 000)、三(2-羧乙基)膦(TCEP)、4-羟乙基哌嗪乙磺酸(HEPES)、硫磺素T(ThT)、三乙胺、二氯甲烷,西格玛奥德里奇(上海)贸易有限公司;硝酸银(AgNO3)、氨水(NH3·H2O),北京天根生化科技有限公司;D-葡萄糖(C6H12O6),天津市天力化学试剂有限公司;N, N-二琥珀酰亚胺基碳酸酯(DSC),上海阿拉丁生化科技股份有限公司;金黄色葡萄球菌(S. aureus)、大肠杆菌(E.coli),山东鲁微生物科技有限公司;强力胶带,3M中国有限公司;聚对苯二甲酸乙二醇酯纤维(简称聚酯纤维,线密度为62 tex)、聚酯织物(经纬纱线密度为62 tex,经纬密分别为347、252根/(10 cm)),市售。

实验仪器:SU8020型场发射扫描电子显微镜(日本日立株式会社);PE-Frontier型红外光谱仪(美国珀金埃尔默股份有限公司);FV1200型激光共聚焦显微镜(日本奥林巴斯公司);CHI660E型电化学工作站(上海辰华仪器有限公司);UTM2013型万能材料试验机(深圳三思纵横科技公司);OCA20型视频光学接触角测量仪(北京奥德利诺仪器有限公司)。

1.2 样品制备

1.2.1 银纳米颗粒涂层改性纤维和织物的制备

将AgNO3(600 mg)溶解于超纯水(10 mL)中,待其完全溶解后,逐滴加入2.5% NH3·H2O直至沉淀消失,然后将银氨(Ag(NH3)2OH)溶液质量浓度和pH值分别调节为30 mg/mL和10.5。分别配制30 mg/mL的D-葡萄糖溶液与0.1、0.2、0.3、0.4和0.5 mg/mL的溶菌酶溶液。取等体积的溶菌酶水溶液和银氨溶液混合,将聚酯纤维浸泡其中5 min后加入相同体积的葡萄糖溶液继续反应,2 h后取出,用超纯水清洗3遍,于50 ℃真空烘箱干燥备用。

银纳米颗粒涂层改性织物的制备方法同上,仅将上述体系中聚酯纤维换成尺寸为25 mm×50 mm的聚酯织物。

1.2.2 量子点改性纤维的制备

配制质量浓度分别为1、2、3、5、7、10 mg/mL的溶菌酶溶液。配制50 mmol/L TCEP溶液,并用5 mol/L的NaOH水溶液将其pH值调节至7。将10 mL溶菌酶溶液与100 μL量子点(CdTe/ZnS)水溶液加入含有聚酯纤维的容器中静置,5 min后加入TCEP溶液继续反应,2 h后取出,用超纯水清洗3遍,于50 ℃真空烘箱干燥备用。

1.2.3 PEG改性纤维和织物的制备

参考课题组已有研究工作[13]制备PEG接枝溶菌酶:称取2 g PEG、0.15 g三乙胺溶于20 mL二氯甲烷中,待PEG充分溶解后继续向溶液中加入0.256 g DSC,室温条件下搅拌反应10 h后用冰乙醚沉淀,得到琥珀酰亚胺活化的PEG。称取0.1 g琥珀酰亚胺活化的PEG和140 mg溶菌酶溶解在pH值为 7.5的HEPES缓冲溶液中,在室温环境下搅拌反应8 h。将反应液透析冻干,得到白色粉末即溶菌酶-PEG偶联物。

改性步骤:配制质量浓度为2 mg/mL的溶菌酶-PEG偶联物水溶液。配制50 mmol/L的TCEP溶液,并用5 mol/L NaOH将其pH值调节至7。将10 mL溶菌酶-PEG偶联物水溶液加入含有聚酯纤维的容器中静置,5 min后加入TCEP溶液继续反应,2 h后取出,用超纯水清洗3遍,于50 ℃真空烘箱干燥备用。

PEG改性织物的制备方法同上,需配制质量浓度分别为1、2、5、7、10 mg/mL的溶菌酶-PEG偶联物水溶液进行改性,并将上述体系中聚酯纤维换成尺寸为25 mm×50 mm的聚酯织物。

1.3 测试与表征

1.3.1 类淀粉样结构表征

采用红外光谱仪测试溶菌酶和纤维的全反射红外吸收,测量范围为4 000~400 cm-1,扫描次数为128。通过PeakFit软件对酰胺I进行分峰处理,分析蛋白质的二级结构变化。

1.3.2 改性纤维形貌和荧光观察

采用场发射扫描电镜对银纳米颗粒涂层改性纤维、量子点改性纤维的形貌进行观察。采用场发射扫描电镜中mapping模式对银纳米涂层改性纤维的元素种类和含量进行测试,得到能谱数据。

在黑暗条件下,将银纳米颗粒涂层改性纤维、量子点改性纤维、PEG改性纤维3种功能纤维完全浸泡在ThT溶液(1 mg/mL)中染色15 min,再用超纯水浸泡(漂洗)10 h。然后用激光共聚焦显微镜拍摄荧光照片,观察是否有绿色荧光。设置激发波长为458 nm。

1.3.3 银纳米颗粒涂层改性纤维和织物性能测试

1.3.3.1 导电性测试

采用电化学工作站对利用不同溶菌酶浓度制备的银纳米颗粒涂层改性纤维进行导电性测试。测试方法:在同一根银纳米颗粒涂层改性纤维中,剪取3段30 mm长度的纤维,分别在其两端涂抹导电银浆(约为10 mm)并用铜胶带固定,得到3组待测样。用导线连接样品至电化学工作站。打开CHI660E程序软件,选择线性扫描伏安法曲线测试,设置恒定电压为1.5 V,观察其电流变化,通过拟合曲线斜率得出电阻。

1.3.3.2 涂层稳定性测试

1) 弯折测试:剪取10 mm长度的银纳米颗粒涂层改性纤维,在其两端涂抹导电银浆并用铜胶带固定。将上述样品固定至万能材料试验机上进行循环拉伸测试,设置位移为5 mm,循环20 000次。同时用导线连接电化学工作站,测试电流-时间曲线,记录其电阻变化率。2) 抗胶带撕拉测试:将胶带粘贴至银纳米颗粒涂层改性纤维后撕下,观察撕拉前后涂层形貌变化,直至裂痕出现,记录抗撕拉次数。

1.3.3.3 抗菌性测试

参照AATCC 147—2011《纺织品的抗菌性:平行划线法》,测试银纳米颗粒涂层改性织物对金黄色葡萄球菌和大肠杆菌的抗菌性能。采用直径为4 mm的接种环。首先将稀释的菌液转移到无菌的琼脂板表面上划出5条平行条纹。随后将测试样品轻柔地放置在琼脂板表面,并尽可能使样品横跨这些条纹。将培养皿放置在37 ℃下培养24 h,观察测试样品周围形成的抑菌带。抑菌带的平均宽度(W)通过公式W=(T-D)/2进行计算。式中:T为测试样品与其周围抑菌区域的总宽度,mm;D为测试样品的宽度,mm。

1.3.4 量子点改性纤维性能测试

采用激光共聚焦显微镜拍摄纤维荧光照片,设置激发波长为480 nm。

量子点改性纤维的稳定性测试方法:剪取30 mm长度的量子点改性纤维,将其固定至万能材料试验机(两端分别固定10 mm)上进行循环拉伸测试,设置循环位移为5 mm,循环20 000次。分别在循环0、5 000、10 000、15 000、20 000次时,取下样品采用激光共聚焦显微镜拍摄荧光照片。

通过视频光学接触角测量仪观察PEG改性聚酯织物,在水滴接触织物时开始计时,接触角为0°时停止计时,此时间即为滴水浸湿时间。

根据GB/T 26253—2010《纺织品 织物透湿性试验方法 第2部分:蒸发法》测试PEG改性聚酯织物的透湿率。

将尺寸为25 mm×50 mm的PEG改性聚酯织物固定在万能材料试验机上进行循环弯折测试,设置循环位移为10 mm,循环20 000次。在循环0、5 000、20 000次时,取下样品分别测试其弯折后的滴水浸湿时间和透湿率。

2 结果与讨论

2.1 类淀粉样结构分析

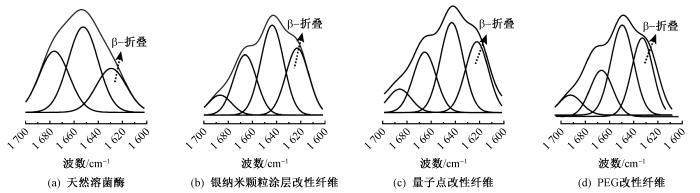

图1为天然溶菌酶和3种功能化改性纤维表面的酰胺Ⅰ带红外光谱分峰图。可以看出,与天然溶菌酶相比,3种功能化改性纤维表面的β-折叠峰面积(约在1 620 cm-1处)明显增加,即β-折叠结构的含量显著增加。

图1

图1

天然溶菌酶、银纳米颗粒涂层改性纤维、量子点改性纤维、PEG改性纤维的红外光谱中酰胺I带分峰图

Fig.1

Deconvolution of FT-IR amide I band of native lysozyme (a), silver nanoparticle coating-modified fibers (b), quantum dot-modified fibers (c), and PEG-modified fibers (d)

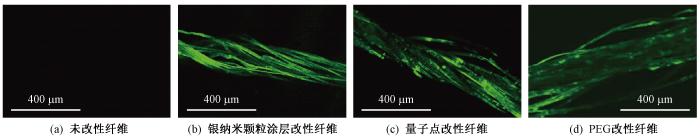

图2

图2

未改性纤维、银纳米颗粒涂层改性纤维、量子点改性纤维、PEG改性纤维的ThT染色激光共聚焦荧光显微镜照片

Fig.2

Laser confocal fluorescence photographs of ThT stained unmodified polyester fibers (a), silver nanoparticle coating-modified fibers (b), quantum dot-modified fibers (c), and PEG-modified fibers (d)

2.2 银纳米颗粒涂层改性纤维与织物性能分析

2.2.1 形貌分析

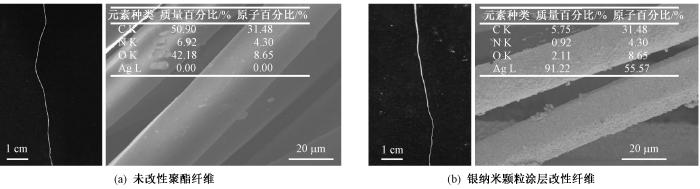

采用金属离子诱导蛋白质自组装的方法,在室温条件和水相体系中,将纤维浸泡到溶菌酶、银氨溶液和葡萄糖的混合溶液中孵育,即可在纤维表面构筑蛋白质焊接的银纳米颗粒涂层。

图3示出改性前后聚酯纤维的光学照片和扫描电镜照片。通过光学照片可以发现,改性后纤维的直径明显增加,且表面呈银白色。扫描电镜照片也显示,未改性纤维表面非常光滑,而改性后的纤维表面变粗糙,可观察到由溶菌酶和银纳米颗粒组成的连续均匀涂层。此外,由EDS能谱分析数据可知:未改性聚酯纤维的表面完全检测不到Ag元素存在;相反,改性后聚酯纤维表面中C、N、O元素含量较低(约占总比例的9%),Ag元素含量高达91.22%,表明纤维表面的改性涂层主要由银纳米颗粒组成,蛋白质在其中起到焊接银纳米颗粒和提供与纤维表面稳定黏附的作用。

图3

图3

未改性聚酯纤维和银纳米颗粒涂层改性纤维的光学照片、扫描电镜照片以及能谱分析数据

Fig.3

Photographs, SEM images and EDS data of unmodified polyester fibers (a) and silver nanoparticle coating-modified fibers (b)

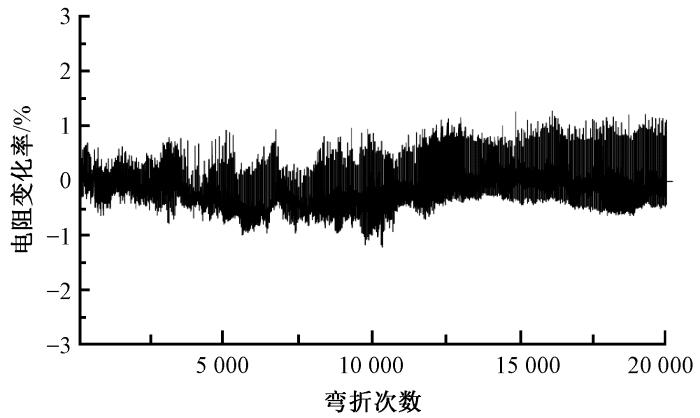

2.2.2 涂层稳定性及导电性能分析

利用胶带撕拉和弯折实验表征了功能涂层在纤维表面的黏附稳定性,结果如图4所示。可以看出,涂层抵抗胶带撕拉次数与溶菌酶质量浓度有关。溶菌酶质量浓度为0.01、0.02、0.03、0.04、0.05 mg/mL时,涂层分别可抵抗11、37、23、13、5次3M胶带撕拉。

图4

图4

银纳米颗粒涂层改性聚酯纤维的抗撕拉次数

Fig.4

Number of tear resistance tests conducted on silver nanoparticle coating-modified fibers

图5

图5

溶菌酶质量浓度为0.02、0.01和0.05 mg/mL时制备的银纳米颗粒涂层改性纤维的扫描电镜照片

Fig.5

SEM images of silver nanoparticle coating-modified fibers prepared at lysozyme concentration of 0.02 mg/mL, 0.01 mg/mL and 0.05 mg/mL

图6

图6

弯折次数对银纳米颗粒涂层改性纤维电阻的影响

Fig.6

Influence of bending cycles on electrical resistance of silver nanoparticle coating-modified fiber

2.2.3 抗菌性分析

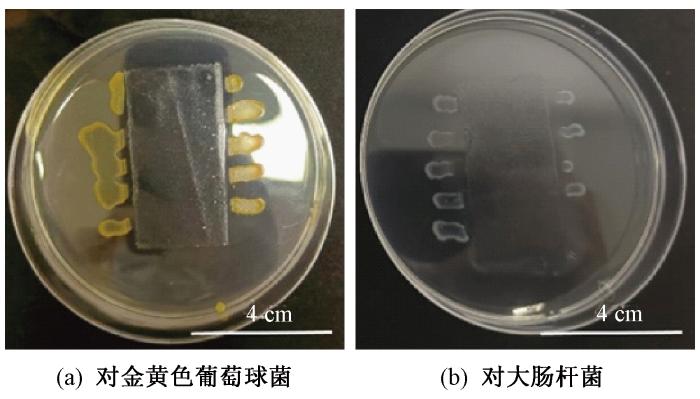

图7示出银纳米颗粒涂层改性织物对金黄色葡萄球菌和大肠杆菌的抗菌效果照片。从中可清晰地观察到在银纳米颗粒涂层改性织物边缘形成了透明的抑菌带。这表明银纳米颗粒涂层成功地抑制了金黄色葡萄球菌和大肠杆菌的生长。

图7

图7

银纳米颗粒涂层改性织物对金黄色葡萄球菌和大肠杆菌的抗菌效果光学照片

Fig.7

Photographs of antibacterial effect of silver nanoparticle coating-modified fabrics on S.aureus(a) and E.coli(b)

通过计算得出改性织物对金黄色葡萄球菌和大肠杆菌的抑菌带平均宽度分别为1.17、3.15 mm。这些抑菌区域的形成可能是由于银纳米颗粒离子化形成的银离子能够从纤维扩散至细菌细胞膜内部杀死细菌[14],因此,银纳米颗粒涂层改性纤维不仅具有优异的导电性能,还对金黄色葡萄球菌和大肠杆菌生长具有明显的抑制效果,在抗菌导电织物方面具有较大的应用前景。

2.3 量子点改性纤维性能分析

2.3.1 量子点改性纤维形貌分析

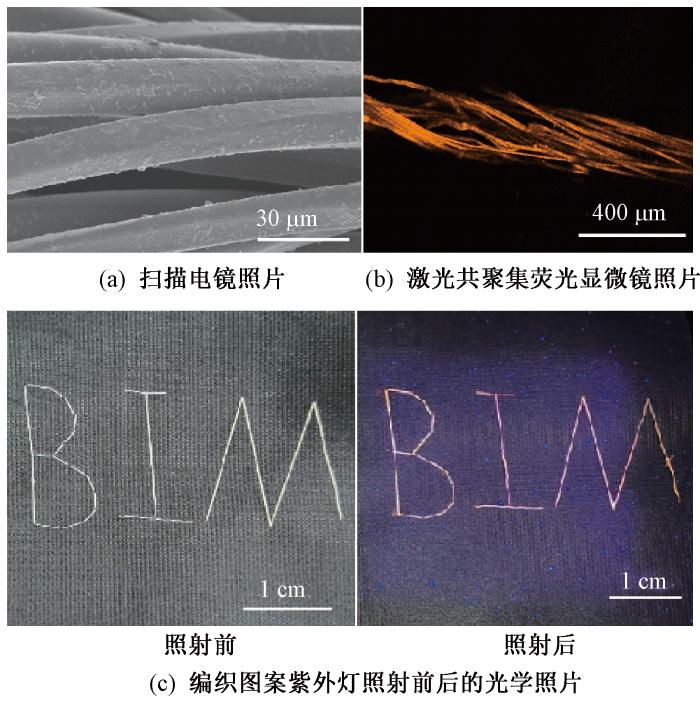

图8

图8

量子点改性纤维的扫描电镜照片、激光共聚焦荧光显微镜照片和编织图案紫外灯照射前后的光学照片

Fig.8

SEM image (a), laser confocal fluorescence microscope photograph(b) of quantum dot-modified fibers, and photographs of pattern woven with quantum dot modified fibers before and after exposure to UV irradiation (c)

2.3.2 量子点改性纤维荧光及稳定性分析

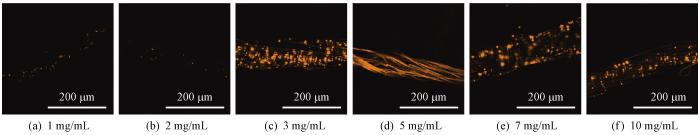

图9示出不同质量浓度溶菌酶溶液制备的改性纤维激光共聚焦荧光显微镜照片。可以看到,随着溶菌酶质量浓度的增加,纤维表面荧光呈现先增强后减弱的变化趋势,其中溶菌酶质量浓度为5 mg/mL时,所制备的改性纤维表面荧光强度最高且最连续。这是由于当溶菌酶质量浓度较低时,生成的蛋白质涂层较薄且包裹的量子点数量较少,所以纤维表面荧光强度低且不连续;而当溶菌酶质量浓度过高时,部分量子点会被蛋白质类淀粉样聚集产物包裹并沉积至反应容器底部而未成功附着于纤维表面,导致荧光强度降低。

图9

图9

不同质量浓度溶菌酶溶液制备的量子点改性纤维的激光共聚焦荧光显微镜照片

Fig.9

Fluorescence microscopy images of quantum dot-modified fibers prepared with various concentrations of lysozyme solutions

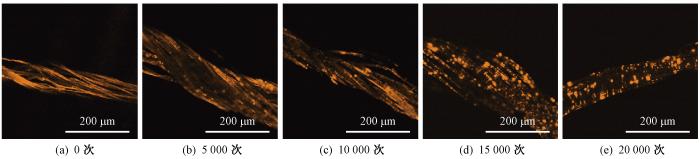

使用万能材料试验机固定改性纤维进行循环弯折测试,评估弯折次数对纤维荧光性能的影响,结果如图10所示。可以看出:随着弯折次数的增加,纤维表面的荧光强度几乎保持不变,但是量子点的分布逐渐变得不连续;10 000次循环以内量子点改性涂层能够稳定黏附在纤维表面,超过10 000次后涂层稳定性降低,荧光变得不连续。

图10

图10

不同弯折次数下量子点改性纤维的激光共聚焦荧光显微镜照片

Fig.10

Fluorescence microscope images of quantum dot-modified fibers under different bending cycles.

(a)0 cycle; (b)5 000 cyles; (c)10 000 cycles; (d)15 000 cycles; (e)20 000 cycles

2.4 PEG改性织物性能分析

2.4.1 滴水浸湿时间分析

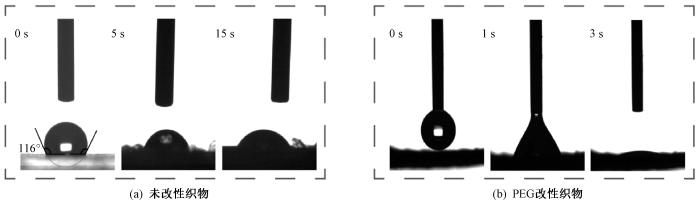

PEG具有良好的水溶性,常被用于提高材料的亲水性能。图11(a)示出未改性织物表面水滴浸湿过程中不同时间点的接触角照片。可以看出:在0 s时,织物表面水的接触角为116°,说明未改性聚酯织物具有一定的疏水性,但由于织物内部纤维之间存在大量间隙,所以随着时间延长,可观察到水滴能够缓慢浸湿到织物内部。

图11

图11

未改性织物和PEG改性织物表面水滴浸湿过程中不同时间点的接触角照片

Fig.11

Images showing contact angles at various time intervals during wetting process of unmodified fabric (a) and PEG modified fabric (b)

图11(b)示出2 mg/mL溶菌酶-PEG偶联物制备的PEG改性织物表面水滴浸湿过程中不同时间点的接触角照片。可以看出,与未改性织物对比,水滴接触改性织物后迅速浸湿,在3 s时完全浸润,说明改性后的织物表面亲水性显著提升。

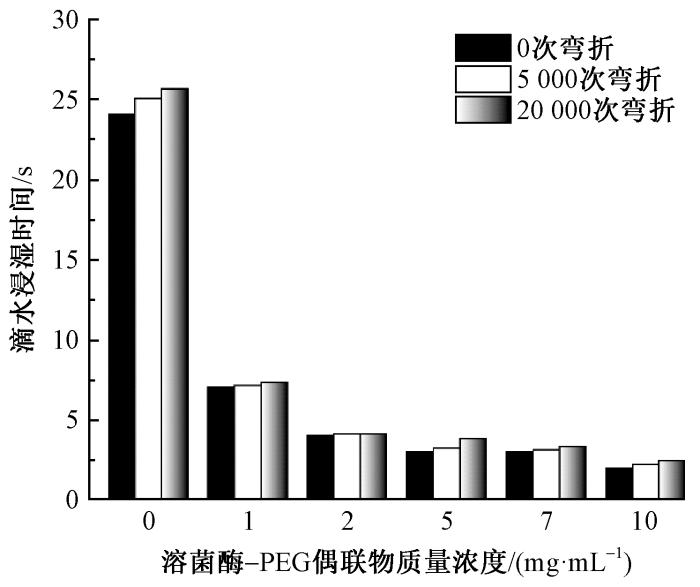

图12示出不同质量浓度溶菌酶-PEG偶联物制备的改性织物的滴水浸湿时间。可以看出,随着溶菌酶-PEG偶联物质量浓度的增加,改性织物的浸湿速度变快,相较于未改性织物,改性织物的滴水浸湿时间从24 s缩短至2.5 s。同时对改性织物弯折前后的滴水浸湿时间进行对比发现,经过5 000次和20 000次弯折后,改性织物的滴水浸湿时间变化较小,说明改性涂层具有良好的稳定性。

图12

图12

不同质量浓度溶菌酶-PEG偶联物制备的改性织物在不同弯折次数下的滴水浸湿时间

Fig.12

Wetting time of modified fabrics prepared with various concentrations of lysozyme-PEG solutions under different bending cycles

2.4.2 透湿率分析

图13

图13

不同质量浓度溶菌酶-PEG制备的改性织物在不同弯折次数下的透湿率

Fig.13

Moisture permeability of modified fabrics prepared with different concentrations of lysozyme-PEG solutions under different bending cycles

3 结论

本文基于溶菌酶类淀粉样聚集在聚酯纤维的表面成功构筑了厚度均匀、具有高界面黏附特性的功能涂层。根据功能物质的不同,分别制备了银纳米颗粒涂层改性纤维及织物、量子点改性纤维和聚乙二醇改性纤维及织物,主要得到如下结论。

1)银纳米颗粒涂层改性纤维具有优异的导电性能,1 cm纤维的电阻仅为1.39 Ω,涂层可抵抗胶带37次撕拉,经20 000次弯折后其电阻不会发生明显变化。银纳米颗粒使改性织物对金黄色葡萄球菌和大肠杆菌的生长具有明显的抑制效果。

2)量子点改性纤维在紫外光照射下发荧光且稳定性较好,经过10 000次弯折测试后其荧光强度不会发生明显衰减。

3)聚乙二醇接枝溶菌酶涂层显著提升了织物的亲水性能,改性织物的滴水浸湿时间由24 s缩短至2.5 s,透湿率由4 500 g/(m2·d)提高至5 800 g/(m2·d),改性层稳定可抵抗至少20 000次弯折。

基于蛋白质类淀粉聚集的纤维表面功能化策略简单高效、绿色环保且适用于各种功能纤维的制备,弥补了目前聚合物纤维表面功能化策略中改性工艺复杂、涂层稳定性差的不足,在构筑功能纤维和功能织物方面表现出巨大的潜力。

参考文献

柔性力感知电子织物的制备及其人体运动监测系统构建

[J].

Preparation of flexible force-sensing electronic textiles and construction of human motion monitoring system

[J].

适老化智能可穿戴设计研究进展及发展趋势

[J].

Progress and trends in application of wearable technology for elderly population

[J].

Fabrication techniques and sensing mechanisms of textile-based strain sensors: from spatial 1D and 2D perspectives

[J].

Investigation on multifunctional modification of cotton fabrics for salt-free dyeing, resisting crease and inhibiting bacteria

[J].

Composites based on polymeric blends reinforced with TiO2 modified aramid fibers

[J].

Friction and wear behaviors of surface-modified carbon fabric/epoxy resin composites

[J].

Amyloid fibril aggregation: an insight into the underwater adhesion of barnacle cement

[J].

DOI:S0006-291X(17)31721-7

PMID:28865959

[本文引用: 1]

Barnacles robustly adhere themselves to diverse submarine substrates through a proteinaceous complex termed the "barnacle cement". Previous studies have indicated that certain peptides derived from some barnacle cement proteins can self-assemble into amyloid fibrils. In this study, we assessed the self-assembly behavior of a full-length 19 kDa cement protein from Balanus albicostatus (Balcp19k) in different buffers. Results of Thioflavin T binding assay, transmission electron microscopy, and Fourier transform infrared spectroscopy suggested that the bacterial recombinant Balcp19k was able to aggregate into typical amyloid fibrils. The time required for the self-assembly process was close to that required for the complete curing of barnacle cement complex. Moreover, the solubility of Balcp19k amyloid deposits in guanidine hydrochloride and urea was same as that of the cured cement. These results indicated the inherent self-assembling nature of Balcp19k, implying that the amyloid fibril formation plays a critical role in barnacle cement curing procedure and its insolubility. Our results should be conducive to understanding barnacle underwater adhesion mechanisms and have implications in the development of new-generation antifouling techniques and in the designing of novel wet adhesives for biomedical and technical applications.Copyright © 2017 Elsevier Inc. All rights reserved.

Conversion of the OmpF porin into a device to gather amyloids on the E. coli outer membrane

[J].

2D protein supramolecular nanofilm with exceptionally large area and emergent functions

[J].

Multiplex binding of amyloid-like protein nanofilm to different material surfaces

[J].

Preparation of conductive polyester fibers using continuous two-step plating silver materials

[J].

Large-area display textiles integrated with functional systems

[J].

Amyloid-like rapid surface modification for antifouling and in-depth remineralization of dentine tubules to treat dental hypersensitivity

[J].

Antibacterial activity and characteristics of silver nanoparticles biosynthesized from carduus crispus

[J].

DOI:10.1038/s41598-021-00520-2

PMID:34702916

[本文引用: 1]

In recent years' synthesis of metal nanoparticle using plants has been extensively studied and recognized as a non-toxic and efficient method applicable in biomedical field. The aim of this study is to investigate the role of different parts of medical plant Carduus crispus on synthesizing silver nanoparticles and characterize the produced nanoparticle. Our study showed that silver nanoparticles (AgNP) synthesized via whole plant extract exhibited a blue shift in absorption spectra with increased optical density, which correlates to a high yield and small size. Also, the results of zeta potential, X-ray diffraction, photon cross-correlation spectroscopy analysis showed the surface charge of - 54.29 ± 4.96 mV (AgNP-S), - 42.64 ± 3.762 mV (AgNP-F), - 46.02 ± 4.17 mV (AgNP-W), the crystallite size of 36 nm (AgNP-S), 13 nm (AgNP-F), 14 nm (AgNP-W) with face-centered cubic structure and average grain sizes of 145.1 nm, 22.5 nm and 99.6 nm. Another important characteristic, such as elemental composition and constituent capping agent has been determined by energy-dispersive X-ray spectroscopy and Fourier transform infrared. The silver nanoparticles were composed of ~ 80% Ag, ~ 15% K, and ~ 7.5% Ca (or ~ 2.8% P) elements. Moreover, the results of the FTIR measurement suggested that the distinct functional groups present in both AgNP-S and AgNP-F were found in AgNP-W. The atomic force microscopy analysis revealed that AgNP-S, AgNP-F and AgNP-W had sizes of 131 nm, 33 nm and 70 nm respectively. In addition, the biosynthesized silver nanoparticles were evaluated for their cytotoxicity and antibacterial activity. At 17 µg/ml concentration, AgNP-S, AgNP-F and AgNP-W showed very low toxicity on HepG2 cell line but also high antibacterial activity. The silver nanoparticles showed antibacterial activity on both gram-negative bacterium Escherichia coli (5.5 ± 0.2 mm to 6.5 ± 0.3 mm) and gram-positive bacterium Micrococcus luteus (7 ± 0.4 mm to 7.7 ± 0.5 mm). Our study is meaningful as a first observation indicating the possibility of using special plant organs to control the characteristics of nanoparticles.© 2021. The Author(s).

京公网安备11010502044800号

京公网安备11010502044800号