随着工业的快速发展,食品、印染、皮革、石油化工、船舶等众多行业产生了大量的含油废水,这不仅影响着生态环境,还影响着人类的身体健康[1]。根据油和水的结合程度,可将油水混合物分为浮油、分散油、乳化油和溶解油[2]。乳化油可稳定分散至水中,传统的单润湿性分离材料难以对其进行油水分离[3]。分离乳化油的第1步就是破乳,传统的破乳方法包括热化学破乳法、电化学破乳法等[4],存在环境污染、能耗高、操作复杂、产品质量下降等缺点,因此,寻找更加高效、环保、经济的新型破乳方法是当前乳化油分离领域的重要研究方向之一[5]。研究者利用润湿性的不同[6],制备出可产生内驱力的分离材料[7-8],从而使乳化油发生破乳反应[9]。这种具有多种润湿性的分离材料也被称为非对称润湿性膜(Janus膜)[10-11],可针对乳化油进行油水分离[12]。

目前,制备Janus膜的方法有不对称修饰和层层自组装。通过简单的原位固定和单面改性方法可成功制备具有不对称润湿性和强抗菌活性的Janus纤维素膜(JCM)[13],其一侧具有超疏水特性,另一侧具有超亲水特性,在无外加能量的条件下,对各种水包油和油包水乳液均表现出优异的分离性能。连续静电纺丝或者同轴静电纺丝是层层自组装制备Janus分离膜常用的方法[14]。Cheng等[15]通过连续静电纺丝的方式制备了聚偏氟乙烯(PVDF)和醋酸纤维素(CA)膜,结合碱处理,开发了一种在空气、水或柴油环境中具有不对称润湿性的脱乙酰醋酸纤维素/聚偏氟乙烯(dCA/PVDF)Janus纳米纤维膜。在柴油/水乳化液分离过程中,超亲水的dCA层能够捕获乳化水,增强Janus膜的破乳能力;而超疏水的PVDF层起到了隔水作用,取得了显著的油水分离效果。

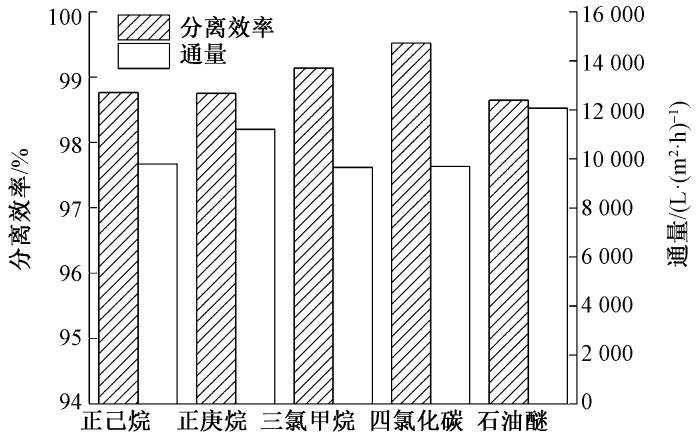

本文以木浆为原料,以氯化锂/N,N-二甲基乙酰胺为溶剂,采用静电纺丝技术,调控纺丝电压、纺丝速率、纺丝时间等关键参数制备纤维素纳米纤维膜;以纤维素纳米纤维膜和聚丙烯熔喷布为基材,利用二者亲疏水性的差异,结合热压工艺,构筑了具有Janus结构的纤维素纳米纤维/聚丙烯熔喷布复合膜,系统分析并评价了复合膜对乳化油的油水分离性能,这对高性能乳化油分离膜的发展具有一定的参考。

1 实验部分

1.1 实验材料

阔叶木浆板,亚太森博(山东)浆纸有限公司;N,N-二甲基乙酰胺(DMAC)、乙醇、石油醚,天津市江天化工技术股份有限公司;氯化锂,天津希恩思奥普德科技有限公司;聚丙烯熔喷布(面密度分别为20、30和40 g/m2),天津泰达洁净有限公司;吐温80,凯玛特(天津)化工科技有限公司;正己烷、四氯化碳,上海麦克林生化科技股份有限公司;正庚烷,山东艾纳生物科技有限公司;三氯甲烷,天津渤化化学试剂有限公司。

1.2 纤维素纳米纤维膜的制备

首先将阔叶木浆板剪成小份,再通过高速粉碎机将阔叶木浆板打成纤维状,并在80 ℃的真空烘干机中干燥至少8 h;分别称取一定量的上述纤维和DMAC放置于玻璃瓶中,二者质量分数为3%,在150 ℃、1 000 r/min的条件下,用磁力搅拌器搅拌150 min;然后加入氯化锂,温度调至120 ℃,搅拌30 min,当纤维素溶解为乳白状液体时,关闭加热。在1 000 r/min的条件下搅拌8 h以上,得到透明、黏稠状的纤维素纺丝液。

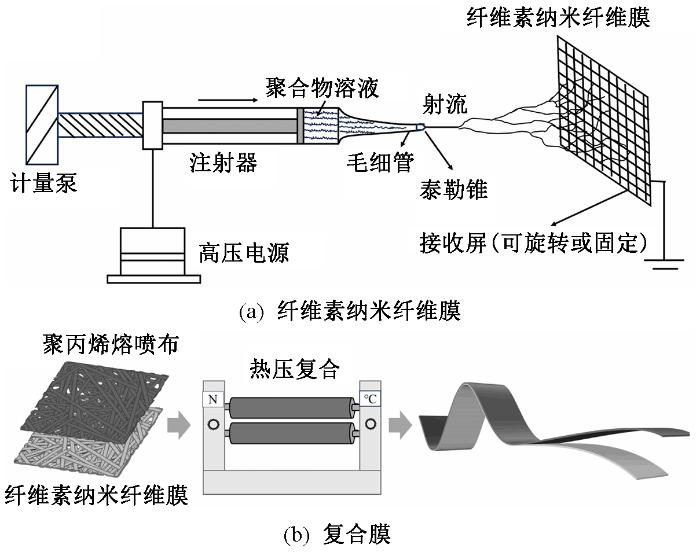

以配制的纤维素纺丝液为原料,以定制镂空金属转笼为收集器进行静电纺丝,接收距离设置为20 cm,通过调控纺丝电压、纺丝速率、纺丝时间等参数制备一系列纤维素纳米纤维膜。纺丝结束后,拆除金属网,连同金属网放置于乙醇溶液中,浸泡至少30 min。在60 ℃烘箱中干燥60 min,得到纤维素纳米纤维膜,制备工艺流程如图1(a)所示。

图1

图1

纤维素纳米纤维膜和复合膜的制备工艺流程

Fig.1

Preparation process diagram of cellulose nanofiber membrane (a) and composite membrane (b)

1.3 复合膜的制备

将商业化的聚丙烯熔喷布覆盖到纤维素纳米纤维膜上,结合热压工艺,构建Janus结构,通过调控聚丙烯熔喷布的面密度、热压温度、热压压力等条件制备纤维素纳米纤维/聚丙烯熔喷布复合膜,制备工艺流程如图1(b)所示。

1.4 测试与表征

1.4.1 形貌观察

采用JSM-IT300LV型扫描电子显微镜(SEM)观察纤维膜样品的形貌,测试时需将样品裁剪为3 mm2左右的小块粘贴在导电胶布上,喷金处理后在10 kV条件下观察。

1.4.2 接触角测试

采用Kruss K100接触角/表面张力测量仪测试样品的接触角。将样品用双面胶黏在载玻片上,再把载玻片放到载物台的高分辨率相机镜头下方进行测试。设置滴液量为5 μL,视频录制时间为1 min。

1.4.3 孔径测试

采用Porolux 1000型毛细流孔径分析仪测试样品的孔径。将待测样品剪成直径为2 cm的圆片,将其浸入Porefil 浸润液中浸润并充分浸渍2 min左右,取出样品放置在毛细流孔径分析仪的测量平台上进行测试。

1.4.4 拉普拉斯力测试

首先测试不同液体的表面张力以及不同液体与膜表面的接触角,然后按照下式计算由液面弯曲的曲率产生的拉普拉斯力:

式中:P为拉普拉斯力,Pa;γ为液体的表面张力,N/m;θ为液体与膜表面的接触角,(°);R为半径,m。

1.4.5 分离效率测试

用乳化油将分离膜充分润湿后,利用总有机碳分析仪(TOC)分别测试初始乳液和分离后滤液中油分的含量,通过初始乳液和分离滤液的油分含量比得到分离效率,计算公式为

式中:R为乳液分离效率,%;C1为乳液中的油分含量,mL/L;C2为滤液中的油分含量,mL/L。

1.4.6 通量测试

在0.1 MPa下将复合膜预压30 min,润湿后,开始倒入液体,记录溶液完全渗透的时间,按照下式计算复合膜的分离通量:

式中:Fa为通量,L/(m2·h);V为液体体积,L;A为有效面积,m2;t为时间,h。

1.4.7 分离重复性测试

每次使用复合分离膜对油水乳液进行分离后,将复合膜取出烘干,重复进行复合膜分离效率和通量的测试。

2 结果与讨论

2.1 纤维素纳米纤维膜的性能分析

2.1.1 形貌分析

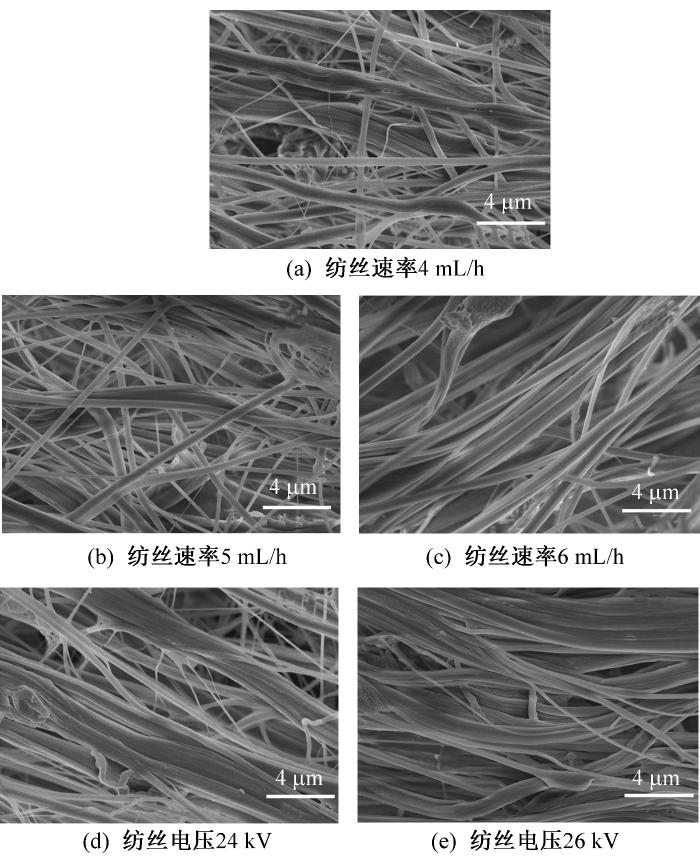

图2示出纤维素纳米纤维膜的SEM照片。可以看出:随着纺丝速率的增加,单位时间内电场中的纺丝液增多,电场内的电阻增加,单根纤维受到的牵伸力下降,致使纤维的直径增大;而随着纺丝电压的增加,单根纤维受到的牵伸力增加,纤维的直径减小。

图2

图2

不同参数下纤维素纳米纤维膜的SEM照片

Fig.2

SEM images of cellulose nanofiber membranes under different parameters.

(a) Spinning rate 4 mL/h; (b) Spinning rate 5 mL/h; (c) Spinning rate 6 mL/h; (d) Spinning voltage 24 kV; (e) Spinning voltage 26 kV

2.1.2 孔径和厚度分析

表1示出不同参数下纤维素纳米纤维膜的孔径和厚度。可知,在纺丝电压为25 kV、纺丝速率为5 mL/h的条件下,当纺丝时间从8 h增加到24 h时,纤维膜的孔径从7.212 μm减小到4.494 μm,厚度从0.145 mm升至0.425 mm。这是因为随着纺丝时间的增加,纤维膜单位体积内的纤维数增加,所以纤维膜的孔径减小和厚度增加。在纺丝时间为8 h、纺丝速率为5 mL/h的条件下,当纺丝电压从24 kV增加到26 kV时,纤维膜的平均孔径从6.694 μm减小到4.520 μm,厚度从0.166 mm减小到0.135 mm。这是因为纤维的细度增加,所以纤维膜的孔径和厚度降低。在纺丝时间为8 h、纺丝电压为25 kV的条件下,当纺丝速率从4 mL/h增加到6 mL/h时,纤维膜的孔径从4.099 μm增加到6.799 μm,厚度从0.126 mm增加到0.164 mm。这是因为纤维的细度降低,所以纤维膜的孔径和厚度增大。

表1 不同参数下纤维素纳米纤维膜的孔径和厚度

Tab.1

| 纺丝参数 | 纤维素纳米纤维膜特性 | |||

|---|---|---|---|---|

| 纺丝时 间/h | 纺丝电 压/kV | 纺丝速率/ (mL·h-1) | 孔径/ μm | 厚度/ mm |

| 8 | 25 | 5 | 7.212 | 0.145 |

| 16 | 25 | 5 | 5.029 | 0.281 |

| 24 | 25 | 5 | 4.494 | 0.425 |

| 8 | 24 | 5 | 6.694 | 0.166 |

| 8 | 26 | 5 | 4.520 | 0.135 |

| 8 | 25 | 4 | 4.099 | 0.126 |

| 8 | 25 | 6 | 6.799 | 0.164 |

2.1.3 润湿性分析

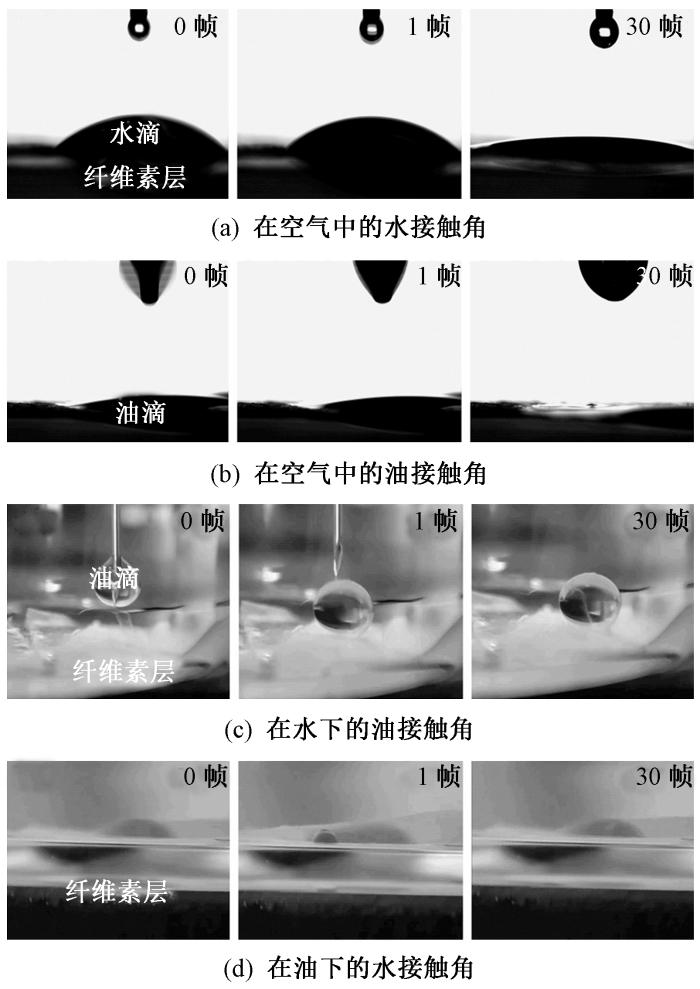

图3示出纤维素纳米纤维膜在空气中、水下以及油下的接触角测试结果。

图3

图3

纤维素纳米纤维膜的润湿性

Fig.3

Wettability of cellulose nanofiber membranes.

(a) Water contact angle in air; (b) Oil contact angle in air; (c) Oil contact angle in water; (d) Water contact angle in oil

由图3可看出:纤维素纳米纤维膜在空气中的水接触角和油接触角都小于90°;在水下的油接触角大于90°;在油下的水接触角小于90°。可见,纤维素纳米纤维膜在空气中表现出亲水性和亲油性(两亲性),在水下表现出疏油性,在油下表现出亲水性,但润湿时间有所增加,说明相较于空气介质中纤维素纳米纤维膜的亲水性有所降低。

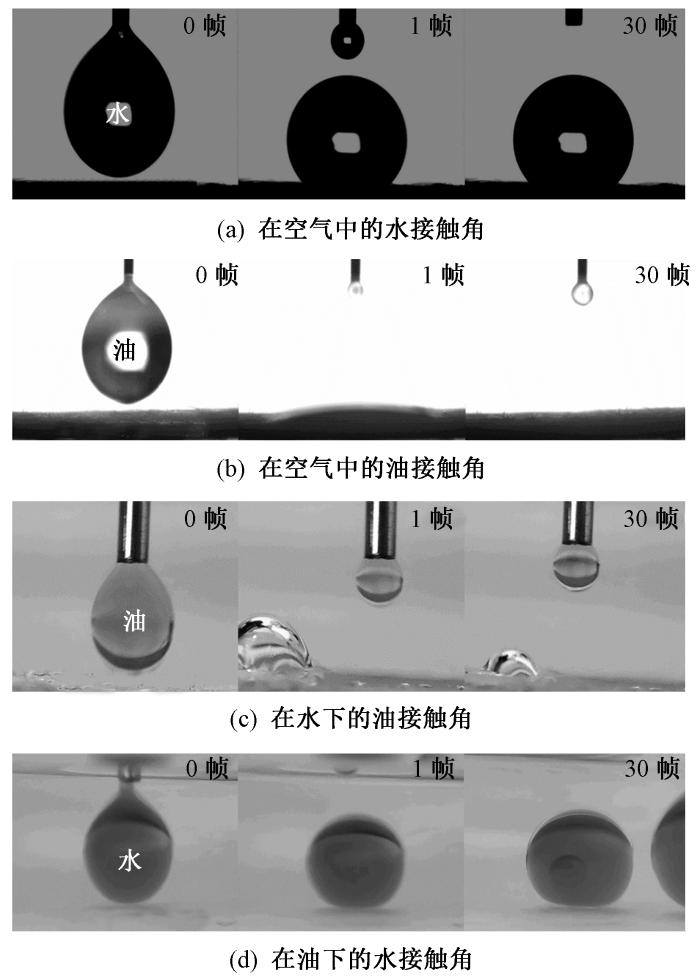

图4示出聚丙烯熔喷布在空气中、水下以及油下的接触角测试结果。可以看出:聚丙烯熔喷布在空气中的水接触角大于90°,油接触角小于90°;在油下的水接触角大于90°;在水下的油接触角小于90°。这说明聚丙烯熔喷布在空气中表现出疏水亲油,在油下表现出疏水性,在水下表现出亲油性。纤维素和聚丙烯材料在不同介质中的润湿性不同,可以用来制备Janus分离膜。

图4

图4

聚丙烯熔喷布的润湿性

Fig.4

Wettability of polypropylene meltblown nonwovens.

(a) Water contact angle in air; (b) Oil contact angle in air; (c) Oil contact angle in water; (d) Water contact angle in oil

2.2 复合膜的性能分析

2.2.1 孔径分析

复合膜的孔径与熔喷布的面密度、热压温度和压力密切相关。不同参数下复合膜的孔径如表2所示。可见,随着聚丙烯熔喷布面密度的增加,复合膜的孔径逐渐减小。在热压温度为130 ℃、热压压力为30 N的条件下,当聚丙烯熔喷布的面密度从20 g/m2增大到30、40 g/m2时,复合膜的孔径从1.178 μm减小至0.826、0.513 μm。在熔喷布面密度为30 g/m2、热压压力为30 N的条件下,当热压温度从110 ℃升高到150 ℃时,复合膜的孔径从1.360 μm减小到0.394 μm。这是因为热压温度增加,聚丙烯熔喷布中纤维熔融增加,聚丙烯纤维之间发生粘连,复合膜的孔径减小。在熔喷布面密度为30 g/m2、热压温度为120 ℃的条件下,当热压压力从10 N增加到50 N时,复合膜的孔径从1.330 μm减小到0.573 μm。这是因为随着热压压力的增加,纤维素纳米纤维膜和聚丙烯熔喷布受到挤压的效果增强,纤维膜内部孔隙减小,复合膜的孔径减小。

表2 不同参数下复合膜的孔径

Tab.2

| 工艺参数 | 复合膜的 孔径/μm | ||

|---|---|---|---|

| 熔喷布面密度/ (g·m-2) | 热压温 度/℃ | 热压压 力/N | |

| 20 | 130 | 30 | 1.178 |

| 30 | 130 | 30 | 0.826 |

| 40 | 130 | 30 | 0.513 |

| 30 | 110 | 30 | 1.360 |

| 30 | 120 | 30 | 1.165 |

| 30 | 140 | 30 | 0.614 |

| 30 | 150 | 30 | 0.394 |

| 30 | 120 | 10 | 1.330 |

| 30 | 120 | 20 | 0.983 |

| 30 | 120 | 40 | 0.709 |

| 30 | 120 | 50 | 0.573 |

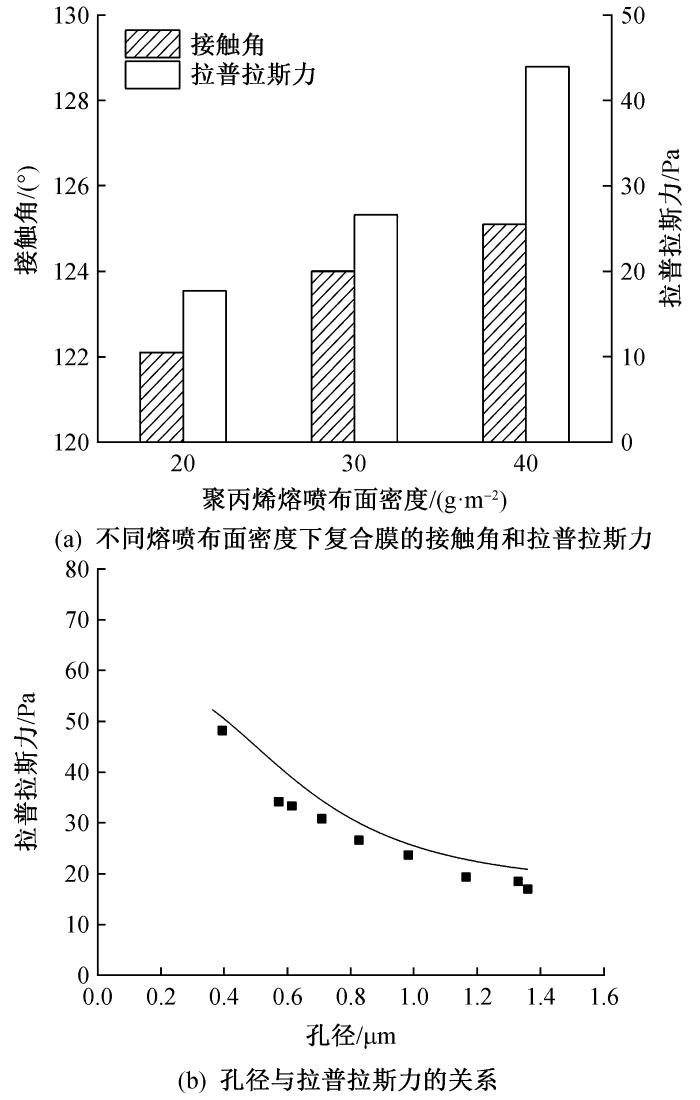

2.2.2 接触角和拉普拉斯力分析

图5

图5

不同参数下复合膜的拉普拉斯力

Fig.5

Laplace force of composite membranes under different parameters.

(a) Contact angle and Laplace force of composite membranes with different meltblown fabric density; (b) Relationship between pore size and Laplace force

由图5还可知,孔径与拉普拉斯力呈反比,当孔径越小时,拉普拉斯力越大,破乳能力也越强。

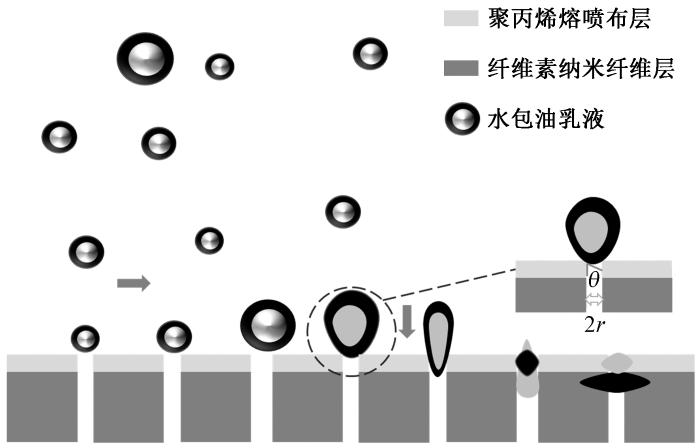

2.2.3 分离性能分析

图6

拉普拉斯力是影响乳化油破乳的主要指标,直接反映了复合膜的分离效率和通量。拉普拉斯力越大,复合膜的分离效率越大,但突破所需要的能量也就越多,通量就会减小。具有微纳米结构的复合膜拥有合适的厚度和孔径,最大程度降低了液滴突破所需要的能量,增大通量。不同参数下复合膜对正己烷/水油水混合物的分离效率和通量如表3所示。由表可知:在热压温度为130 ℃、热压压力为30 N的条件下,当聚丙烯熔喷布面密度增加时,接触角增加,拉普拉斯力增加,复合膜的分离效率从95.8%提升至98.9%,通量从17 956.5 L/(m2·h)降低至8 726.1 L/(m2·h);在固定其它参数不变的条件下,当热压温度或热压压力提高时,复合膜的孔径减小,分离效率增加,但通量降低。当熔喷布面密度为30 g/m2、热压温度为130 ℃、热压压力为30 N时,复合膜的分离效率和通量较为均衡,分离效率为98.8%,通量为9 798.8 L/(m2·h)。

表3 不同参数下复合膜的分离效率和通量

Tab.3

| 工艺参数 | 复合膜性能 | |||

|---|---|---|---|---|

| 熔喷布面密 度/(g·m-2) | 热压温 度/℃ | 热压压 力/N | 分离效 率/% | 通量/ (L·(m2·h)-1) |

| 20 | 130 | 30 | 95.8 | 17 956.5 |

| 30 | 130 | 30 | 98.8 | 9 798.8 |

| 40 | 130 | 30 | 98.9 | 8 726.1 |

| 30 | 110 | 30 | 98.0 | 15 788.1 |

| 30 | 120 | 30 | 98.4 | 12 615.1 |

| 30 | 140 | 30 | 99.1 | 5 183.1 |

| 30 | 150 | 30 | 99.3 | 2 105.1 |

| 30 | 120 | 10 | 96.8 | 33 873.7 |

| 30 | 120 | 20 | 97.9 | 22 962.5 |

| 30 | 120 | 40 | 98.9 | 7 105.1 |

| 30 | 120 | 50 | 99.3 | 5 183.1 |

图7

图7

乳化油的分离效果

Fig.7

Separation effect of emulsified oil.

(a) Optical pictures before and after separation; (b) Particle size distribution before and after separation

2.2.4 重复性能分析

图8示出复合膜在不同重复次数下的分离效率和通量。可以看出,随着重复次数的增加,可能存在乳液聚集、复合膜烘干不充分等环境因素的影响,分离膜的分离效率和通量都在一定范围内波动。当复合膜经10次重复使用后,其分离效率为98%,通量为9 444.5 L/(m2·h),分离效果依然显著,这说明分离膜具有优异的重复使用性能。

图8

图8

复合膜在不同重复次数下的分离效率和通量

Fig.8

Separation efficiency and flux of composite membranes at different number of repetitions

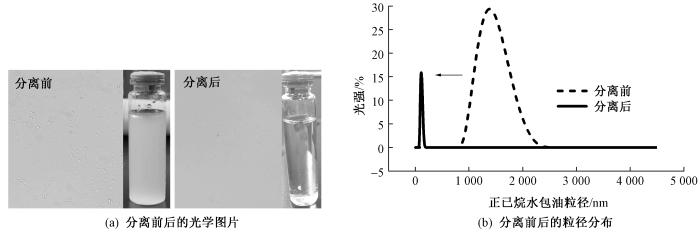

2.2.5 广泛适用性分析

复合膜对正己烷、正庚烷、三氯甲烷、四氯化碳和石油醚5种乳化油的分离效果如图9所示。可以看出:复合膜对正己烷乳化油的分离效率为98.8%,通量为9 798.9 L/(m2·h);复合膜对正庚烷乳化油的分离效率为98.75%,通量为11 210.1 L/(m2·h);复合膜对三氯甲烷乳化油的分离效率为99.14%,通量为9 700.6 L/(m2·h);复合膜对四氯化碳乳化油的分离效率为99.52%,通量为9 649.6 L/(m2·h);复合膜对石油醚乳化油的分离效率为98.65%,通量为12 068.3 L/(m2·h)。

图9

图9

复合膜分离不同乳化油的分离效率和通量

Fig.9

Separation efficiency and flux of different emulsified oils separated by composite membranes

3 结论

本文采用静电纺丝技术制备了纤维素纳米纤维膜,将其与聚丙烯熔喷布热压复合,制备了非对称润湿性纤维素纳米纤维/聚丙烯熔喷布复合膜,研究了其对乳化油的油水分离性能,得到如下结论。

1)当纺丝时间为16 h、纺丝电压为25 kV、纺丝速率为5 mL/h,纤维素纳米纤维膜性能最佳,平均孔径为5.029 μm,厚度为0.281 mm。纤维素纳米纤维膜在空气中表现出两亲性,在水下表现出疏油性,在油下表现出亲水性。

2)当熔喷布面密度为30 g/m2、热压温度为130 ℃、热压压力为30 N时,复合膜的分离效率和通量最均衡,分别为98.8%和9 798.9 L/(m2·h)。

3)复合膜具有优异的重复使用性能,经10次使用后,其分离效率为98%,通量为9 444.5 L/(m2·h),分离效果依然显著。复合膜对常见的5种乳化油均具有显著分离效果。

参考文献

Oil/water separation techniques: a review of recent progresses and future directions

[J].

Janus膜的制备及其应用研究进展

[J].

DOI:10.11868/j.issn.1001-4381.2019.000530

[本文引用: 1]

膜材料是现代分离技术和能源开发及利用的基础材料。其中,Janus(罗马双面神)膜由于其两侧的形貌结构或化学组成具有不对称性,因此赋予Janus膜材料某些优于均相膜材料的独特性能。近年来,随着人们对Janus膜认识、研究的深入以及应用领域的拓展和需求的提升,Janus膜的设计、构筑及其在多领域中的应用研究受到材料科学家的广泛关注。基于此,本文对Janus膜的常见类型及制备方法进行综述,归纳并总结其在液体单向透过、油水分离及海水淡化等领域中的应用研究进展,最后,指出Janus膜在制备方法方面所面临的挑战,如不同应用领域所需要的膜厚不同,如何实现膜厚度的精确控制等,并对Janus膜在油水分离、空气中雾水手机等应用中的发展趋势进行展望。

Advances in the preparation and application of Janus membranes

[J].

Bioinspired oil-water separation approaches for oil spill clean-up and water purification

[J].

Designing novel superwetting surfaces for high-efficiency oil-water separation: design principles, opportunities, trends and challenges

[J].

Polymeric materials with switchable superwettability for controllable oil/water separation: a comprehensive review

[J].

Janus membranes with controllable asymmetric configurations for highly efficient separation of oil-in-water emulsions

[J].

Janus membranes: creating asymmetry for energy efficiency

[J].

Constructing environmental-friendly ″Oil-Diode″ janus membrane for oil/water separation

[J].

Porous Janus materials with unique asymmetries and functionality

[J].

Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: a new strategy beyond nature

[J].

DOI:10.1039/c4cs00220b

PMID:25311259

[本文引用: 1]

Oil spills and industrial organic pollutants have induced severe water pollution and threatened every species in the ecological system. To deal with oily water, special wettability stimulated materials have been developed over the past decade to separate oil-and-water mixtures. Basically, synergy between the surface chemical composition and surface topography are commonly known as the key factors to realize the opposite wettability to oils and water and dominate the selective wetting or absorption of oils/water. In this review, we mainly focus on the development of materials with either super-lyophobicity or super-lyophilicity properties in oil/water separation applications where they can be classified into four kinds as follows (in terms of the surface wettability of water and oils): (i) superhydrophobic and superoleophilic materials, (ii) superhydrophilic and under water superoleophobic materials, (iii) superhydrophilic and superoleophobic materials, and (iv) smart oil/water separation materials with switchable wettability. These materials have already been applied to the separation of oil-and-water mixtures: from simple oil/water layered mixtures to oil/water emulsions (including oil-in-water emulsions and water-in-oil emulsions), and from non-intelligent materials to intelligent materials. Moreover, they also exhibit high absorption capacity or separation efficiency and selectivity, simple and fast separation/absorption ability, excellent recyclability, economical efficiency and outstanding durability under harsh conditions. Then, related theories are proposed to understand the physical mechanisms that occur during the oil/water separation process. Finally, some challenges and promising breakthroughs in this field are also discussed. It is expected that special wettability stimulated oil/water separation materials can achieve industrial scale production and be put into use for oil spills and industrial oily wastewater treatment in the near future.

Coexistence of superhydrophilicity and superoleophobicity: theory, experiments and applications in oil/water separation

[J].

Oil/water separation with selective superantiwetting/superwetting surface materials

[J].

Facile preparation of an asymmetric wettability janus cellulose membrane for switchable emulsions' separation and antibacterial property

[J].

Advanced electrospun nanofibrous materials for efficient oil/water separation

[J].

Rational design of Janus nanofibrous membranes with novel under-oil superhydrophilic/superhydrophobic asymmetric wettability for water-in-diesel emulsion separation

[J].

京公网安备11010502044800号

京公网安备11010502044800号