皮肤作为保护机体器官和组织免受外界刺激的重要屏障,一旦受损便极易被外界病原微生物侵入引起炎症。为促进伤口愈合,须用适宜的材料来遮盖伤口,以防创面感染[1]。由纱布、棉垫、薄纱等组成的传统敷料是最早、最广泛使用的敷料,较易制备且原料来源广,但这类敷料常因通透性差,使得伤口长期处在密闭不透气的环境,从而造成伤口的恶化甚至引发感染;而结构类似纱网的敷料,对伤口的保护措施差,不能有效阻隔细菌侵入,在更换过程中易黏着伤口,造成二次损伤[2-3]。已有研究证实,选用生物相容、可降解材料制得的纳米纤维膜用作医用敷料,贴于创伤组织能达到迅速愈合伤口而不会引发感染的效用[4-5],这使得静电纺纳米纤维在创面修复、伤口止血、防细胞粘连、促皮肤组织愈合等领域具有广泛的应用前景[6-7]。

海藻酸钠(SA)是从海洋里的褐藻植物中提取到的一种天然多糖类高分子[8],不溶于乙醇、四氢呋喃、氯仿等有机溶液,易溶于水,但溶解度不高,具有药物制剂敷料所需的稳定性、可降解性和生物相容性等特性[9]。SA结构单元中含有较多的羟基和羧基[10],溶于水中非常低的浓度便开始凝胶化,分子链呈刚性和蠕虫状结构,因此溶液中含有的物质不足以提供足够的链缠结来形成纤维结构,故无论是在水溶液中还是在有机溶剂中,使用静电纺丝技术从纯SA溶液制备出连续且均匀的纳米纤维结构都显得尤为困难[11-12]。为获得含SA的纳米纤维,现有研究通常将其与其它聚合物通过物理混合或化学作用的方法进行制备[13]。聚环氧乙烷(PEO)是人工合成的无毒性且有较高水溶性的高分子材料,与SA共混可调节其阴离子间的排斥力,提高其链的柔韧性。此外,PEO分子链中的醚氧与SA的羟基之间可形成氢键,以增加聚合物链缠结使其能连续射流,形成形态和直径均匀的纳米纤维,提高可纺性[14-15]。聚乙烯吡咯烷酮(PVP)是安全无毒且易溶于水的生物相容性聚合物,研究中常用其混合其它材料以提升纺丝液的性质,主要作用是降低溶液表面张力、改善溶液黏稠度及提高纺丝效率[16]。

1 实验部分

1.1 实验材料与仪器

材料:海藻酸钠(SA,黏度为150 mPa·s),青岛明月海藻集团有限公司;聚环氧乙烷(PEO,分析纯,重均分子量为300 000),德国良制化学有限公司;无水氯化钙(CaCl2)、聚乙烯吡咯烷酮(PVP,K30型,重均分子量为44 000)、无水乙醇,均为分析纯,国药集团化学试剂有限公司;磷酸盐缓冲溶液(PBS,pH值为7.47),上海麦克林生化科技有限公司;去离子水,实验室供应。

图1

实验用其它设备:FA1004型电子分析天平,宁波市鄞州华丰电子仪器厂;HJ-6型磁力搅拌器,金坛区西城新瑞仪器厂;KQ2200B型超声波清洗机,昆山市超声波仪器有限公司;DHG-9030A型鼓风干燥箱、DZF-6020型真空干燥箱,上海一恒科技仪器有限公司;FE38型台式电导率仪,梅特勒托利多仪器有限公司;MC1000型日立高新磁控溅射器、S3400N型台式扫描电子显微镜,日立高新科技公司;SU8010型场发射扫描电子显微镜,日本日立公司;Spectrum Two型傅里叶变换红外光谱仪,日本PerkinElmer公司;HH-4型恒温水浴锅,力辰科技有限公司。

1.2 复合纳米纤维膜的制备

称取1.0 g的SA粉末置于49 g的去离子水中,放于磁力搅拌器中搅拌8 h后制得溶质质量分数为2.0%、体积为50 mL的SA水溶液。同样称取4.0 g 的PEO置于46 g的去离子水中,放于磁力搅拌器中搅拌8 h后制得溶质质量分数为8.0%、体积为50 mL 的PEO水溶液。将制得的SA溶液和PEO溶液分别按体积比为30∶70、40∶60、50∶50、60∶40、70∶30混合,制备成不同比例的纺丝液,分别搅拌4 h并置于超声波清洗机中脱泡。使用自制静电纺丝装置,调节纺丝过程中的纺丝电压、接收距离,以聚丙烯纺黏布为接收基布收集SA/PEO复合纳米纤维膜。在优化的SA与PEO体积比的基础上,分别加入 5%、10%、15%的PVP(PVP加入量为SA/PEO的总质量占比,下同),纺制成SA/PEO/PVP复合纳米纤维膜。纺丝实验在相对湿度为40%和温度为25 ℃的条件下进行。

1.3 复合纳米纤维膜的交联处理

将实验制备的SA/PEO/PVP纳米纤维膜裁剪成一定规格,分别置于CaCl2质量分数为3.0%的无水乙醇溶液中,在室温下密封交联反应不同的时间(0、2、4、8、12、24 h)。交联完成后取出试样,并用无水乙醇清洗表面多余的CaCl2,然后在室温下晾干(24 h),得到交联改性的SA/PEO/PVP复合纳米纤维膜。

1.4 测试与表征

1.4.1 表面形貌观察和直径测试

参照GB/T 16594—2008《微米级长度的扫描电镜测量方法通则》,采用台式扫描电子显微镜和场发射扫描电子显微镜对纳米纤维膜的微观形貌进行观察。通过 Nano Measurer 1.2软件在电镜照片中随机选取100根纤维进行测量,并计算平均直径及方差。

1.4.2 电导率测试

参照GB/T 11007—2008《电导率仪试验方法》,采用台式电导率仪测试纺丝液的电导率。

1.4.3 化学结构表征

参照GB/T 6040—2019《红外光谱分析方法通则》,采用傅里叶变换红外光谱仪测试纳米纤维膜的红外光谱图,扫描范围为4 000~400 cm-1。

1.4.4 吸液倍率和质量损失率测试

参照GB/T 1034—2008《塑料 吸水性的测定》,采用称取质量法测试纳米纤维膜的吸液倍率和质量损失率。首先将不同交联时间(0、2、4、8、12、24 h)下处理的样品裁剪成一定大小,记录其初始干态质量(m0)。然后放入100 mL的PBS缓冲溶液浸泡24 h,取出后使用蒸馏水冲洗3次,将滤纸置于试样表面以吸干其表面水分,并记录湿态质量(mw),真空干燥至恒态质量(md)。3次平行实验后,依据下式分别求得其平均吸液倍率(W)和质量损失率(S):

1.4.5 湿热稳定性测试

为模拟人体皮肤的湿热环境,将纳米纤维膜置于恒温水浴锅中,设置温度分别为25、40和70 ℃ 共3组实验,每组浸泡时间设为1 h和3 h。将交联干燥处理后的试样裁剪成3 cm × 3 cm,并记下此时试样的面密度M1;然后浸泡1 h后取出,用鼓风干燥箱烘干处理1 h,再记下试样的面密度M2;接着浸泡2 h后烘干,记下试样的面密度M3。通过计算试样浸泡前的面密度M1和浸泡1、3 h后的面密度M2、M3的变化,分析材料的湿热稳定性。测试参照ASTM D471-16a—2021《液体对橡胶性能影响的标准试验方法》进行。

2 结果与讨论

2.1 SA与PEO体积比对纤维形貌的影响

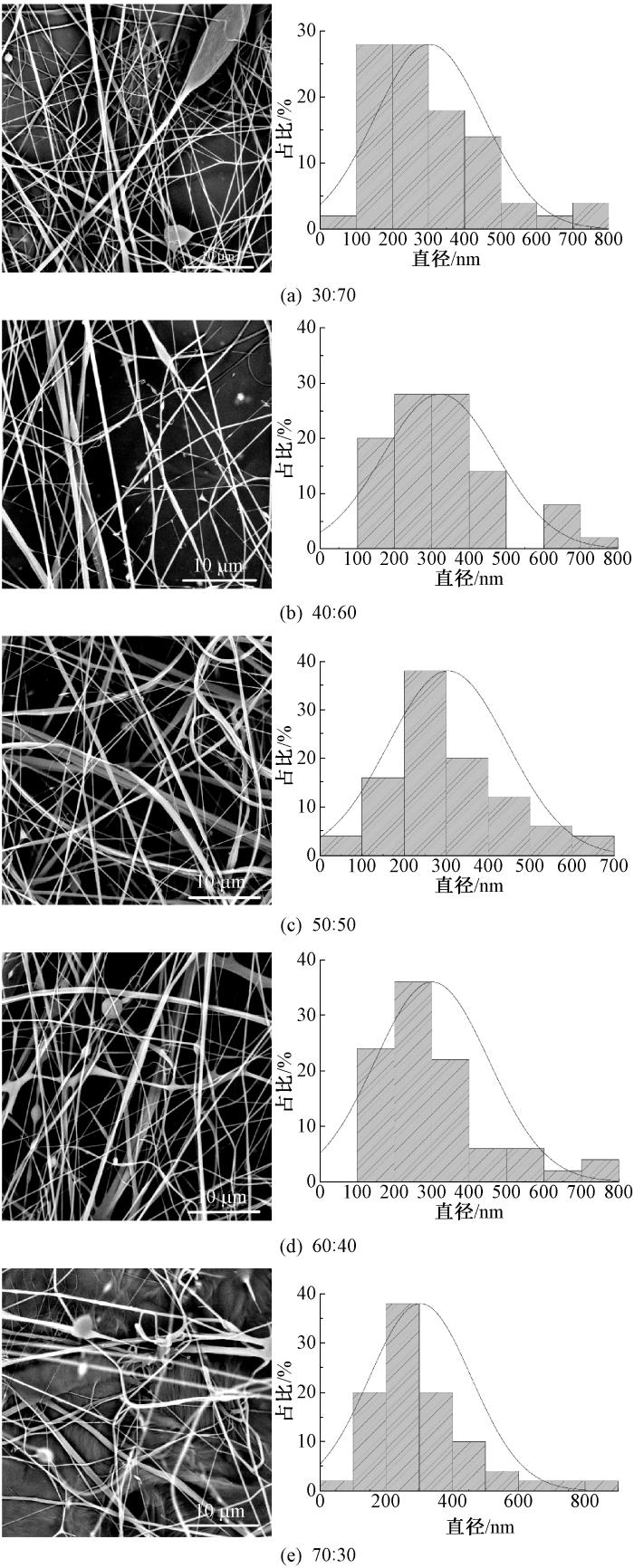

按照体积比为30∶70、40∶60、50∶50、60∶40、70∶30的SA溶液(质量分数为2.0%)和PEO溶液(质量分数为8.0%)配制成纺丝液,在纺丝电压为25 kV、纺丝距离为15 cm的条件下进行纺丝。观察不同比例的SA/PEO纳米纤维的表观形貌和纤维直径分布,结果如图2所示。可以看出:当SA与PEO体积比为30∶70时,纺丝过程相对不稳定,纤维出现了明显的珠串现象,且纤维直径分布不均;随着PEO比例逐渐降低,纤维中的珠串现象得到改善,当体积为50∶50时,纤维表面变得更加光滑,且纤维直径的均匀性明显提高,直方图中纤维直径的分布更为集中,表明此时的溶液配比更有利于形成质量更高的纳米纤维;当SA的比例超过50%,PEO含量降低时,纤维的产出量有所下降,纤维开始出现相互粘连的现象,直径分布也变得更加不均匀。这可能是由于SA含量的增加导致溶液的黏性增大,使得纤维较难被拉伸成细丝,从而影响了纤维的形成和质量。

图2

图2

SA与PEO溶液在不同体积比下制备的静电纺纳米纤维的SEM照片和直径分布图

Fig.2

SEM images and diameter distribution graphs of electrospun nanofibers prepared from SA/PEO solutions at different volume ratios

测得的纤维直径参数见表1。可以看出,不同比例下纤维的平均直径差异不大,其中相对来说,极差最小且直径分布较集中的是体积比为50∶50的SA/PEO纺丝液,此时制得的纳米纤维平均直径为300 nm,直径大小分布均匀,纤维成形形貌最佳。综上,形貌最佳的纺丝液为质量分数为2%的SA与质量分数为8%的PEO按体积比为50∶50配制,即SA与PEO的质量比为1∶4,因此优选此配比纺丝液进行后续实验探究。

表1 不同比例SA/PEO静电纺纳米纤维的直径分布参数

Tab.1

| SA与PEO体积比 | 平均直径/nm | 极差/μm | CV值/% |

|---|---|---|---|

| 30∶70 | 300 | 0.64 | 49.94 |

| 40∶60 | 320 | 0.67 | 47.39 |

| 50∶50 | 300 | 0.59 | 46.41 |

| 60∶40 | 300 | 0.62 | 50.64 |

| 70∶30 | 300 | 0.74 | 50.61 |

2.2 PVP对纺丝液和纤维膜性能的影响

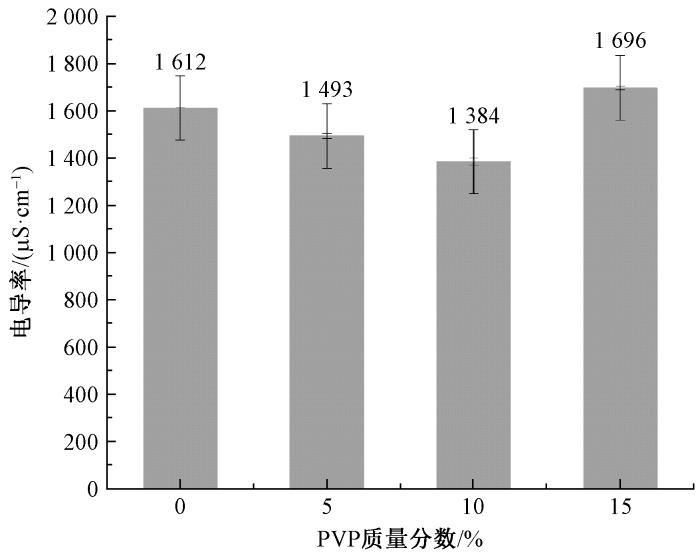

2.2.1 纺丝液电导率

由于 SA 是阴离子型聚电解质,其含量直接影响纺丝液的性质和成纤性能。在较低浓度时,SA水溶液便有很高的电导率,但由于溶液中有效成分过少,难以形成稳定的射流,因此不利于生成连续均匀的纳米纤维。随着SA含量的小幅增加,电导率与黏度同时上升,导致射流不稳定,形成的纤维粗细不一致[21]。为改善这一状况,加入PVP以提升纺丝液的静电纺丝性能,增强成纤性。

为探究PVP的最佳加入量,已确定SA与PEO的最佳质量比为1∶4,以此配制总溶质质量分数为4%的SA/PEO纺丝液(0.8%SA、3.2%PEO),分别加入占溶质质量分数为0%、5%、10%、15%的PVP进行实验,对比分析不同纺丝液的电导率变化,结果如图3所示。可以看出:随着PVP质量分数的增加,电导率呈现先降低后上升的趋势;当PVP质量分数为10%时,电导率降至最低值1 384 μS/cm。这是因为PVP作为非离子型聚合物,能够在适当比例时减少SA分子间的静电排斥,降低溶液电导率,促进稳定射流的形成;当PVP用量过高时,溶液黏度的增加及可能的复杂分子间相互作用,导致电导率再次上升。

图3

图3

PVP质量分数对纺丝液电导率的影响

Fig.3

Influence of PVP mass fraction on conductivity of spinning fluid

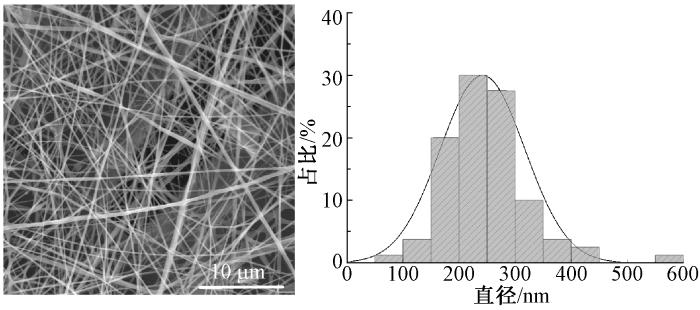

2.2.2 纤维形貌

在纺丝电压为25 kV、纺丝距离为15 cm的条件下,选择最佳配比(SA与PEO质量比为1∶4,SA/PEO总质量分数为4%,PVP质量分数为10%)制备SA/PEO/PVP纳米纤维,其形貌图及直径分布直方图见图4。观察可知,纺丝量有了明显提升,纤维表面光滑,串珠或珠粒的形成减少,成形状态良好。纤维直径分布图结果表明,将SA、PEO和PVP按比例混合制备的纤维直径分布较集中,平均直径为240 nm,95%的纤维直径分布在100~400 nm区间,其中在200~300 nm区间的纤维占57.5%。

图4

图4

最优工艺制备的SA/PEO/PVP复合纳米纤维的SEM照片和直径分布图

Fig.4

SEM image and diameter distribution of SA/PEO/PVP composite nanofibers prepared by optimal process

2.3 交联处理对纤维膜结构和性能的影响

2.3.1 交联后表面形貌

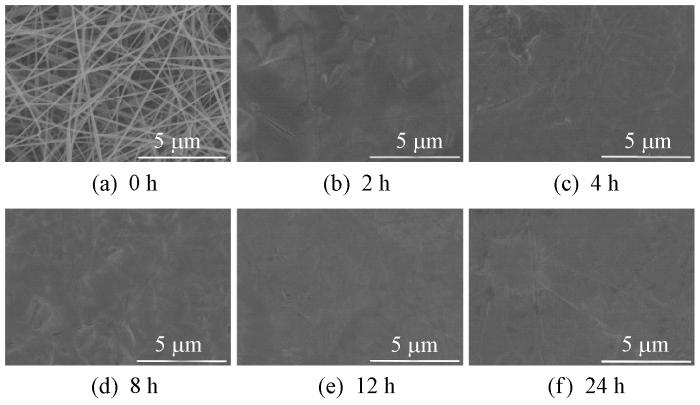

为增强SA/PEO/PVP纳米纤维膜的耐水性,选用CaCl2无水乙醇溶液对其进行交联改性处理,并观察了不同交联时间下纤维形貌的变化,如果如图5所示。

图5

图5

SA/PEO/PVP复合纳米纤维膜经不同时间CaCl2交联处理后的微观形貌

Fig.5

Microscopic morphology of SA/PEO/PVP composite nanofiber membranes after cross-linking treatment with CaCl2 for different durations

从图5可看出:在未交联的初始状态下,复合纳米纤维膜清晰地呈现出纤维结构及纤维间的孔隙;交联2 h后,纤维膜的孔隙已基本消失,纤维结构开始溶胀,且其连续性变得模糊;延长交联时间至4 h和8 h,纤维膜的表面出现了不平整的膜结构;当交联时间达到12 h和24 h,膜结构变得更加平滑和均匀。分析原因,Ca2+在纤维间的交联点数量增加,促使纤维融合并逐渐失去原有的纤维形态,随着交联时间的延长,纤维膜的溶胀和融合更为彻底,纤维结构逐步转化为连续且无孔的膜状结构,而交联密度的提高也加强了膜的连续性和均匀性。

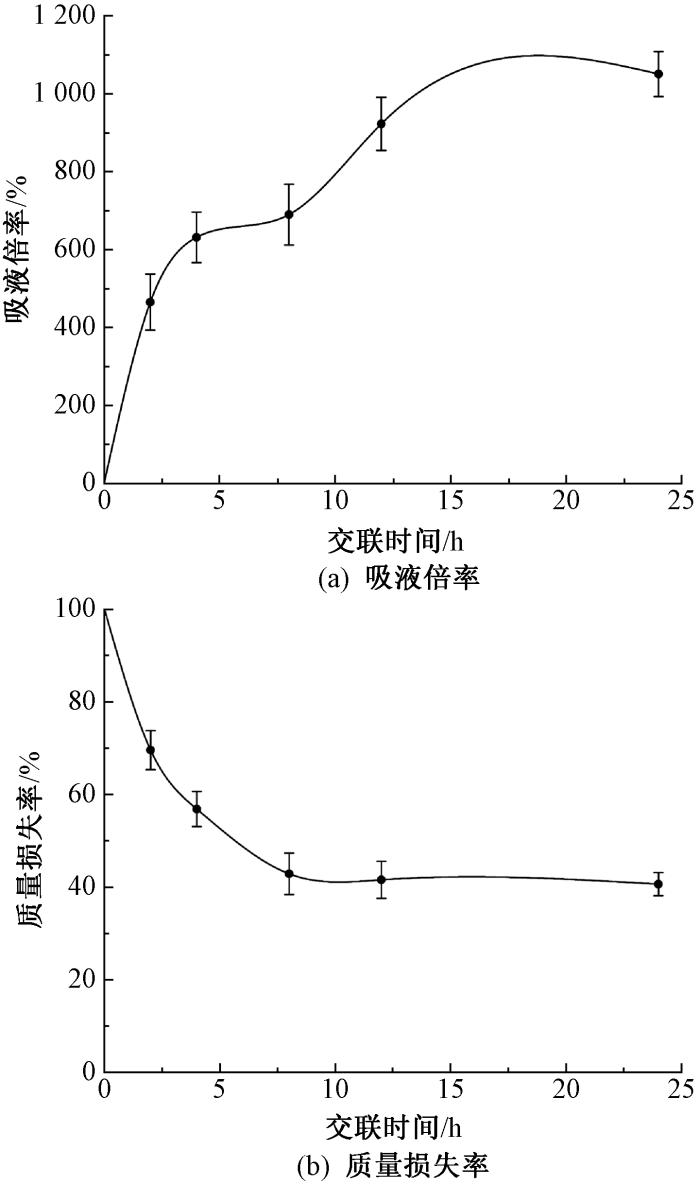

2.3.2 交联后吸液倍率和质量损失率

图6示出SA/PEO/PVP复合纳米纤维膜在不同交联时间下经PBS处理24 h后的吸液倍率和质量损失率。

图6

图6

不同交联时间的复合纳米纤维膜在PBS溶液中处理24 h后的吸液倍率和质量损失率

Fig.6

Swelling ratio(a) and mass loss percentage(b) of composite nanofiber membranes after 24 h of treatment in PBS solution at different cross-linking times

从图6(a)可见,随着交联时间的延长,复合纳米纤维膜的吸液倍率呈上升趋势。从图6(b)可见,复合纳米纤维膜经交联改性后其质量损失率有所降低,并随着交联时间的延长而逐渐减小。其原因可能是SA分子链与Ca2+形成了稳定的凝胶网络,提高了其在水中的稳定性,从而允许材料吸水并保留更多水分。在4~8 h的交联处理过程中,纤维膜的吸液倍率趋于稳定,可能是因为进一步的交联作用导致孔隙结构闭合,减少了膜的孔隙和可吸液的空间,纤维膜达到了最大的凝胶化程度。当交联时间延长至12 h和24 h,吸液倍率和质量损失率均趋于稳定。24 h交联处理后吸液倍率达1 050.80%,质量损失率为40.63%。这可能是因为纤维膜的三维网络结构已经趋于饱和,且其高度的交联阻止了进一步的溶胀或结构变化[22]。综合来看,交联时间的增加使得原本水溶性的高分子纤维膜转变为更稳定的凝胶网络结构,显著提升了吸液能力,并减少了在PBS溶液中的质量损失率。

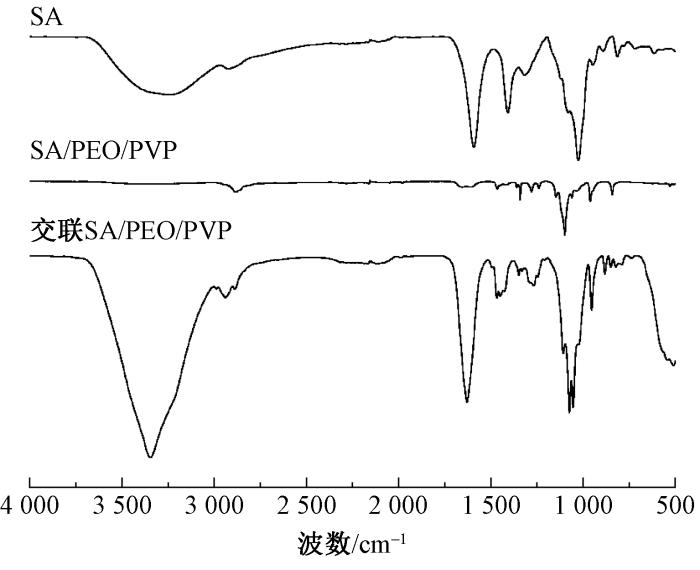

2.3.3 交联后化学结构

图7为交联改性前后复合纳米纤维膜的红外光谱图。与纯SA对比,交联SA/PEO/PVP复合纳米纤维膜中羧基(—COO—)的特征吸收峰经交联后发生了显著的变化。特别是在1 600 cm-1 附近,羧基的对称拉伸振动峰强度有所增强,并向较高波数区域移动[23-24],这表明Ca2+与SA分子链中的羧基形成了离子交联,增强了纤维膜的稳定性,表明交联结构在提升纤维膜的物理性质中起到了关键作用。此外,PEO的引入使得3 400 cm-1 附近羟基(—OH)吸收峰宽度减小,峰强减弱,反映了SA中原有氢键网络被PEO氧原子参与的新氢键所取代,破坏了SA分子内的氢键网络,提高了SA的可纺性。在交联后的复合纳米纤维膜中,1 100 cm-1 附近C—O—C的拉伸振动吸收峰发生了轻微的位移[25],表明PEO的存在对SA分子链间的相互作用产生了影响。

图7

图7

SA和交联改性前后复合纳米纤维膜的红外光谱图

Fig.7

Infrared spectroscopy images of SA and composite nanofiber membranes before and after cross-linking modification

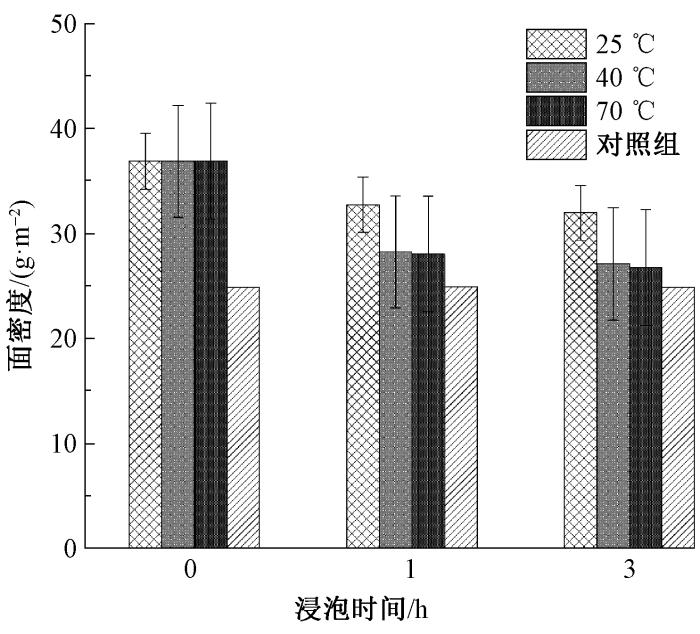

2.3.4 交联后湿热稳定性

为探究交联24 h后SA/PEO/PVP复合纳米纤维膜在模拟的人体皮肤湿热环境中的稳定性,选取没有接收纳米纤维的基布作为对照组,分别探究在不同温度、不同浸泡时间条件下纳米纤维的质量损失情况,结果如图8所示。可见,基布在各项实验条件下几乎无质量损失,因此可排除其对实验结果的影响。数据显示,随着温度的升高,复合纳米纤维膜的损失量有所增加,表明材料的高温稳定性有限。相比之下,在常温条件下,纳米膜表现出较好的稳定性。浸泡时间由1 h增加至3 h,并未造成明显的额外质量损失,这表明纳米纤维膜在1 h内可能已达到损失的饱和状态。在随后的浸泡时间内,质量损失并未显著增加,表明材料在短期使用(1 h内)后的性能保持较为稳定,随温度升高其稳定性降低。

图8

图8

温度和浸泡时间对SA/PEO/PVP复合纳米纤维膜稳定性的影响

Fig.8

Influence of temperatures and soaking times on stability of SA/PEO/PVP composite nanofiber membranes

3 结论

本文研究使用去离子水为纺丝溶剂,采用小型直线槽状静电纺丝装置制备了海藻酸钠/聚环氧乙烷/聚乙烯吡咯烷酮(SA/PEO/PVP)复合纳米纤维膜,并对其微观形态及交联改性处理后的性能进行分析,得到如下主要结论。

1)以去离子水为溶剂,在不改变材料生物相容性的前提下,成功克服了使用静电纺丝技术从SA溶液制备纳米纤维的难题,通过与PEO、PVP共混,制备出纤维直径为240 nm、形貌优良且无串珠结构的SA/PEO/PVP复合纳米纤维膜,不仅规避了有机溶剂可能造成的污染问题,还实现了SA基纳米纤维的稳定制备。因其独特的物理和化学特性,该复合纳米纤维膜在创伤治疗领域具有广泛的适用性,尤其是在促进伤口愈合和预防创伤粘连方面展示出优异的应用潜力。

2)经CaCl2质量分数为3.0%的无水乙醇溶液交联处理后,复合纳米纤维膜的耐水性能得到了改善,微观形貌显示交联后的纤维从丝束状转换成为连续的膜状结构,其中24 h交联处理的效果最为显著,吸液倍率达到1 050.80%,质量损失率为40.63%,表明材料具备良好的吸液能力和结构稳定性,为基于湿性愈合理论的创伤敷料开发提供了新的策略和方向。

参考文献

Recent trends on wound management: new therapeutic choices based on polymeric carriers

[J].

DOI:10.1016/j.ajps.2019.11.008

PMID:33363624

[本文引用: 1]

Wound healing is an unmet therapeutic challenge among medical society since wound assessment and management is a complex procedure including several factors playing major role in healing process. Wounds can mainly be categorized as acute or chronic. It is well referred that the acute wound displays normal wound physiology while healing, in most cases, is seemed to progress through the normal phases of wound healing. On the other hand, a chronic wound is physiologically impaired. The main problem in wound management is that the majority of wounds are colonized with microbes, whereas this does not mean that all wounds will be infected. In this review, we address the problems that clinicians face to manage while treat acute and chronic wounds. Moreover, we demonstrate the pathophysiology, etiology, prognosis and microbiology of wounds. We further introduce the state of art in pharmaceutical technology field as part of wound management aiming to assist health professionals to overcome the current implications on wound assessment. In addition, authors review researches which included the use of gels and dermal films as wound healing agents. It can be said that natural and synthetic drugs or carriers provide promising solutions in order to meet the wound management standards. However, are the current strategies as desirable as medical society wish?© 2020 Shenyang Pharmaceutical University. Published by Elsevier B.V.

A review on wound dressings with an emphasis on electrospun nanofibrous polymeric bandages

[J].

海藻酸盐医用敷料研究进展

[J].

Progress in research on alginate medical dressings

[J].

生物质纤维医用敷料研究进展

[J].

Research progress on biomass fiber medical dressings

[J].

静电纺丝在多组分医用敷料中的应用及进展

[J].

Application and progress of electrospinning in multicomponent medical dressings

[J].

静电纺丝在生物医用材料领域的应用综述

[J].

A review of the application of electrospinning in the field of biomedical materials

[J].

Advances in wound dressing based on electrospinning nanofibers

[J].

Alginate-based nanomaterials: fabrication techniques, properties, and applications

[J].

Alginate: enhancement strategies for advanced applications

[J].

Bacterial alginate production: an overview of its biosynthesis and potential industrial production

[J].

海藻酸钠纺丝原液粘度研究

[J].

Study on the viscosity of sodium alginate spinning solution

[J].

聚乙烯醇/海藻酸钠/黄连素医用敷料制备及其性能

[J].

Preparation and properties of polyvinyl alcohol/sodium alginate/berberine medical dressings

[J].

Fabrication challenges and trends in biomedical applications of alginate electrospun nanofibers

[J].

Effect of solution composition variables on electrospun alginate nanofibers: response surface analysis

[J].

CS/PVP复合纳米纤维膜的制备及其表征

[J].

Preparation and characterization of CS/PVP composite nanofiber membranes

[J].

Advances on alginate use for spherification to encapsulate biomolecules

[J].

Ions-induced gelation of alginate: mechanisms and applications

[J].

DOI:10.1016/j.ijbiomac.2021.02.086

PMID:33617905

[本文引用: 1]

Alginate is an important natural biopolymer and has been widely used in the food, biomedical, and chemical industries. Ca-induced gelation is one of the most important functional properties of alginate. The gelation mechanism is well-known as egg-box model, which has been intensively studied in the last five decades. Alginate also forms gels with many other monovalent, divalent or trivalent cations, and their gelation can possess different mechanisms from that of Ca-induced gelation. The resulted gels also exhibit different properties that lead to various applications. This study is proposed to summarize the gelation mechanisms of alginate induced by different cations, mainly including H, Ca, Ba, Cu, Sr, Zn, Fe, Mn, Al, and Fe. The mechanism of H-induced gelation of alginate mainly depends on the protonation of carboxyl groups. Divalent ions-induced gelation of alginate show different selection towards G, M, and GM blocks. Trivalent ions can bind to carboxyl groups of uronates with no selection. The properties and applications of these ionotropic alginate gels are also discussed. The knowledge gained in this study would provide useful information for the practical applications of alginate.Copyright © 2021 Elsevier B.V. All rights reserved.

Physicochemical properties of alginate-based films: effect of ionic crosslinking and mannuronic and guluronic acid ratio

[J].

一种直线形槽状无针式静电纺丝装置及纺丝方法:106048749A

[P]. 2016-10-26.

A linear groove needleless electrospinning device and spinning method: 106048749A

[P]. 2016-10-26.

交联改性对敷料用壳聚糖/聚氧化乙烯纳米纤维膜性能的影响

[J].

DOI:10.13475/j.fzxb.20200203306

[本文引用: 1]

为改善壳聚糖基纳米纤维膜的耐水性和结构稳定性,对静电纺丝制得的壳聚糖/聚氧化乙烯(PEO)纳米纤维膜进行戊二醛交联改性,研究不同交联时间下纳米纤维膜在模拟人体缓冲液中微观形态结构、化学结构和结晶结构的变化,并对交联后纤维膜的耐水性和力学性能进行表征。结果表明:壳聚糖基纳米纤维膜经戊二醛交联处理后,在缓冲液中浸泡24 h纤维形态的稳定性得到明显改善,且随着交联时间的增加,纤维膜在缓冲液中的吸水率逐渐增加,溶失率逐渐降低;交联改性改变了壳聚糖大分子固有的结晶结构,使纤维膜的初始模量提高,力学强度随交联时间的增加先增加后降低。

The effect of cross-linking modification on the properties of chitosan/polyethylene oxide nanofiber membranes for dressing application

[J].

DOI:10.13475/j.fzxb.20200203306

[本文引用: 1]

In order to improve the structural stability and water resistance of chitosan-based nanofiber membranes, the glutaraldehyde cross-linking modification to the chitosan/polyoxyethylene nanofiber membranes prepared by electrospinning was carried out. Then,the nanofiber membranes of different crossing-linking time were immersed into phosphate buffer saline simulating body fluid environment in order to characterize its microstructure, chemical and crystalline structure, and the water resistance and mechanical properties was measured. The experimental results show that after glutaraldehyde cross-linking modification, the stability of the fiber structure is improved after soaking in the buffer for 24 h,and the water absorption ratio of nanofiber membranes in phosphate buffer saline gradually increases with the cross-linking time and the dissolution ratio gradually decreases, revealing that the cross-linking treatment has a positive effect on the structural stability and water resistance of the fiber membrane. It is also found that the cross-linking modification causes a strong interaction between the molecules, and changes the inherent crystalline structure of chitosan macromolecules, resulting in an increase in the initial modulus of the fiber membrane. In addition, the research shows that the mechanical strength of the nanofiber membranes increases first and then decreases with the extension of the cross-linking time. The cross-linking treatment increases both the strength and brittleness of the fiber membranes.

静电纺胶原/聚环氧乙烷纳米纤维膜的制备及其性能

[J].

Preparation and properties of electrospun collagen/polyethylene oxide nanofiber membranes

[J].

Preparation and properties of a multi-crosslinked chitosan/sodium alginate composite hydrogel

[J].

Electrospinning alginate/polyethylene oxide and curcumin composite nanofibers

[J].

京公网安备11010502044800号

京公网安备11010502044800号