纳米纤维通常是指直径小于1 μm的纤维状材料,其可由多种材料制成,包括聚合物、无机物、金属和生物材料等,具有高比表面积等优势[1],在过滤、生物医学、电子、能源、化学等众多领域具有巨大的应用潜力。

1 简要发展历史

静电纺丝技术可追溯到1934年及以前,但静电纺能制备纳米纤维的报道首次出现于1996年,随后引发了一系列的研究,并掀起了静电纺纳米纤维的研究热潮。对于涉及气流的静电纺丝,Reneker等[14] 在2000年对静电纺纤维形成机制和射流不稳定性的报道中引入了空气动力学的概念,描述了空气阻力对射流的影响,为气流辅助静电纺丝技术的研究做了重要的铺垫。2004年Um等[15]报道了关于气流辅助的静电纺丝工艺,将气流和静电纺丝进行结合。随着时间的推移,气流辅助静电纺丝的研究越来越多,总体而言,气流辅助的静电纺丝技术可分为4种主要类型:气流辅助的针型静电纺丝、气流辅助的无针静电纺丝、气泡静电纺丝和离心静电纺丝。其中,气泡和离心静电纺也可归在气流辅助的无针静电纺类型,但其各自具有独特的特点。本文以此为基础,对气流辅助静电纺丝技术进行详细介绍。

2 外部气流作用原理

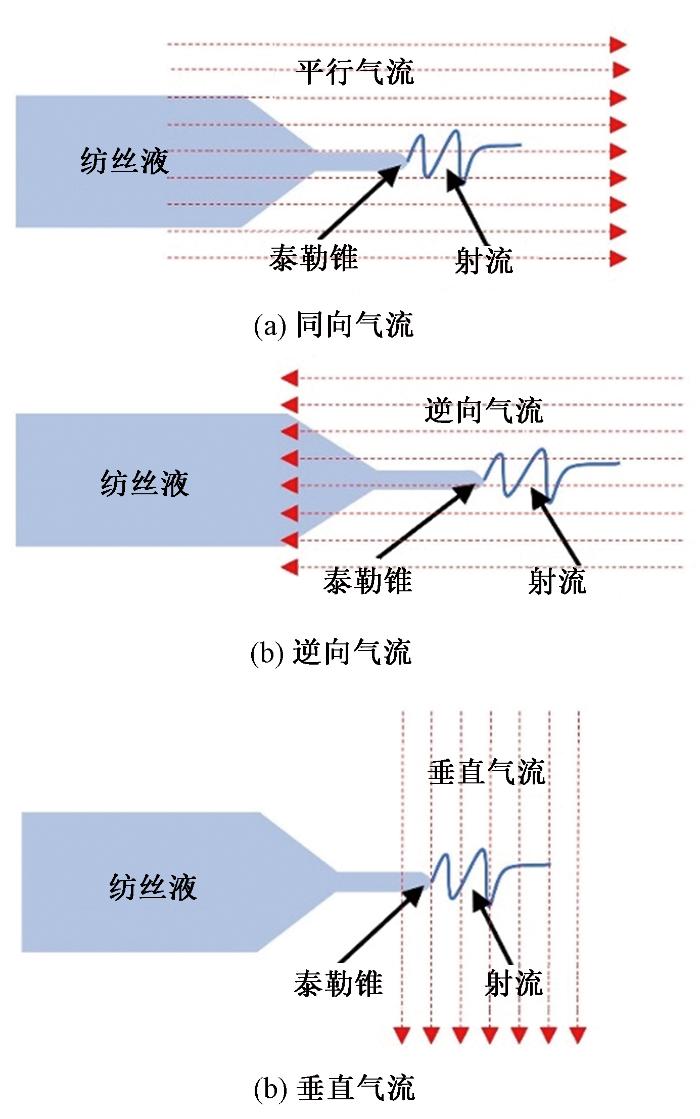

在静电纺丝过程中,载电聚合物射流及其最终形成的纤维始终受高电场作用,其电场力的作用方向主要沿喷嘴指向收集器。外部气流的引入会对射流施加额外的作用力,其与电场力的叠加可改变射流以及纤维的飞行和沉积轨迹及形貌。该作用有助于改善纤维的取向、排列和直径控制,调节产品性能。

图1

图1

气流对静电纺丝射流的不同作用形式示意图

Fig.1

Schematic illustration of airflow action on electrospinning jet.

(a) Same direction; (b) Reverse direction; (c) Vertical direction airflow

此外,气流还会对溶剂的挥发过程产生影响,其效果取决于纺丝液中溶剂的挥发能力以及纺丝液在不同浓度条件下的流变学性质。气流对纤维的固化呈现出多样化的影响。对于部分聚合物溶液体系,这些因素共同作用导致了更细纤维的形成,同时也提高了成纤速率,从而增加了纳米纤维的产量。高压雾化气流静电纺纳米纤维产量是传统针头静电纺丝的100倍,如表1所示。

表1 气流辅助静电纺纳米纤维产量

Tab.1

气流可在静电纺丝的多个阶段引入,包括射流形成区域、鞭动区域以及纤维收集区域。在射流和鞭动阶段引入气流,能够有效促进纤维的牵伸和细化过程。然而,气流的引入也会加速纤维的固化,一旦固化,纤维的牵伸即告终止。这2种相互竞争的效应共同决定了纤维的最终直径,其结果受聚合物流体的流变特性影响。此外,在纤维收集阶段施加气流主要影响纤维的排列和堆积密度,对纤维直径的影响相对较小。

上述讨论主要针对传统的针形静电纺丝过程。然而,对于其它纺丝模式,如平板、圆盘或复合喷头等,由于聚合物流体的暴露程度、喷嘴的结构和形状的多样性,气流的作用变得更加复杂,不能将所有情况一概而论,因此,根据不同静电纺丝模式分别探讨气流在其中的辅助作用及其所带来的具体影响。

3 气流辅助的针型静电纺丝

3.1 正向气流辅助

采用正向气流是一种广泛应用的气流辅助静电纺丝技术。在该技术中,气流被引入到纺丝喷头的周围,并且其方向与聚合物溶液射流的方向保持一致。气流对射流施加了与电场力同向的流体力,从而增强了射流的牵伸效果。此外,气流还可提高纺丝区域的通风效率,促进流体纤维中溶剂的快速挥发。由于受到额外力的作用,聚合物流体在纺丝头处的流速增加,进而提高了成纤的速率。然而,过大的气流可能干扰纤维的沉积稳定性,导致纤维在气流的作用下偏离预定轨迹,逃逸到收集器以外的区域,因此,在实施正向气流辅助静电纺丝时,必须精确控制气流的大小和方向,以确保纤维能够稳定地沉积在预定的收集区域,从而获得高质量的纤维产品。

3.1.1 作用于射流区域

Um等[15]研发的同向气流辅助静电纺丝装置,通过导管引入气流,使气流平行于针型纺丝头,促使针头顶端的泰勒锥克服表面张力,形成射流。这对于难以纺丝的高黏度聚合物流体(高黏度透明质胶,HA)有较好的成纤效果。通过适当提高气流的温度,可降低聚合物溶液的黏度,并避免溶液堵塞喷嘴。之后该团队优化了该装置的工艺参数,研究了气流速度(在566.34~2 831.7 m3/h范围内)对HA纤维直径的影响,制备得到最小直径约为70 nm的HA纤维[16]。Lin等[27]采用类似方法制备了聚醚砜(PES)纳米纤维,并使用内径为0.25 mm的喷丝头进行实验,在5~10 L/min范围内改变气流速度以观察其对纤维直径的影响。发现:随着气流速度的增加,纤维直径从424 nm减小到183 nm;此外,同向气流使纺丝过程更加稳定。

除用于聚合物溶液制备纳米纤维,同向气流还可用于聚合物熔融体。Takasaki等[17] 利用激光加热,使热塑性聚氨酯(TPU)熔化,TPU熔融体在同向气流和静电力的作用下制备得到直径为0.9 μm的超细TPU纤维。

气流也可辅助静电纺丝制备双组分纤维。Duan等[18]将同向气流和同轴静电纺丝装置结合,制备了聚丙烯腈(PAN)/TPU皮芯结构的纳米纤维。纺丝装置使用2个注射器将2种不同的聚合物溶液输送到同轴纺丝头的内侧和外壁,当气体流速从30 mL/min增加至60 mL/min时,可加工溶液的总流速从5 mL/h增加到12 mL/h,并使纤维产量提高。然而,由于内部溶剂无法及时从纤维内部挥发,导致纤维直径从856 nm增加到1 017 nm。单个纺丝头的皮芯纤维最大产量约为3.6 g/h。

各组之间采用的纺丝设计,由于参数和使用的材料有较大差异,结果间缺少横向可比性,造成了分析比较各个系统之间差异的困难。

3.1.2 多针静电纺丝

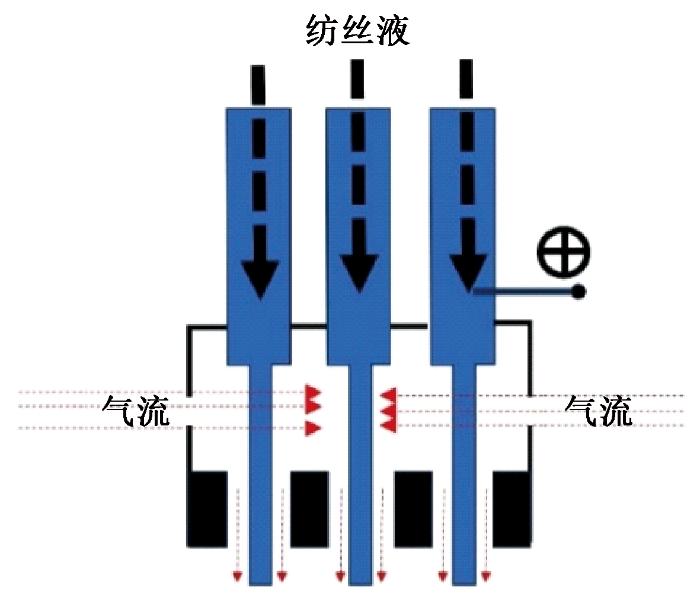

Hsiao等[19]采用多针头静电纺丝装置制备聚碳酸酯(PC)纳米纤维,器件结构如图2所示,所制备纳米纤维的直径远小于未加气流制备的纳米纤维。研究表明,采用16个并行排列的单针头组件,使PC纤维产量可达1.92 g/h左右;当气流压力从0 MPa增加到0.3 MPa时,纤维的平均直径从168 nm减小到120 nm。Zheng等[20]利用ANSYS仿真软件,对多喷丝板静电场进行仿真模拟,并调查了针头之间静电场的分布情况,预测结果显示弯曲排列的喷丝板可减少电场屏蔽效应干扰。通过气流场模拟,确定了4个气流入口,以实现对每个喷丝头均匀作用的目的,最终确定了使用5×5阵列的多针装置来制备聚环氧乙烷(PEO)纳米纤维。当气流从0 kPa增加到20 kPa时,射流无序运动增加,使得纤维沉积面积增加,但当气流从30 kPa增加到50 kPa时,由于气流的约束作用导致纤维面积减少。同时,中心纺丝头的临界电压从8 kV降低至3.4 kV,大幅缩小了喷丝头之间的临界电压差距,减少了电场屏蔽,从而提高了纺丝稳定性。

图2

图2

同向气流辅助的多针纺丝头结构示意图

Fig.2

Schematic diagram of co-directional airflow assisted multi-needle spinneret

3.2 垂直剪切式气流辅助

垂直气流的引入通常是在形成射流之后,它们对射流产生折弯效应,促使射流拉伸并改善了纤维的产量和质量。Varesano等[21]用垂直气流辅助的静电纺丝装置制备了卷曲聚酰胺6(PA6)纳米纤维,通过气流改变了PA6纤维的卷曲度。将静电纺丝装置固定于一个圆形管子的轴心位置,由管壁内测沿弧度切线方向通入气流,使气流在管道内部形成漩涡,即使微弱的漩涡式气流(如1 kPa的弱气流)也会改变纤维的路径,使它们形成类似波浪形的纤维结构。

图3

3.3 逆向气流辅助

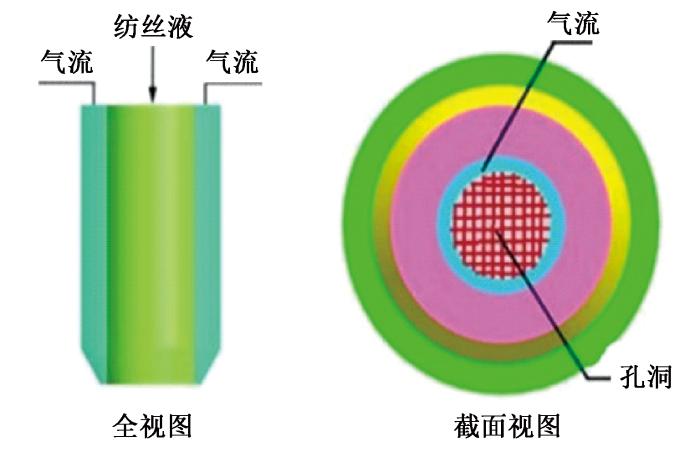

4 气流辅助的无针静电纺丝

4.1 同向气流辅助

图4

图4

气流增强的网孔静电纺丝头示意图

Fig.4

Schematic diagram of airflow-assisted electrospinning spinneret with mesh structure

除提高产量外,气流还起到促进纳米颗粒在纤维内部均匀分散的重要作用。Wei等[31]在狭缝型静电纺丝头的周围通过多个气孔引入气流,成功制备了含有氧化锌纳米颗粒的PAN纳米纤维。气流的辅助作用有助于射流的牵伸,从而使纳米颗粒在纤维中均匀分散。研究发现,当气流速度达到50 m3/h时,纺丝效果达到最佳,此时生产的纤维不仅均匀,而且没有珠状结构,平均直径为596 nm,产量高达17.33 g/h。

Wang等[24]则研究了气流对环形无针静电纺丝的影响。研究表明:同向气流作用可提升纤维产量;当使用沿着旋转路径的侧向气流时,由于垂直气流会扰乱射流并加速溶液的蒸发,同时气流的影响还会导致纤维被吹走,因此纤维产量反而下降;此外,当使用逆向气流时,纤维产量同样有所下降。

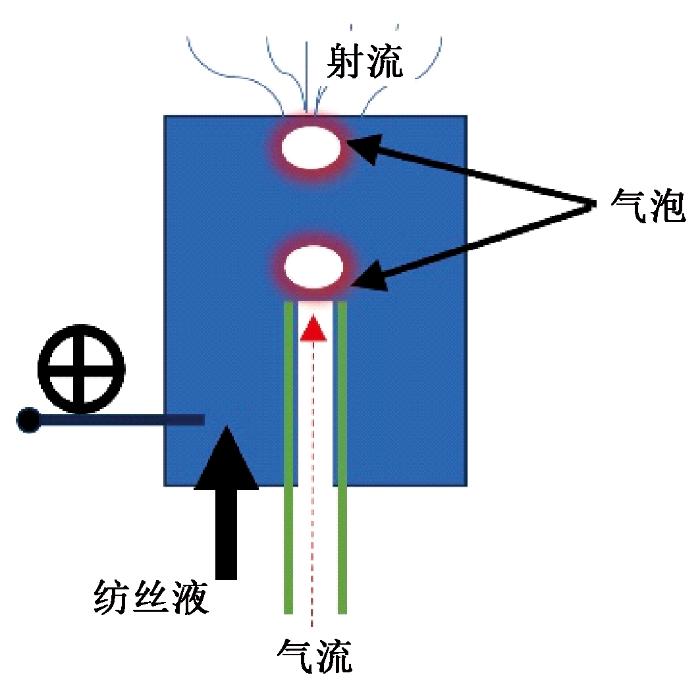

4.2 气泡静电纺丝

图5

气泡静电纺丝技术利用鼓泡原理[35]改变聚合物表面张力,在电场力作用下形成锥形气泡。该技术具备简单高效和实用性广泛等优点。然而,对于气泡纺丝纤维的形貌、应用、大批量产业化以及与气流结合纺丝方面仍需进一步探索。

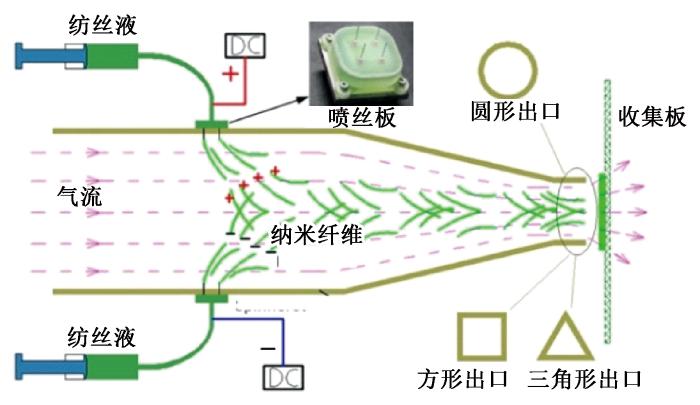

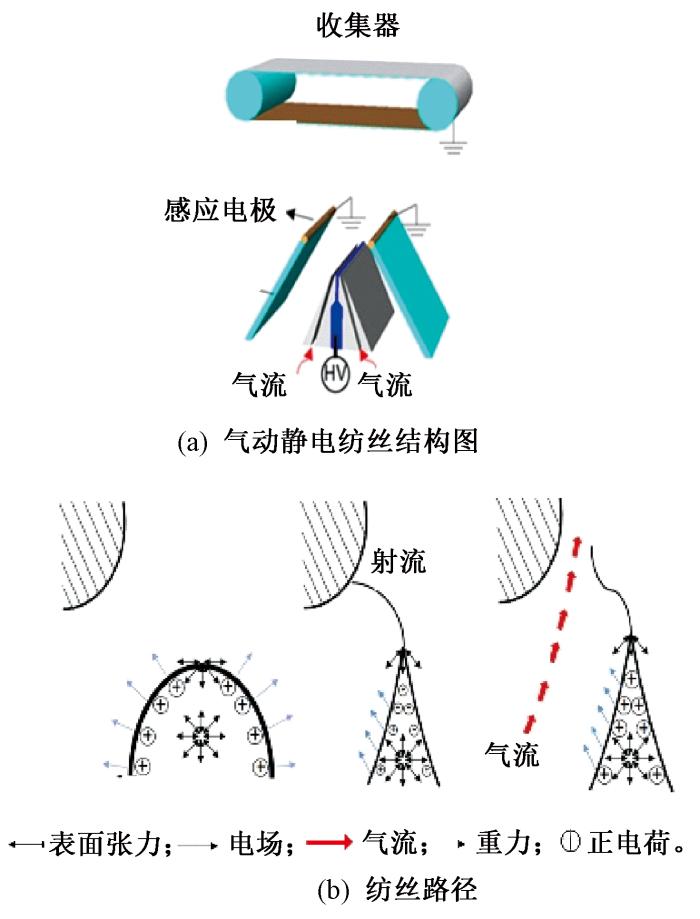

4.3 气动静电纺丝

图6

图6

气动静电纺丝示意图

Fig.6

Schematic diagram of aerodynamic electrospinning setup.

(a) Pneumatic electrospinning structure diagram; (b) Spinning trajectory

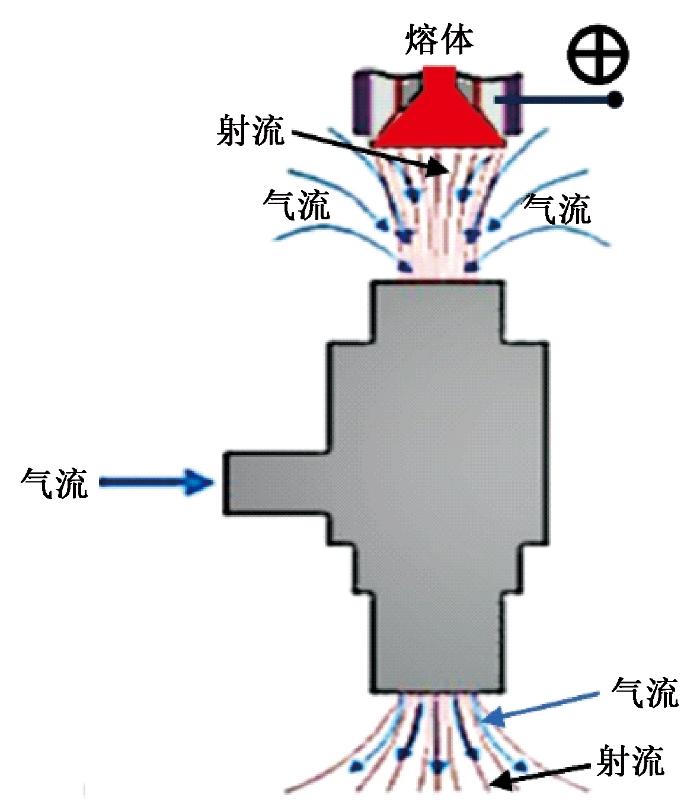

4.4 气体放大器辅助的静电纺丝

气流辅助静电纺丝技术也可通过其它装置来实现,如利用空气放大器的气体单向流动原理。Chen等[36]采用空气放大器,将聚丙烯(PP)熔体射流从放大器的吸气端引入,并在空气放大器的外侧施加高电压。在诱导电场和单向气流的共同作用下,锥形无针喷头产生多股射流,这些射流被迅速拉伸并形成大量的纤维,装置如图7所示。这种装置避免了直接在PP熔体上施加高电压,从而减少了加热线圈与高压电源之间的相互干扰。同时,采用无针熔体喷头也有效预防了PP流体的堵塞问题。空气放大器的使用使气流能够更稳定地拉伸纤维,减少了气流扰动,这有助于提高纺丝的均匀性。在45 kV电压和0.4 MPa气流条件下,该装置能够产生80股稳定的射流,纤维产量高达13.2 g/h。

图7

图7

空气放大辅助熔体静电纺丝结构图

Fig.7

Air amplification assisted melt electrospinning structure diagram

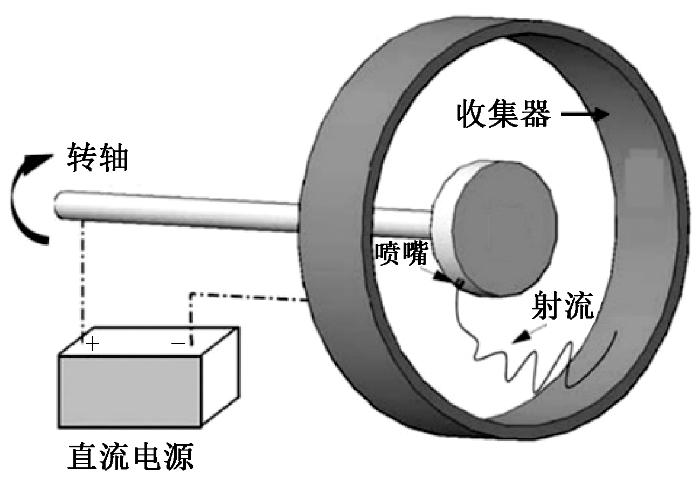

4.5 离心静电纺丝

离心静电纺丝是一种独特的气流增强型静电纺丝技术,其特点在于气流不是来自外部,而是通过纺丝头的旋转来实现的。在旋转过程中,纺丝头周围形成了一种被动式的气流,其方向与纺丝方向垂直,导致射流发生弯曲,从而增强了牵伸作用,并促进了溶剂的快速挥发。离心静电纺丝的另一个显著优势在于其可产生定向排列的纤维。关于离心静电纺丝已有相关综述报道[37],本文重点介绍几项重要的进展。

图8

离心静电纺丝在改善纤维力学性质方面的效果也得到Liao等[40]的证实。通过离心静电纺丝制备的聚乳酸和PAN等多种纳米纤维均展现出了良好的力学性能和较高的取向度。

Valipouri等[43]通过将离心装置封闭,减少了外界气流对纺丝过程的影响,从而控制了射流的运动轨迹并抑制射流溶剂的过度挥发。使用该方法可获得直径仅为136 nm的PAN超细纤维。与传统离心静电纺丝制备的纳米纤维(最小直径252 nm)相比,由这种方法制备的纤维直径减小了大约50%。Wang等[44]对离心静电纺丝的溶液储存装置进行了改进,采用多种溶液并列储存的方式,制备了聚乙烯吡咯烷酮(PVP)和聚苯乙烯(PS)复合纤维。这种装置能够调节纤维膜的接触角和渗透性能,为设计具有特殊功能的复合纤维生物材料提供了参考。此外,Liu等[45]利用机械差速离心盘来制备熔体进行静电纺丝,成功制备了平均直径为790 nm的PP纳米纤维,且产量高达124.26 g/h。

5 主要影响参数

气流辅助静电纺丝的关键因素包括溶液参数、电压、气流速度、环境因素、气流位置和方向等,它们对纳米纤维形貌、直径、均匀性、取向度和产率有一定的影响。

5.1 聚合物溶液

5.2 电场强度

在静电纺丝技术中,电场强度对于成纤和射流的形成至关重要。然而,在气流辅助静电纺丝过程中,电场强度对于纤维直径的影响相对较小。Kong等[48]通过同向气流辅助的静电纺丝技术制备了PVA纤维,并通过对收集器上纤维形貌的观察,研究了电压的作用效果。研究结果表明:随着电压的增加,纤维上的串珠逐渐减少,但气流辅助无法制备出理想的纤维;在气流作用下,电压的增加并不会对纤维直径产生影响。

5.3 气流速度

6 理论模拟

在理论研究方面,除之前描述的模拟工作,也有专门的理论模拟的报道。Meng等[50]采用Fluent流体动力学软件进行数值模拟,对气流辅助的熔体静电纺丝过程进行了研究。研究表明,气流场不仅施加拉力,还产生涡流扰动,导致射流弯曲。当气流场与静电场相结合时,这种扰动增强了拉伸能力,从而通过高黏度熔体聚合物制得更细的纤维。通过研究不同距离喷头的气流速度与气流角度的关系,发现当气流位于距离喷头5 mm处时,射流可获得最佳的拉力。

Xu等[51]采用有限元方法,利用纤维的“球-弹簧”模型分析了射流的弹性伸长和弯曲变形。研究发现,气流在纺丝针头处增加溶剂挥发是导致凝胶堵塞针口的主要原因。通过优化气流引导管角度(90°)、针型(23G)和针尖暴露长度(8 mm)等工艺参数,成功制备出平均直径为310 nm的陶瓷纳米纤维膜。

7 结束语

气流辅助静电纺丝技术展现了巨大的潜力,特别是在纳米纤维制备方面,该技术在一定程度上克服了传统静电纺丝产量低的问题。通过在针式静电纺丝装置中引入气流,不仅能够加速射流的形成和提高成纤速率,还能够改变纤维的牵伸路径,促进溶剂的挥发,以及调节纤维的沉积速度,从而展现出极高的灵活性。

目前,气流辅助静电纺丝技术的研究仍面临挑战。与传统静电纺丝和熔喷技术相比,气流辅助静电纺丝尚处于发展的初级阶段,并需解决如何进一步提高产量以满足实际量产需求这一关键问题,因此需要精确控制射流,并深入研究气流与纺丝相结合的方式。此外,空气动力学与电场耦合原理在射流和高速移动的纤维状流体中的作用仍有许多不明确之处,特别是在气流和电场力的共同作用下,纤维在强烈牵伸过程中的快速干燥机制需进一步的探究。此外,与无针静电纺丝的研究相比,气流辅助的静电纺丝的研究较少,而且对一些典型设计缺少相关研究团队的重复与验证,因此,结论的普适性有待于验证。

鉴于这些问题,应加强气流辅助静电纺丝技术研发的投入,以促进纳米纤维的生产和产业化的发展。相信随着进一步的研究和努力,气流静电纺丝将有望解决现有的技术难题,并在纳米纤维制造领域实现更高的产量和更好的性能控制,从而推动该技术的商业化应用和产业升级。

参考文献

Applications of electrospun nanofibers

[J].

Electrostatic self-assembly of polysaccharides into nanofibers

[J].

Self-assembly of electrospun nanofibers into gradient honeycomb structures

[J].

High-strength and toughness carbon nanotube fiber/resin composites by controllable wet-stretching and stepped pressing

[J].

Double-stretching as an effective and generalizable strategy towards thinner nanofibers in solution blow spinning

[J].

Study on spinnability of PP/PU blends and preparation of PP/PU bi-component melt blown nonwovens

[J].

A postgraduate experiment: a study of fabricating nanofibers by electrospinning

[J].

A review of the fundamental principles and applications of solution blow spinning

[J].

Industrial upscaling of electrospinning and applications of polymer nanofibers: a review

[J].

Processing of polymer nanofibers through electrospinning as drug delivery systems

[J].

静电纺纳米纤维行业发展现状及存在问题探讨

[J].

Discussion on development and problems of electrospinning nanofiber industry

[J].

Recent progress in preparing nonwoven nanofibers via needleless electrospinning

[J].

高效无针静电纺丝研究进展

[J].

Recent development of efficient needleless electrospinning technology

[J].

Bending instability of electrically charged liquid jets of polymer solutions in electrospinning

[J].

Electro-spinning and electro-blowing of hyaluronic acid

[J].In this study, hyaluronic acid (HA) was electro-spun and electro-blown to prepare nonwoven nanofibrous membranes. Critical parameters for processing and corresponding effects on the membrane morphology were investigated using the methods of rheology and scanning electron microscopy (SEM). During electro-spinning, the optimal HA concentration window for nanofibrous formation was determined within a narrow range of 1.3-1.5 w/v %, corresponding to a solution viscosity range of 3-30 Pa s at a shear rate of 1 s(-1). SEM results indicated that, with increases in (1) the total concentration by blending of low molecular weight HA, (2) the evaporation rate by the addition of ethanol, and/or (3) the feeding rate of solution, the electro-spinning performance for creating nanofibers was improved. However, the improvement was not sufficient to achieve a consistent production of high quality nonwoven nanofiber membranes. This problem was overcome by a new electro-blowing process using the combination of air flow and electro-spinning. Although air blowing at room temperature around the spinneret orifice did not exhibit a remarkable enhancement of nanofiber formation of HA, the performance was significantly improved with an increase in the air blowing rate. SEM results showed that the temperature of air-blowing was the most effective parameter in ensuring HA nanofiber formation. As the temperature of the blown air increased from 25 to 57 degrees C, the nanofiber formation became consistent and uniform. A high quality HA nonwoven membrane of nanofibers was successfully produced by blowing air at 57 degrees C with a 70 ft(3)/hr flow rate.

Formation of water-resistant hyaluronic acid nanofibers by blowing-assisted electro-spinning and non-toxic post treatments

[J].

Preparation of ultrafine polyurethane fiber web by laser-electrospinning combined with air blowing

[J].

Air-blowing-assisted coaxial electrospinning toward high productivity of core/sheath and hollow fibers

[J].

Effect of air blowing on the morphology and nanofiber properties of blowing-assisted electrospun polycarbonates

[J].

Highly efficient air-assisted multi-jet electrospinning with curved arranged spinnerets

[J].

Crimped polymer nanofibres by air-driven electrospinning

[J].

Concentrated multi-nozzle electrospinning

[J].

DOI:10.1007/s12221-019-8984-y

[本文引用: 2]

The multi-nozzle electrospinning is under extensive investigations because it is an easy way to enhance the productivity and also feasible to produce special structure fibers such as core-shell fibers and to fabricate composite fibers of those polymers that cannot form blend solution in common solvent. Control over the multi-nozzle electrospinning fibers deposition has attracted increasing attentions. The most common method was to use the auxiliary electrode. However, the concentrated effect of the works of control multi-nozzle electrospinning deposit was inconspicuous. To enhance the controlling of multi-nozzle electrospinning deposition, a set-up based oppositely charged electrospinning was designed. In this set-up the air flow was used to transport neutralized nanofibers. This electrospinning method was named oppositely charged and air auxiliary electrospinning (OCAAES). The capacity of OCAAES in deposition area and pattern controlling were investigated. By the OCAAES, concentrated and several patterned nanofibers deposition were fabricated. Results showed that nanofiber deposition area and pattern of multi-nozzle electrospinning could be controlled actively, and nanofiber deposition could be fabricated in a quick thickening rate.

Fabrication of nanofibers with ultrahigh production by a facile high pressure air-jet atomized electrospinning

[J].

Use of airflow to improve the nanofibrous structure and quality of nanofibers from needleless electrospinning

[J].

Effect of surface active agent on bubble-electrospun polyacrylonitrile nanofibers

[J].

Electro-aerodynamic field aided needleless electrospinning

[J].

Preparation of poly(ether sulfone) nanofibers by gas-jet/electrospinning

[J].

Control of macromolecule chains structure in a nanofiber

[J].

The use of air-flow impedance to control fiber deposition patterns during electrospinning

[J].

DOI:10.1016/j.biomaterials.2011.10.011

PMID:22054536

[本文引用: 1]

Electrospun non-woven structures have the potential to form bioresorbable vascular grafts that promote tissue regeneration in situ as they degrade and are replaced by autologous tissue. Current bioresorbable grafts lack appropriate regeneration potential since they do not have optimal architecture, and their fabrication must be altered by the manipulation of process parameters, especially enhancing porosity. We describe here an air-impedance process where the solid mandrel is replaced with a porous mandrel that has pressurized air exiting the pores to impede fiber deposition. The mandrel design, in terms of air-flow rate, pore size, and pore distribution, allows for control over fiber deposition and scaffold porosity, giving greater cell penetration without a detrimental loss of mechanical properties or structural integrity.Copyright © 2011 Elsevier Ltd. All rights reserved.

3D-printed electrospinning setup for the preparation of loratadine nanofibers with enhanced physicochemical properties

[J].

Batch preparation of nanofibers containing nanoparticles by an electrospinning device with multiple air inlets

[J].

DOI:10.3762/bjnano.14.15

PMID:36761678

[本文引用: 1]

With the increasing application of electrospun nanofibers, the batch preparation of high-performance functional nanofibers containing nanoparticles has become a research hotspot. As the distribution uniformity of nanoparticles in functional nanofibers has a great impact on their performance, an electrospinning device with multiple air inlets, which has a copper porous spinneret, is proposed to obtain functional nanofibers with higher yield and more uniform distribution of nanoparticles. The mechanism of batch preparation of functional nanofibers containing ZnO nanoparticles by the device was studied through experiments and theoretical analysis. The experimental data are in good agreement with the theoretical analysis results, which showed that under the appropriate voltage (50 kV) and air flow (50 m/h), the device could keep ZnO nanoparticles contained in the spinning solution evenly dispersed during the spinning process, thus obtaining functional nanofibers with more uniform distribution of ZnO nanoparticles, whose quality and yield were higher than those prepared by other high-yield electrospinning devices.Copyright © 2023, Wei et al.

Bubble electrospinning for mass production of nanofibers

[J].

Double- nozzle air-jet electrospinning for nanofiber fabrication

[J].

Bubble electrospinning with an auxiliary electrode and an auxiliary air flow

[J].

气泡静电纺丝工艺与装置研究进展

[J].气泡静电纺丝技术是基于蜘蛛纺丝原理与气泡动力学提出的一种新型纺丝技术。本文的研究目的在于介绍气泡静电纺丝技术以及其相关研究成果,为后续学习与研究提供理论依据。本文综述了气泡静电纺丝技术的发展现状,主要包括气泡静电纺丝原理、纺丝过程的影响因素以及各种气泡静电纺丝装置的纺丝原理与优势三方面。特别是气流气泡纺丝技术,利用气流代替高压静电的作用进行纺丝,更安全、简便、节能。气泡纺丝纤维形貌、成型机理、应用以及产业化生产等方面的研究则有待后续深入研究。

Review on bubble-electrospinning technology and set-ups

[J].A novel spinning technology, bubble-electrospinning, hinted by spider-spinning mechanism and bubble dynamics, is proposed. A complete review on bubble-electrospinning including its mechanism, its development, and main influence factors and different set-ups is made to elucidate the main properties and advantages of the technology. A novel technology, blown bubble spinning, proposed to fabricate nanofibers by using blowing air instead of high voltage, is more safe, simpler and more energy saving. Deeper research on bubble-electrospinning which contains morphologies, mechanisms, applications and industrial productions needs much more attention.

Large scaled fabrication of microfibers by air-suction assisted needleless melt electrospinning

[J].

Advanced centrifugal electrospinning setup

[J].

Investigation of parameters affecting PAN nanofiber production using electrical and centrifugal forces as a novel method

[J].

A comparative study of jet formation and nanofiber alignment in electrospinning and electrocentrifugal spinning systems

[J].

Stretching-induced orientation of polyacrylonitrile nanofibers by an electrically rotating viscoelastic jet for improving the mechanical properties

[J].

Centrifugal electrospinning of highly aligned polymer nanofibers over a large area

[J].

Morphological aspects of polymer fiber mats obtained by air flow rotary-jet spinning

[J].

A novel method for manufacturing nanofibers

[J].

Multi-compartment centrifugal electrospinning based composite fibers

[J].

High-efficiency preparation of polypropylene nanofiber by melt differential centrifugal electrospinning

[J].

Development of Coaxial air-blown electrospinning process for manufacturing non-woven nanofiber: I: morphology changes in non-woven nanofiber

[J].

Preparation of poly(ester imide) ultrafine fibers by gas-jet/electrospinning

[J].

Nanofiber deposition by electroblowing of PVA (polyvinyl alcohol)

[J].

Controllable preparation and formation mechanism of nanofiber membranes with large pore sizes using a modified electrospinning

[J].

Investigation on compound field of electrospinning and melt blowing for producing nanofibers

[J].

Gas-assisted electrospinning of high-performance ceramic fibers: optimal design modelling and experimental results of the gas channel of the nozzle

[J].

京公网安备11010502044800号

京公网安备11010502044800号