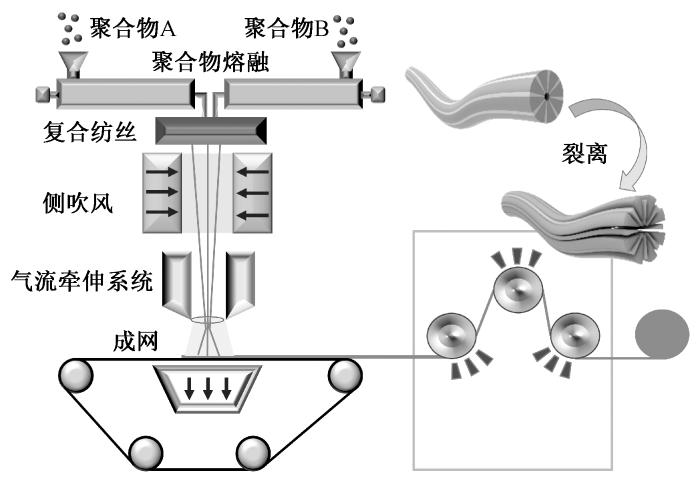

1 复合纺丝技术

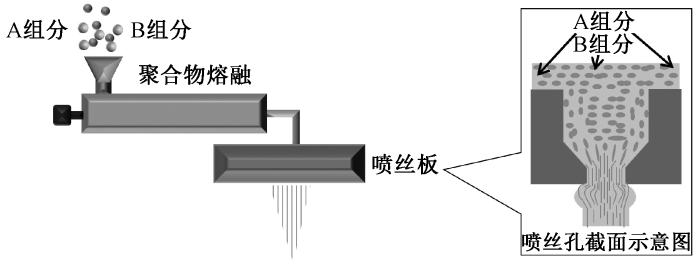

复合纺丝法根据纺丝技术可分为共混纺丝和共轭纺丝2种。

1.1 共混纺丝

图1

图2

图2

复合纤维截面示意图

Fig.2

Schematic diagram of composite fiber cross-section.

(a) Indefinite-island-fiber cross-section; (b) Fixed-island- fiber cross-section; (c) Split-fiber cross-section

不定岛纤维制备过程中,岛组分纤维的细度、数量、分布及长度都在一定范围内存在随机性。岛相聚合物的黏度高于海相聚合物,其中海相主要以低密度聚乙烯(LDPE)为主[14]。当岛组分比例较少时,岛相在海相中的分布相对稀疏,牵伸后制备的纤维线密度较小,均匀度较好[15]。但是岛组分比例过少会导致超细纤维的生产效率过低,成本过高。当岛组分比例较高时,其在海组分的分布较为密集,岛组分间易发生无规则凝聚,生产的超细纤维均匀度降低。不定岛纤维海组分经溶剂萃取,岛组分纤维线密度最细可达0.000 1 dtex[16-17],一般在0.01~0.001 dtex之间。采用共混纺丝制备超细纤维的优点是对纺丝设备的要求不高,利用常规纺丝设备就能完成,其缺点是开纤后制备的纤维细度分布不均匀,纤维尺寸不可控。

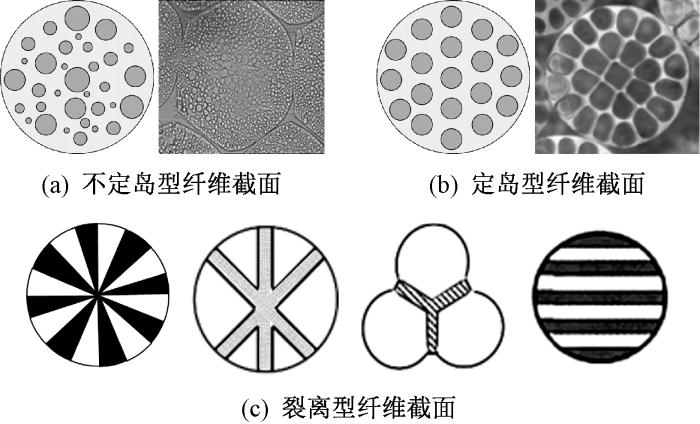

1.2 共轭纺丝

图3

共轭纺丝对纺丝组件要求极高,其工艺过程要求在一个尽可能小的空间内,并可向不同位置精确分送若干熔体流。传统喷丝板受限于钢材强度、加工精度(如研磨、钻孔、放电加工和激光处理等),导致熔体在纺丝组件内滞留时间较长(15~30 min),形成熔体流动死角,造成高聚物的热降解,导致不同纺丝温度窗口聚合物的复合纺丝难度大,易形成驻头丝并影响喷丝板的使用寿命[22]。目前美国Hills公司使用类似于制造印刷电路板的技术来制造熔体计量板和分配板,生产薄型纺丝组件,减少了因辐射和对流造成的热量损失,使得原料的范围更广、组分比例选择的范围更大,并可生产纤维截面更复杂的多组分纤维。美国Hill公司通过喷丝板的精密设计,纺制出含900个“岛”的海岛超细纤维,开纤后纤维的直径仅有300 nm。日本帝人以PET为“岛”组分,通过喷丝板设计和可形成超量“岛”断面的聚合物技术,生产的海岛纤维“岛”数量约为1 000,经开纤后得到高强度的PET纳米纤维NanofrontTM[23]。

2 复合纤维开纤技术

通过熔融复合纺丝技术制备的双组分纤维需要经过化学或物理方法实现纤维的原纤化,得到具有力学性能优异、比表面积大和可规模化生产等特点的超细纤维。海岛型复合纤维主要通过溶解去除法(去“海”留“岛”)生产超细纤维。目前适用于制造海岛型纤维的聚合物有:聚乙烯(PE)、聚丙烯(PP)、PET、聚酰胺(PA)、聚苯乙烯(PS)、热塑性聚乙烯醇(TPVA)、水溶性聚酯(WSP)等,其纤维中的岛组分有PET、PA、PP及其改性聚合物等;海组分有PS、PE(有机溶剂可溶)、COPET(热碱溶液可溶)、TPVA、WSP(热水可溶)等及其改性聚合物[11-12]。裂离型复合纤维可通过双组分的剥离实现复合纤维的原纤化。适用于生产裂离型超细纤维的聚合物有:PET、PA、PP、PE、PS、PVA、WSP等及其改性聚合物[24],需要2种聚合物在相同纺丝温度下进行匹配。

熔融复合纤维的原纤化包括化学溶剂开纤、水溶开纤、机械开纤等方法。

2.1 化学溶剂开纤法

化学溶剂开纤是利用2组分纤维中2种聚合物的不同化学特性,通过特定的化学溶剂溶解剥离其中一种聚合物,从而保留另外一种聚合物形成超细纤维的技术[25]。根据复合纺丝中所用聚合物的不同,目前主要采用苯萃取法、碱减量法及酸减量法等。

2.1.1 苯萃取法

2.1.2 碱减量法

碱减量法是一种常用于复合纤维的开纤方式,在海岛纤维中常用于定岛复合纤维的开纤,其中海组分通常采用PET/COPET作为原料。Kang等[28]对COPET/PET海岛纤维的碱减量探究表明:随着碱液浓度的增加,所获得的岛组分纤维变得更细,但碱溶液对PET组分的溶解导致纤维强力下降。目前,随着COPET制备工艺的逐渐成熟,碱减量开纤工艺也逐渐工业化。通常情况下,在NaOH质量分数为5%,碱处理时间为30 min,COPET作为海组分的工艺条件下,其溶解率可达99%以上。

生产裂离型双组分纤维时,一般复合纤维的一种组分为碱溶性聚酯(如PET、PBT、PTT及其改性聚酯等),利用碱减量法可获得良好的开纤效果,但是该开纤方法通过溶去部分纤维组分实现纤维裂离,对纤维的损伤较大,如PET/PA6双组分纤维的开纤率会随着碱液浓度、温度的增加和时间的延长而逐渐增大,但纤维损失量也增大。同时,纤维组分的大量流失破坏了纤网的微结构,导致纤网力学性能下降,纤维缠结紧密度降低,孔隙率和平均孔径增大[29]。

2.1.3 酸减量法

酸减量法主要应用于生产裂离型超细纤维。酸减量法与碱减量法类似,虽在实验室取得了阶段性成果,但在工业化生产中应用较少。复合纤维的一种组分为酸溶性聚合物,高浓度酸可使复合纤维有较大的开纤率,但纤维降解损失也大,使用酸性相对较弱的苯甲酸处理非织造布,可减少对纤维的损伤并达到开纤的目的[30]。

2.1.4 其它化学溶剂开纤法

在海岛纤维的生产中,还有其它溶剂可去除海组分,日本东丽公司生产的PS/PET定岛型纤维,以PS为海组分,经三氯乙烯(C2HCl3)溶液溶解PS组分可得到PET超细纤维。Huang等[31]以PLA为海相将聚乙醇酸(PGA)与其共混,采用高速熔融纺丝法制备了乳酸聚(PLA)/PGA海岛纤维,在三氯甲烷(CHCl3)中溶解PLA相,可生产出具有高度取向的超细、均匀且排列良好的PGA纳米纤维。

在裂离型复合纤维中,利用溶胀剂对复合纤维中2种组分的溶胀率不同,使得双组分之间界面产生剪切内应力,当剪切内应力大于界面黏合力时,复合纤维可实现裂离。但在溶胀的过程中溶剂进入纤维的非结晶区,会对纤维的物理性能(如纤维强力、抗弯刚性等)产生一定程度的影响[32]。利用超声波对低浓度碱预处理过的裂离型复合纤维进行开纤,可协同表面活性剂促使碱液沿复合纤维双组分界面侵蚀,而裂离后超细纤维的位置在超声波的作用下发生改变,进而达到裂离的效果。该方法对纤维的损伤较小,且纤维裂离较彻底,但还未在工业生产中应用。

使用化学溶剂开纤时,减量工序中产生的甲苯废水或高浓度碱减量废水,在后续处理过程中难以达标,严重污染环境,且纤维在溶剂浸泡、溶解、开纤过程中,其结构及物理性能也会受到不同程度影响。目前,在对甲苯废水的处理过程中,利用多次蒸发浓缩及降膜蒸发的方式分离甲苯和聚乙烯,大大降低苯减量废水中有毒组分的含量,且提取得到的甲苯和PE可回收利用。但碱减量废水处理涉及高含量的有机物,如对苯二甲酸钠、乙二醇,废水中化学需氧量(COD)值高达20 000 mg/L以上,生化需氧量(BOD)与COD的比值小于0.2,理论上属于不可生物降解范畴[33]。碱减量废水处理方法中,酸析法简单易行,对废水中对苯二甲酸盐(TA)的去除率在70%~99%之间,COD的去除率在50%~90%之间,但需消耗大量H2SO4且成本高[34]。碱析法虽提高了对苯二甲酸的去除率,得到的对苯二甲酸钙粒径较大,沉淀性能较好,便于分离回收,但其处置费用较高,且最终回收的对苯二甲酸钙没有利用价值[35]。膜分离技术能选择性地去除污染物,尤其是采用超滤-纳滤组合膜分离技术处理废水,能很好地达到回收利用对苯二甲酸、降低废水COD的目的,但对于高浓度废水处理效果有限[36]。目前企业常采用上流式厌氧污泥床法(UASB)[37],该方法具有高效去除有机物的优点,处理高浓度有机废水效果显著,但存在处理时间长、构筑物容积大、TA难以回收等问题,且对于沉淀物一般采用焚烧的方法处理。随着碱减量废水处理技术的持续改进,废水处理的重心应转向资源化回收和再利用,而非简单的废水净化,资源化回收的联合处理工艺将成为未来碱减量废水处理技术的主要发展趋势。

2.2 水溶开纤法

化学溶剂开纤法污染严重,且对超细纤维有不同程度的损伤,因此开发WSP及TPVA用于复合纺丝,通过热水溶解其中一种组分制备超细纤维材料成为新的研究热点[38]。

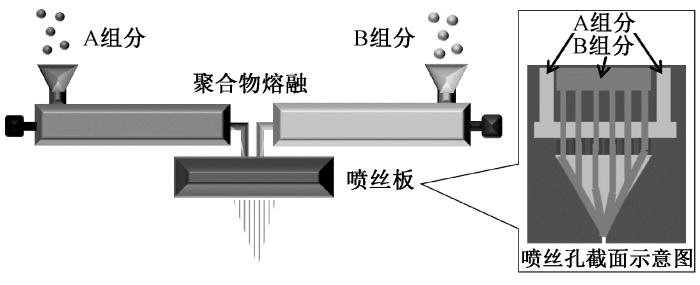

2.2.1 TPVA水溶开纤法

图4

图4

TPVA/PA复合纤维微观形貌

Fig.4

Micro-morphology of TPVA/PA composite fiber.

(a) 32-petal segmented-pie fiber; (b) 16-island sea-island fiber; (c) 32-petal segmented-pie water-soluble split fiber; (d) 16-island sea-island fiber water-soluble split fiber

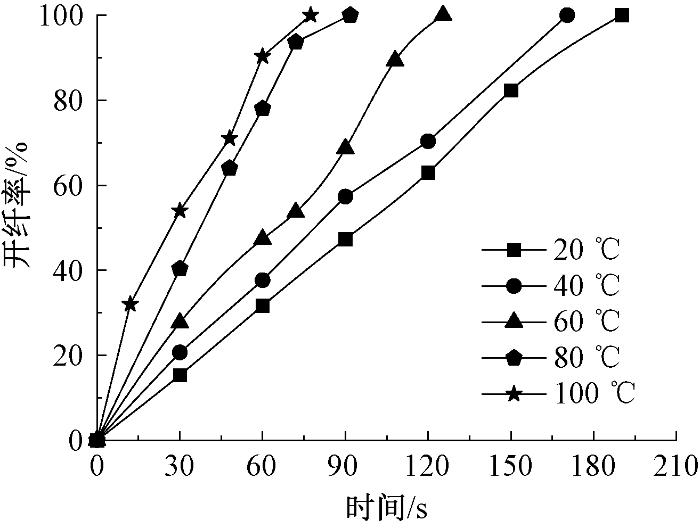

图5

图5

水溶时间和温度对复合纤维开纤的影响

Fig.5

Influence of water dissolution time and temperature on splitting of composite fiber

2.2.2 WSP水溶开纤法

日本东丽公司将WSP与PET复合纺丝制备了16、36岛的海岛型复合纤维。上海华峰超纤材料股份有限公司合成出具有常温(50 ℃以内)下溶胀率低、高温(80~100 ℃)下易溶解的水溶性共聚酯,通过与PET或PA6复合纺丝制备了定岛型复合纤维,该纤维具有常温下不易粘连、在高温下能够快速溶解于水的特性[46]。

尽管水溶性聚合物熔融纺丝具备一定的优势和潜力,但在当前工业生产中仍然面临一系列挑战。在熔融纺丝过程中,需要高度精密的生产设备来严格控制温度、湿度等参数,以确保纤维的质量和稳定性,不仅增加了生产成本,也提高了技术门槛。此外,水溶性聚合物纤维在接触水或湿度变化时可能会溶解或失去稳定性,从而影响其使用寿命和性能,因此,需要针对不同的应用场景进行纤维结构设计和处理,以提高其抗水溶性和稳定性,进而满足不同领域的需求。

2.3 机械开纤法

图6

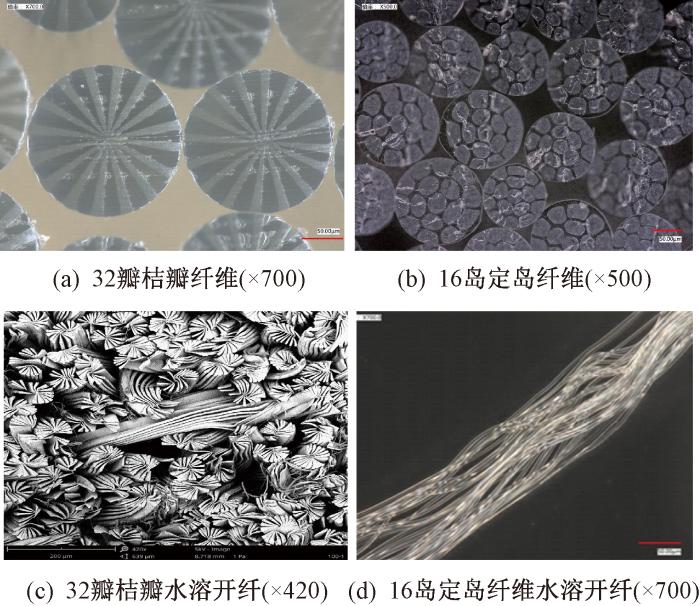

2.3.1 水刺开纤法

采用水刺工艺使裂离型复合纤维原纤化,既可使产品具有很好的物理力学性能和手感,又能极大简化生产工序,可使超细纤维特有的优异性能充分发挥,最大程度地降低产品的处理成本[47]。裂离型纤维主要以桔瓣型为主。自1999年德国Freudenberg公司开发了双组分纺黏水刺非织造布,并命名为“Evolon”以来,在纤维细旦化与复合化的发展趋势下,双组分纺黏技术再一次成为非织造领域的关注热点。美国Hills公司、德国Reifenhauser公司、美国Ason公司、荷兰Akzo公司先后开发出双组分纺黏法非织造生产技术,但Freudenberg公司采用二步法制备的桔瓣型复合纤维为实心(见图7(a)),纤维开纤过程中,单个水刺头的水刺压力在30~45 MPa之间,能耗大,仍存在不易开纤、产品均匀性差的问题,且采用二步法制备的生产效率低[48]。

图7

图7

桔瓣型复合纤维SEM照片

Fig.7

SEM images of segmented-pie composite fibers.

(a) "Evolon" microscopic morphology; (b) 8+8 hollow segmented-pie; (c) 16+16 hollow segmented-pie

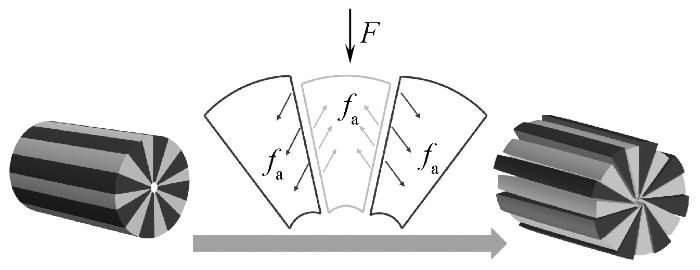

图8

目前团队已开发出16+16中空桔瓣复合纤维(见图7(c)),但制备过程中高压水射流的冲击会使得桔瓣型复合纤维迅速裂离成楔型结构并紧密堆积,无相对滑移的空间,制备的非织造布纸感严重,且撕裂强力相对较低,严重影响了非织造布的性能。桔瓣型纤维实现高效开纤与柔性缠结是该技术发展的必然要求,降低纺丝聚合物间的界面作用力是关键所在。在熔融复合纺丝过程中各组分形成的结构与其本身分子性质及与之相匹配复合纺丝的聚合物的流变性和结晶性有关[49]。Ayad等[50]通过将不同熔点的PP与PA6进行复合纺丝发现,聚合物黏度是影响界面稳定性的关键因素。Schilde等[51]将PP/PET桔瓣型纺黏非织造布通过水刺、针刺等工艺开纤发现,聚合物的流变性和结晶性影响双组分之间的界面作用力,即双组分之间的黏附力和摩擦力。卜义华[52]通过研究不同结晶度PET、PA6的表面张力,得出表面张力差异大的聚合物复合纺丝制备的桔瓣型纤维更易裂离。

钱晓明团队[53]通过模拟聚合物分子链的规整度,探究其对溶解度参数以及两相间黏附强度的影响。研究表明:降低PET分子链规整度后,界面的吸附能从574.580 kJ/mol降低至341.807 kJ/mol;当增大两相间分子链规整度的差异时,两相间溶解度参数差异增大,这对纤维的裂离有着积极的作用。根据此模拟结果,选用PA6与低结晶度聚对苯二甲酸乙二醇酯(LDPET)进行配伍纺丝,可获得易裂离的双组分复合纤维。实验结果表明:在相同的水刺压力下,LDPET/PA6纤维的开纤率高于PET/PA6纤维;在相同的开纤率下,水刺的能耗可降低15%以上(开纤率约为75%)。因此,基于裂离型复合纤维(尤其是桔瓣型复合纤维)生产超细纤维的技术中,降低聚合物双组分间的界面黏附力,制备易开纤的桔瓣型复合纤维,实现高效开纤和柔性缠结相统一是未来研究的趋势。

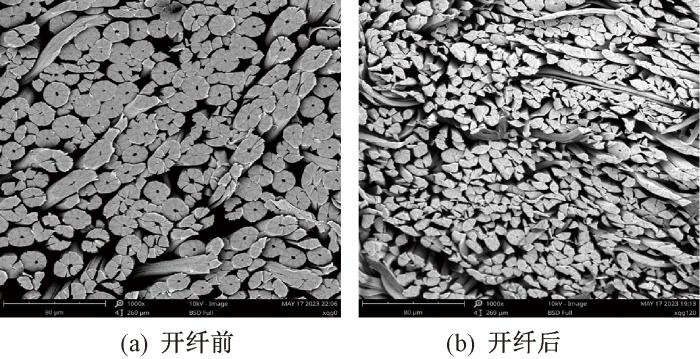

2.3.2 机械搓揉开纤法

裂离型纤维也可利用针刺工艺加工,但在实际生产中通过针刺制备的非织造布开纤率较低,同时在生产过程中需要合理选择和设定刺针型号、针刺参数(如针刺深度、密度和频率),以减少对纤维的损伤及提高纤维的开纤程度。钱晓明团队通过研究中空桔瓣型复合纤维易开纤技术,可使中空桔瓣型复合纤维不经高压水刺,而是纺黏纤网经针刺固网后经机械搓揉获得开纤,可进一步降低开纤能耗,并实现了不同风格超细纤维非织造材料的制备,开纤前后非织造材料微观形貌如图9所示。

图9

图9

开纤前后非织造布微观形貌(×1 000)

Fig.9

Microscopic morphology of nonwoven fabrics before (a) and after (b) fiber splitting (×1 000)

2.3.3 其它物理开纤法

利用复合纤维双组分在相同温度下的热膨胀性及热收缩性不同在其界面产生剪切力可实现纤维裂离,包括干热处理和湿热处理。干热法开纤效果较差,且在高温作用下非织造布中的纤维易发生粘连,影响非织造布的物理性能。湿热法开纤效果优于干热法,针对桔瓣型超细纤维非织造布开纤率低、柔软度差的问题,以高收缩聚对苯二甲酸乙二醇酯(HSPET)、PA6为原料,通过双组分纺黏水刺技术制备了HSPET/PA6超细纤维非织造布,研究表明,热收缩可促进纤维裂离,改善非织造布的柔软度及悬垂性[54]。同时,通过复合纤维轴向拉伸可实现纤维的裂离。然而,拉伸力过小,纤维双组分之间产生的剪切力小于2种聚合物界面的黏附力,纤维无法裂离;拉伸力过大,会损伤纤维,导致其力学性能下降[55]。

通过共轭纺丝法制备的裂离型纤维经物理开纤得到的超细纤维可避免在开纤过程中产生减量废水及纤维质量损失,对于清洁生产超细纤维非织造布具有很大优势。

3 熔融双组分超细纤维的应用

熔融双组分超细纤维具有纤维强度高、线密度小、抗弯刚度低、比表面积大、吸附性强等特点,广泛应用于生活生产的各个领域。

3.1 超细纤维合成革制备领域

3.2 过滤与分离领域

3.3 医用防护领域

3.4 卫生健康领域

致密的纤维结构、柔软的质地以及优异的吸水性等特点使得超细纤维材料在防螨床品、服装等领域有着广泛的应用前景。除此之外,其出色的吸水、吸尘和吸油性能以及优异的耐磨性,使之成为理想的擦拭材料,并通过特定的生产工艺赋予擦拭材料更多的功能性,用于家庭清洁、车辆护理和工业清洁等领域[62]。如由桔瓣型双组分纺黏水刺超细纤维材料制备的面膜,其结构紧密、柔软细腻,微纳米级别的纤维可保障高效吸收大量水分,由其制备的高精密擦拭材料具有不起毛、结实、力学稳定性强等特点,有卓越的无痕清洁性能,可吸收比自身质量分别高4倍的水和8倍的油。

4 结束语

通过复合纺丝技术生产超细纤维材料是批量生产高强超细纤维材料最有效的技术手段之一,具有高速、高效、高产的特点。随着碳中和与节能减排等绿色环保概念的提出,开发低能耗、无化学试剂和高效绿色开纤的方式,从而实现超细纤维的制备是熔融纺超细纤维发展的趋势。

在双组分纤维的原纤化过程中,通过化学溶剂开纤对环境污染严重,且纤维结构及物理性能也会受到不同程度的影响。开发水溶性聚合物应用于熔融复合纺丝是生产超细纤维的发展方向之一。目前,开发水溶性聚酯或热塑性聚乙烯醇用于熔融复合纺丝,制备海岛型复合纤维或裂离型复合纤维,通过热水溶解其中一种组分制备超细纤维材料已成为新的研究热点。进一步,可选用生物可降解聚合物作为超细纤维生产的原料。

采用共轭纺丝技术生产裂离型复合纤维的过程中,降低双组分间的界面黏附力是其发展的关键,应深入研究纺丝过程中聚合物分子链大小、极性强弱、聚合物结晶速率等对双组分界面作用力的影响,制备极易裂离的桔瓣型复合纤维。特别是在双组分纺黏水刺技术中,实现桔瓣型复合纤维的高效开纤与柔性缠结,可极大地拓展其应用领域。

纤维的进一步细化也是发展方向之一,目前定岛型复合纤维以16、19、37、64岛为主,最大可生产300岛复合纤维,桔瓣型复合纤维以8+8、16+16桔瓣型复合纤维为主,应进行精密组件的研发、成形工艺的优化调控,生产多岛数(>500)定岛纤维及多瓣数(如32+32)桔瓣型复合纤维。

同时,随着非织造技术的不断发展及多学科交叉理念的提倡,未来复合纤维有望通过成形技术实现纤维形态的进一步细化,通过更多先进的后整理技术实现功能化,通过原料和工艺结合实现产品的绿色化。

参考文献

Nanoval technology:an intermediate process between meltblown and spunbond

[J].

High efficiency fabrication of ultrahigh molecular weight polyethylene submicron filaments/sheets by flash-spinning

[J].

Nanofibrous membranes modified by zwitterionic polyelectrolyte brushes for effective adsorption of ciprofloxacin hydrochloride

[J].

Melt spinning of poly(lactic acid) and hydroxyapatite composite fibers: influence of the filler content on the fiber properties

[J].

Effect of wet spinning and stretching to enhance mechanical properties of cellulose nanofiber filament

[J].

Mesoporous carbon soft-templated from lignin nanofiber networks: microphase separation boosts supercapacitance in conductive electrodes

[J].

Cell environment-differentiated self-assembly of nanofibers

[J].

DOI:10.1021/jacs.6b06903

PMID:27532322

[本文引用: 2]

Employing cellular environment for the self-assembly of supramolecular nanofibers for biological applications has been widely explored. But using one precursor to differentiate the extra- and intracellular environments to self-assemble into two different nanofibers remains challenging. With the knowledge that the extracellualr environment of some cancer cells contains large amounts of alkaline phosphatase (ALP) while their intracellular environment is glutathione (GSH)-abundant in mind, we rationally designed a precursor Cys(SEt)-Glu-Tyr(H2PO3)-Phe-Phe-Gly-CBT (1) that can efficiently yield amphiphilic 2 and 2-D to self-assemble into two different nanofibers in hydrogels under the sequential treatment of ALP and GSH. We envision that, by employing a click condensation reaction, this work offers a platform for facilely postmodulation of supramolecular nanofibers, and the versatile precursor 1 could be used to kill two birds with one stone.

Free radical nanocopolymerization in AAO porous materials: kinetic, copolymer composition and monomer reactivity ratios

[J].

Efficient production of copolymerized PA6-based polymer fibers: oligomer control and direct melt spinning

[J].

A novel nano/micro-fibrous scaffold by melt-spinning method for bone tissue engineering

[J].

Studies on melt spinning of sea-island fibers: I: morphology evolution of polypropylene/polystyrene blend fibers

[J].

Studies on melt spinning of sea-island fibers: II: Dynamics of melt spinning of polypropylene/polystyrene blend fibers

[J].

Degradable side-by-side fiber of poly(butylene succinate-co-terephthalate)/poly(L-lactic acid) with half-wrinkled surfaces and fully crimped structures

[J].

Fabrication and properties of poly(L-lactide) nanofibers via blend sea-island melt spinning

[J].

Current advances on sea-island microfiber nonwoven materials preparation technology and its applications: a review

[J].

Fabrication and properties of poly(tetrafluoroethylene) nanofibres via sea-island spinning

[J].

Fiber structure development in PS/PET sea-island conjugated fiber during continuous laser drawing

[J].

Nanofiber and nanofiber powder of syndiotactic polystyrene fabricated by laser-heated drawing of sea-island-type conjugated-spun fiber

[J].

Structure development in high-speed melt spinning of high-molecular weight poly(ethylene terephthalate)/polypropylene islands-in-the-sea bicomponent fibers

[J].

Improved sensitivity of liquid sensing melt-spun polymer fibers filled with carbon nanoparticles by considering solvent-polymer solubility parameters

[J].

Hydrophilic modification of polyester/polyamide 6 hollow segmented pie microfiber nonwovens by UV/TiO2/H2O2

[J].

PET/PBT双十字形复合纤维纺丝组件及喷丝板设计

[J].

PET/PBT double cross shaped composite fiber spinning module and spinneret plate design

[J].

Business development of polyester nano fiber (NanofrontTM)

[C]//

Hybrid mixed media nonwovens composed of macrofibers and microfibers. part I: three-layer segmented pie configuration

[J].

Relationship between microstructure evolution and properties enhancement of carbon nanotubes-filled polybutylene terephthalate/polypropylene blends induced by thermal annealing

[J].

The mechanics of forming ideal polymer-solvent combinations for open-loop chemical recycling of solvents and plastics

[J].

Construction of a novel substrate of unfigured islands-in-sea microfiber synthetic leather based on waste collagen

[J].

DOI:10.1021/acsomega.1c03061

PMID:34660969

[本文引用: 1]

This study is to introduce waste collagen into an unfigured islands-in-sea microfiber nonwoven material, replacing the polyurethane impregnation section of the traditional manufacturing process with the collagen impregnation process. The modified collagen was first impregnated in polyamide/low-density polyethylene (PA/LDPE) fiber nonwoven to form a film. Then the low-density polyethylene component was extracted and dissolved in toluene, resulting in a collagen-based microfiber nonwoven substrate. Waste collagen was first modified to introduce C=C into the molecular chain to obtain vinyl collagen (CMA), and then the following film formation conditions for CMA were studied: 73% degree of substitution (DS), 3 h cross-linking time, and 0.005-0.01 wt % initiator concentration. Then, the preparation of CMA-PA/LDPE and toluene extraction processes were investigated. The optimum toluene extraction conditions were obtained as an extraction temperature of 85 °C and an extraction time of 110 min. The properties of the nonwoven materials were compared before (CMA-PA/LDPE) and after (PA-CMA) extraction. It was found that the homogeneity, tensile strength, and static moisture permeability of the PA-CMA materials prepared by CMA with 50 and 73% DS were all superior to those of PA/LDPE. In particular, the static moisture permeability of PA-CMA (691.6 mg/10 cm·24 h) increased by 36.2% compared to the microfiber synthetic leather substrate currently in the market. Using scanning electron microscopy (SEM), the continuity of a film of PA-CMA with 73% DS was observed to be better and the fibers were differentiated and relatively tighter fiber-to-fiber gap. The studied novel green process can eliminate the large amount of dimethylformamide (DMF) pollution caused by the current solvent-based polyurethane impregnation process.© 2021 The Authors. Published by American Chemical Society.

Alkaline hydrolysis and dyeing characteristics of sea-island-type ultraultra-fine fibers of PET tricot fabrics with black disperse dye

[J].

Poly (glycolic acid) nanofibers via sea-island melt-spinning

[J].

溶剂法裂离桔瓣型PET/PA6复合纤维

[J].

Solvent cleavage of orange-flap PET/PA6 composite fibers

[J].

Health hazards of child labor in the leather products and surgical instrument manufacturing industries of Sialkot, Pakistan

[J].

DOI:S0269-7491(16)32521-0

PMID:28432963

[本文引用: 1]

Child labor is a major challenge in the developing countries and comprehensive health hazard identification studies on this issue are still lacking. Therefore, the current study is an effort to highlight the health concerns of child labor exposed in the key small scale industries of Sialkot, Pakistan. Our findings revealed jolting levels of heavy metals in the urine, blood, serum, saliva, and hair samples collected from the exposed children. For example, in the urine samples, Cd, Cr, Ni, and Pb were measured at the respective concentrations of 39.17, 62.02, 11.94 and 10.53 μg/L in the surgical industries, and 2.10, 4.41, 1.04 and 5.35 μg/L in the leather industries. In addition, source apportionment revealed polishing, cutting, and welding sections in the surgical industries and surface coating, crusting, and stitching sections in the leather industries were the highest contributors of heavy metals in the bio-matrices of the exposed children, implying the dusty, unhygienic, and unhealthy indoor working conditions. Further, among all the bio-matrices, the hair samples expressed the highest bioaccumulation factor for heavy metals. In accordance with the heavy metal levels reported in the exposed children, higher oxidative stress was found in the children working in the surgical industries than those from the leather industries. Moreover, among heavy metals' exposure pathways, inhalation of industrial dust was identified as the primary route of exposure followed by the ingestion and dermal contact. Consequently, chemical daily intake (CDI), carcinogenic and non-carcinogenic hazard quotients (HQs) of heavy metals were also reported higher in the exposed children and were also alarmingly higher than the corresponding US EPA threshold limits. Taken all together, children were facing serious health implications in these industries and need immediate protective measures to remediate the current situation.Copyright © 2017 Elsevier Ltd. All rights reserved.

Fabrication and properties of poly (L-lactide) nanofibers via blend sea-island melt spinning

[J].

A hydrothermal process to turn waste biomass into artificial fulvic and hu mic acids for soil remediation

[J].

A 3D paddle-wheel type Cu(II)-based MOF with pcu topology as an efficient photocatalyst for antibiotics photodegradation

[J].

Continuous removal and recovery of tellurium in an upflow anaerobic granular sludge bed reactor

[J].

DOI:S0304-3894(16)31193-1

PMID:28043045

[本文引用: 1]

Continuous removal of tellurite (TeO) from synthetic wastewater and subsequent recovery in the form of elemental tellurium was studied in an upflow anaerobic granular sludge bed (UASB) reactor operated at 30°C. The UASB reactor was inoculated with anaerobic granular sludge and fed with lactate as carbon source and electron donor at an organic loading rate of 0.6g CODLd. After establishing efficient and stable COD removal, the reactor was fed with 10mg TeOL for 42 d before increasing the influent concentration to 20mg TeOL. Tellurite removal (98 and 92%, respectively, from 10 and 20mg TeL) was primarily mediated through bioreduction and most of the removed Te was retained in the bioreactor. Characterization using XRD, Raman spectroscopy, SEM-EDX and TEM confirmed association of tellurium with the granular sludge, typically in the form of elemental Te(0) deposits. Furthermore, application of an extracellular polymeric substances (EPS) extraction method to the tellurite reducing sludge recovered up to 78% of the tellurium retained in the granular sludge. This study demonstrates for the first time the application of a UASB reactor for continuous tellurite removal from tellurite-containing wastewater coupled to elemental Te(0) recovery.Copyright © 2016 Elsevier B.V. All rights reserved.

Effects of molecular structure of aliphatic dicarboxylic ester on the properties of water-soluble polyester for warp sizing

[J].

Poly(vinyl alcohol)/melamine phosphate composites prepared through thermal processing: thermal stability and flame retardancy

[J].

Preparation and properties of PBAT/PLA composites modified by PVA and cellulose nanocrystals

[J].

Rheological and physical properties of a nanocomposite of graphene oxide nanoribbons with polyvinyl alcohol

[J].

Effect of silver nitrate on the thermal processability of poly(vinyl alcohol) modified by water

[J].

Preparation of water-soluble electrical steel coating with SiO2 modified by glycine

[J].

水溶性聚酯的制备及其性能

[J].

Preparation and characterization of water-soluble polyester

[J].<FONT face=Verdana>Water-soluble polyester(WSP) was prepared by adding modifying monomer with sulfonic group through copolymerization.And the WSP was characterized by FTIR、DSC and X-ray.The effects of modifying monomer on WSP′s water-solubility and crystallization and thermal property were studied.And the results show that the existence of SO in the molecular chain is confirmed by FTIR,thus proving that SIPE has participated in the copolymerization;and increasing modifying monomer improves the water-solubility of polyester effectively,but it is disadvantageous to its crystallization.</FONT>

水溶性聚酯的流变行为

[J].

Rheological behavior of water-soluble polyesters

[J].<FONT face=Verdana>The water-soluble polyester(WSP) was synthesized from PTA,EG and SIPE by copolycondensation.The rheological behavior of self-produced WSP was studied with Rosand RH7 capillary rheometer.The results show that the shear viscosity of WSP declines and the non-Newton index increases with rising of the temperature.Under the same conditions,the shear viscosity of WSP is higher than that of PET.The shear viscosity of WSP is more sensitive to shear rate than PET.The viscoflow activation energy declines with increase of shear rate.The influence of the third monomer SIPE and temperature on rheological behavior was also investigated.</FONT>

梯度结构双组分纺粘水刺非织造材料的制备及其性能

[J].

Preparation and properties of bicomponent spunbond-spunlance nonwoven materials with gradient struc-ture

[J].

Hollow segmented-pie PLA/PBS and PLA/PP bicomponent fibers: an investigation on fiber properties and splittability

[J].

Effect of viscosity ratio of two immiscible polymers on morphology in bicomponent melt spinning fibers

[J].

Spunbond nonwovens made from splittable bi-component filaments

[J].

Easily splittable hollow segmented-pie microfiber nonwoven material with excellent filtration and thermal-wet comfort for energy savings

[J].

Preparation and properties of a fluffy HSPET/PA6 hollow segmented pie microfiber nonwovens

[J].

超细纤维合成革基布的制备及其性能

[J].

Preparation and properties of microfiber synthetic leather base

[J].

中空桔瓣型超细纤维/水性聚氨酯合成革的制备及性能

[J].

Preparation and properties of hollow segmented-pie microfiber/waterborne polyurethane synthetic lea-ther

[J].

基于海岛纤维的新型滤料实验研究

[J].

DOI:10.12068/j.issn.1005-3026.2017.08.021

[本文引用: 1]

研发基于超细纤维的滤料是控制PM2.5的主要技术方向之一.采用国家标准建议的实验装置,对新型超细海岛纤维滤料的过滤性能进行综合研究,得出了滤料的过滤效率、残余阻力、清灰周期等参数,并与常规针刺毡滤料和覆膜滤料对比.结果表明:海岛纤维滤料对PM2.5的计数效率为94.9%,远高于常规针刺毡滤料,与覆膜滤料相当;动态过滤过程的残余阻力低于覆膜滤料,残余阻力上升缓慢,清灰周期更长,有利于延长滤料的寿命,节约成本.

Experimental study on the new filter made from sea-islandfibers

[J].

Dopamine intercalated polyelectrolyte multilayered nanofiltration membranes toward high permselectivity and ion-ion selectivity

[J].

Facile preparation of PET/PA6 bicomponent microfilament fabrics with tunable porosity for comfortable medical protective clothing

[J].

DOI:10.1021/acsabm.2c00447

PMID:35793521

[本文引用: 1]

Medical protective materials have broadly drawn attention due to their ability to stop the spread of infectious diseases and protect the safety of medical staff. However, creating medical protective materials that combine excellent liquid shielding performance and outstanding mechanical properties with high breathability is still a challenging task. Herein, a polyester/polyamide 6 (PET/PA6) bicomponent microfilament fabric with tunable porosity for comfortable medical protective clothing was prepared via dip-coating technology and an easy and effective thermal-belt bonding process. The dip coating of the C-based fluorocarbon polymer endowed the samples with excellent hydrophobicity (alcohol contact angles, 130-128°); meanwhile, by adjusting the temperature and pressure of the thermal-belt bonding process, the porosity of the samples was adapted in the range of 64.19-88.64%. Furthermore, benefitting tunable porosity and surface hydrophobicity, the samples also demonstrated an excellent softness score (24.3-34.5), agreeable air permeability (46.3-27.8 mm/s), and high hydrostatic pressure (1176-4130 Pa). Significantly, the created textiles successfully filter aerosol from the air and display highly tensile strength. These excellent comprehensive performances indicate that the prepared PET/PA6 bicomponent microfilament fabrics would be an attractive choice for medical protective apparel.

医用防护服用非织造材料的研究进展

[J].

Research progress of nonwovens for medical protective gar-ment

[J].

京公网安备11010502044800号

京公网安备11010502044800号