锂硫电池具有高于锂离子电池的理论比容量(1 675 mA·h/g)和能量密度(2 600 W·h/kg),且硫资源储量丰富,成本低廉;因此锂硫电池在众多可充电电池中崭露头角[1-2],然而,锂硫电池在电化学反应过程中面临着各方面的考验。硫和放电产物的绝缘性产生较大的极化,倍率性能变差[3-4];正极体积膨胀近80%[5-6],使结构易崩塌,电极表面开裂;中间产物的穿梭效应不仅造成金属锂负极表面腐蚀和钝化,也导致正极活性材料损失,电池库仑效率降低和容量衰减[7-8];此外还存在锂枝晶生长和转化动力学缓慢等问题。这些都严重限制了锂硫电池的实际应用开发。如何有效解决这些问题,实现高性能、低成本和高稳定性的锂硫电池,也成为重点研究内容。

中间层的概念是在2012年由Arumugam Manthiram教授提出[9]。此后,学者们尝试将对硫物种有高度限制的材料用来开发功能性中间层。功能性中间层有2种类型:第1种是在正极与隔膜之间引入自支撑的中间层[10];第2种是直接在隔膜上进行夹层修饰,一般方法有抽滤、机械涂覆[11]和原子层沉积等。为实现锂硫电池的高性能,要求中间层具有轻薄的结构、高的电导率、较大的比表面积及丰富的孔隙结构,来促进对多硫化物的捕获和催化转化,其目的是增强物理和化学吸附,减少界面电阻,提升反应动力学,因此,对于中间层的研究主要聚焦于如何抑制锂硫电池中间产物的穿梭效应,催化加速电池内部氧化还原反应进行,以达到更理想的电化学性能。通过引入中间层进行隔膜修饰,不仅在一定程度上提高了硫载量,提升了硫正极的能量密度,而且减少了非活性物质的引入,降低了对电池整体能量密度的影响,因此,独立自支撑中间层要优于传统隔膜修饰方法。通过N[12]、P[13]和B[14]等杂原子掺杂,采用不同元素或者改变掺杂量,从根本上调节材料的电子结构和极性的能力,产生更多的活性位点来锚定/催化多硫化物,促使其快速转化。

本文结合静电纺丝和高温炭化技术,将MXene纳米片负载在钴氮掺杂的柔性碳纳米纤维基底上,获得了自支撑的三维多孔纤维结构(MX-Co/N-PCNFs),用作锂硫电池中间层;并探讨了其对锂硫电池中多硫化物的吸附特性,纳米纤维夹层的有效方法可促进锂硫电池的发展和静电纺丝材料在储能领域的应用。

1 实验部分

1.1 材料与仪器

材料:聚丙烯腈(PAN,相对分子质量为150 000)、聚甲基丙烯酸甲酯(PMMA,相对分子质量为15 000)、氟化锂(LiF,分析纯),西格玛奥德里奇(上海)贸易有限公司;四水合乙酸钴(分析纯)、1,10-菲罗琳一水合物(分析纯),上海麦克林生化科技股份公司;MAX粉末(Ti3AlC2),吉林一一科技有限公司;聚偏氟乙烯(PVDF,电池级),法国阿科玛集团;导电炭黑(Super P,电池级),常州特密高石墨有限公司;盐酸(HCl,分析纯),江苏强盛生物医药公司;升华硫(S,分析纯)、N,N-二甲基甲酰胺(DMF,分析纯)、N-甲基吡咯烷酮(NMP,分析纯)、乙二醇二甲醚(DME,分析纯)、1,3-二氧戊环(DOL,>99.5%),硫化锂(Li2S),上海阿拉丁生化科技股份有限公司;科琴黑(KB,电池级),日本狮王株式会社;金属锂片(Li),天津中能锂业;隔膜(Celgard 2500),美国Celgard公司;锂硫电解液(电池级),多多化学试剂。

仪器:DW-P503-1ACD1型高压电源,东文高压电源(天津)股份有限公司;LSP-01型注射泵,兰格恒流泵有限公司;SFM-8型自动玛瑙研磨机,沈阳科晶自动化设备有限公司;DSL-1400X 型高温管式炉,合肥科晶有限公司;手套箱,上海米开罗那有限公司;BPG-AH/BH型鼓风烘箱,上海一恒科学仪器有限公司;DZF-6053型真空干燥箱,上海一恒科学仪器有限公司;VELOCITY 14R型离心机,英国Dynamica公司;Solartron Analytical 型电化学综合分析仪,阿美特克集团科学仪器;CT 3002A 型蓝电电池测试系统,武汉蓝电电子有限公司;D8 Advance型X射线衍射仪,德国Bruker公司;SPECORD S600型紫外-可见光吸收光谱,德国耶拿分析仪器股份公司;Regulus 8100型扫描电子显微镜,日本日立公司;XploRA Plus型拉曼光谱,法国Jobin Yvon; ASAP 460型比表面积和孔径分析仪,麦克默瑞提克(上海)仪器有限公司。

1.2 MXene纳米片及DMF分散液制备

MXene纳米片的合成参考了自上而下的方法,用氢氟酸对MAX相的Ti3AlC2进行刻蚀,得到了Ti3C2相[18-19]。将20 mL浓度为9 mol/L的盐酸与1 g LiF放入聚四氟乙烯烧杯中,通风橱内搅拌5 min, 然后多次少量地添加1 g的MAX粉末,将得到的混合溶液在40 ℃油浴加热24 h,在5 ℃和5 000 r/min 条件下将溶液洗至中性,得到多层MXene纳米片。采用差速离心和手摇的方式,将多层的MXene纳米片分层,获得少层的MXene纳米片。为使MXene在DMF中形成均匀分散液,以DMF置换多余水分,以10 000 r/min离心4次,期间不断更换DMF,并手动摇匀。等待离心结束,称取MXene的质量,加入定量的DMF溶剂,获得质量浓度为90 mg/mL 的MXene分散液。

1.3 MX-Co/N-PCNFs中间层的制备

将0.1 mmol的四水合乙酸钴与0.4 mmol的1,10-菲罗琳溶解于DMF中,加入90 mg/mL的MXene分散液,搅拌直至溶液混合均匀。然后在上述纺丝液中加入成炭前驱体PAN和造孔剂PMMA,其中PAN的质量分数为10%,m(PAN)∶m(PMMA)为6∶4。磁力搅拌12 h后,获得均匀的纺丝液。将纺丝液装入注射器中,设置一定参数进行静电纺丝,得到MXene负载的纳米纤维网毡。

静电纺丝参数:电压为18 kV,纺丝流速为0.8 mL/h, 针尖到滚筒的距离为18 cm。将纳米纤维网毡放入烘箱里进行预氧化处理,处理温度从室温升至260 ℃,恒温1 h,升温速率为2 ℃/min。然后,将其送入管式炉中进行高温炭化,炭化温度为 800 ℃, 升温速率为5 ℃/min,恒温2 h,保护气氛为高纯氩气。同样,将炭化得到的柔性MX-Co/N-PCNFs切成19 mm的圆片,用作锂硫电池中间层。多孔碳纳米纤维(PCNF)中间层作为对比样,不添加钴盐、氮源以及功能性材料MXene,其它条件不变。Co/N-PCNFs中间层用作对比样时,其中不添加MXene纳米片,纺丝电压为12.5 kV,其它条件与MX-Co/N-PCNFs保持一致。

1.4 正极片制备与锂硫电池组装

将升华硫与科琴黑(KB)以3∶1的质量比,用高能研磨机研磨30 min混合均匀后,放置于反应釜中。将反应釜放置在鼓风烘箱中,155 ℃下熔硫12 h, 促使硫颗粒更高地浸润到多孔碳的孔隙结构中。将碳硫复合物、PVDF、Super P以8∶1∶1的质量比在玛瑙研钵中研磨均匀,按一定比例加入NMP,形成具有合适浓稠度的浆料,用刮刀将其涂覆在平整的双面涂炭铝箔上,在真空干燥箱中烘干24 h,随后切成12 mm的极片备用,常规测试采用低硫负载为1.3~1.5 mg/cm2,高硫载量为4 mg/cm2。

以KB/S为正极片,金属锂片为负极,Celgard 2500为隔膜,Co/N-PCNFs/PCNF用作中间层,组装成CR2032型扣式电池。锂硫电解液采用的是 1.0 mol/L 双三氟甲烷磺酰亚胺锂(LITFSI)溶解于1,3-二氧戊烷和乙二醇二甲醚溶剂(V(DOL)∶V(DME)=1∶1), 其中添加了1%的硝酸锂(LiNO3)。 低负载时,电解液用量为40 μL。高负载时,电解液用量为80 μL。扣式电池均在充满氩气的手套箱中组装。

1.5 Li2S6溶液配制及对称电池组装

将升华硫和硫化锂粉末(Li2S)以量比5∶1混合在体积比为1∶1的乙二醇二甲醚和1,3-二氧戊烷中,然后将上述溶液在氩气手套箱中于50 ℃搅拌24 h,形成Li2S6溶液。

对称电池采用2种同样的材料(Co/N-PCNFs或PCNF)作为电极,其直径均为12 mm。同样以Celgard 2500作为隔膜。在隔膜的两侧分别加入25 μL 0.2 mol/L Li2S6溶液,在手套箱中组装。

1.6 测试与表征

1.6.1 微观形貌及元素分布

将干燥的样品贴在黏有导电胶的扫描电镜测试台上,喷金处理1.5 min,加速电压为5 kV。在扫描电镜下观察样品形貌。

1.6.2 晶体结构及元素测试

采用X射线衍射仪表征样品内部晶体结构。扫描速度为10 (°)/min,X射线波长为0.154 05 nm。

采用拉曼光谱仪表征物质的组分及分布状况。激光波长选用532 nm,光栅刻密度为1 200,波数范围为4 000~150 cm-1,单次采集20 s,采集3次。

采用X射线光电子衍射仪探测出样品表面的分子结构及元素价态等信息。以Al Kα射线(hv=1 486.6 eV) 为激发源,工作电压为12 kV,样品尺寸为5 mm×5 mm,电流为6 mA。

1.6.3 比表面积及孔径测试

采用比表面积和孔径分析仪测算材料的比表面积、孔容和孔径分布等信息。

1.6.4 静态/动态吸附测试

将Co/N-PCNFs和PCNF中间层材料研磨成粉末后,取20 mg加入到稀释后的2 mmol Li2S6溶液中,随时观察其上清液的变化,并拍照记录保存。

借助H型电解池,其左侧放置5 mmol的Li2S6溶液,右侧放置空白的溶剂(V(DOL)∶V(DME)=1∶1), 两侧电解池中间放置的材料顺序为隔膜、中间层、隔膜,观察右侧电解池中颜色随时间由浅入深的变化,并拍照记录保存。以上操作均在氩气手套箱中进行。

1.6.5 电化性能学测试

利用电化学综合分析仪测试电池的阻抗谱(EIS), 常规电池测试频率范围为100 kHz~10 MHz, 扰动频率为5 mV。

利用电化学综合分析仪测试电池循环伏安(CV) 曲线。扫描速度为0.1 mV/s,电压范围为1.7~2.8 V。 对称电池的CV曲线测试的扫描速率为50 mV/s,电压范围在-1~1 V。

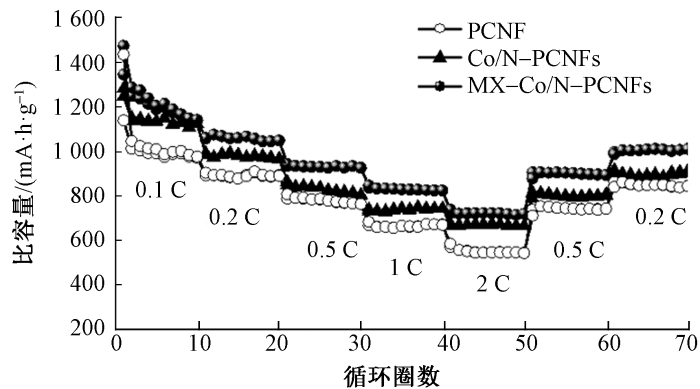

电池静置12 h后,在CT3002A型蓝电电池测试系统上进行测试倍率及循环性能。倍率由低到高分别为0.1,0.2,0.5,1和2 C(1 C=1.675 A/g), 再将倍率降低到0.5和0.2 C,分别循环10圈。

恒流充放电性能测试在室温下进行。样品静置12~14 h后,测试其在低负载0.2 C倍率及高负载0.5 C倍率下的循环情况。

2 结果与讨论

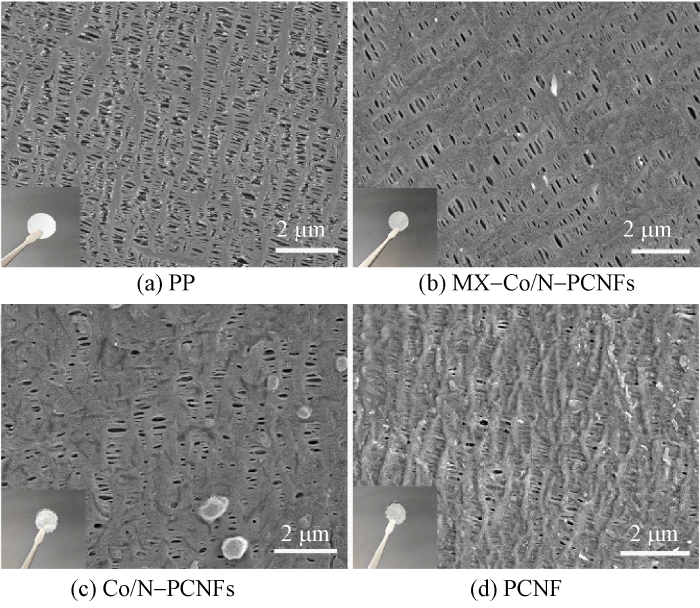

2.1 MX-Co/N-PCNFs中间层的形貌表征

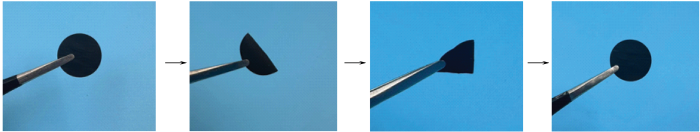

通过对MX-Co/N-PCNFs中间层进行弯折后展开,并无明显裂痕(见图1),证明添加MXene和钴氮掺杂后,其柔韧性不降反增,得益于MXene的柔性特质。

图1

图1

柔性MX-Co/N-PCNFs中间层弯折前后照片

Fig.1

Photo of flexible MX-Co/N-PCNFs intermediate layer before and after bending

图2

图2

3种不同中间层的微观形貌

Fig.2

Morphology of three different interlayers. (a)PCNF; (b)Co/N-PCNFs; (c)MX-Co/N-PWFs; (d)Cross section of MX-Co/N-PCNFs

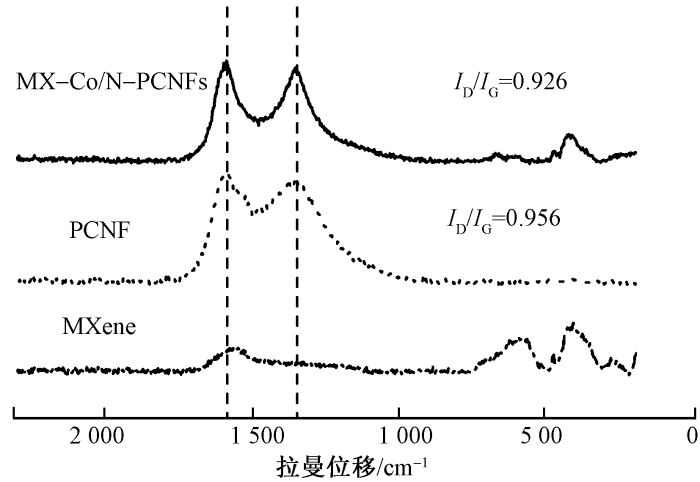

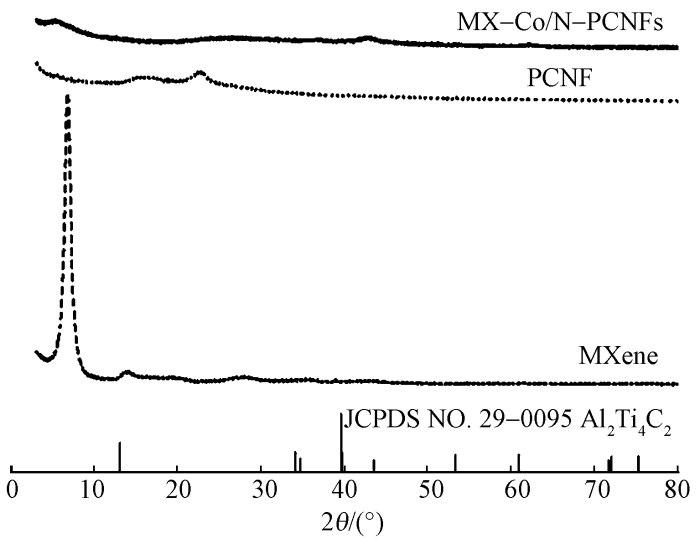

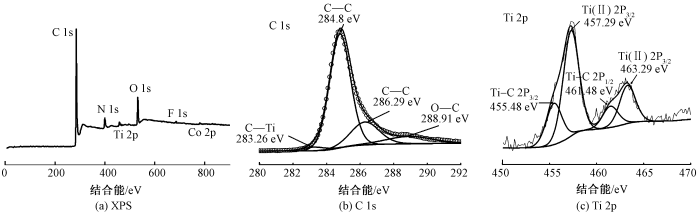

2.2 MX-Co/N-PCNFs中间层结构分析

为进一步探究MX-Co/N-PCNFs的组成和结构,测试其拉曼图谱,如图3所示。可以看出,位于 410、602 cm-1处的特征峰代表着典型的Ti3C2Tx MXene, 而且只观察到在1 565 cm-1处的石墨峰。PCNF纤维显示出2个峰,位于 1 343 cm-1(D峰)和1 589 cm-1(G峰)。通过对比发现,MX-Co/N-PCNFs显示出位于1 581、1 354、605和425 cm-1处4个峰,验证了MXene与钴氮掺杂的碳纳米纤维良好的结合。同时,借助ID/IC值(D峰与G峰强度比值)对材料的石墨化进行分析。D峰为C原子晶格缺陷,G峰为C原子Sp2杂化的面内伸缩振动,D峰越大C原子晶格缺陷越多。ID/IG值越高,表明缺陷越多,石墨化程度越低。MX-Co/N-PCNFs的ID/IG 值为0.926,小于PCNF的0.956,说明其有更高的石墨化程度。

图3

图4

图5

Ti2p精细谱(见图5(c))分峰拟合出的Ti(Ⅱ)2p3/2和Ti(Ⅱ)2p1/2的结合能为457.29和463.29 eV,Ti—C键通过拟合结果,对应的相对原子含量为28.06%。证明了MX-Co/N-PCNFs表面的元素分布状况。通过XPS对样品结构表征,可以证明MX-Co/N-PCNFs中间层内部MXene成功引入和钴氮掺杂的有效性。

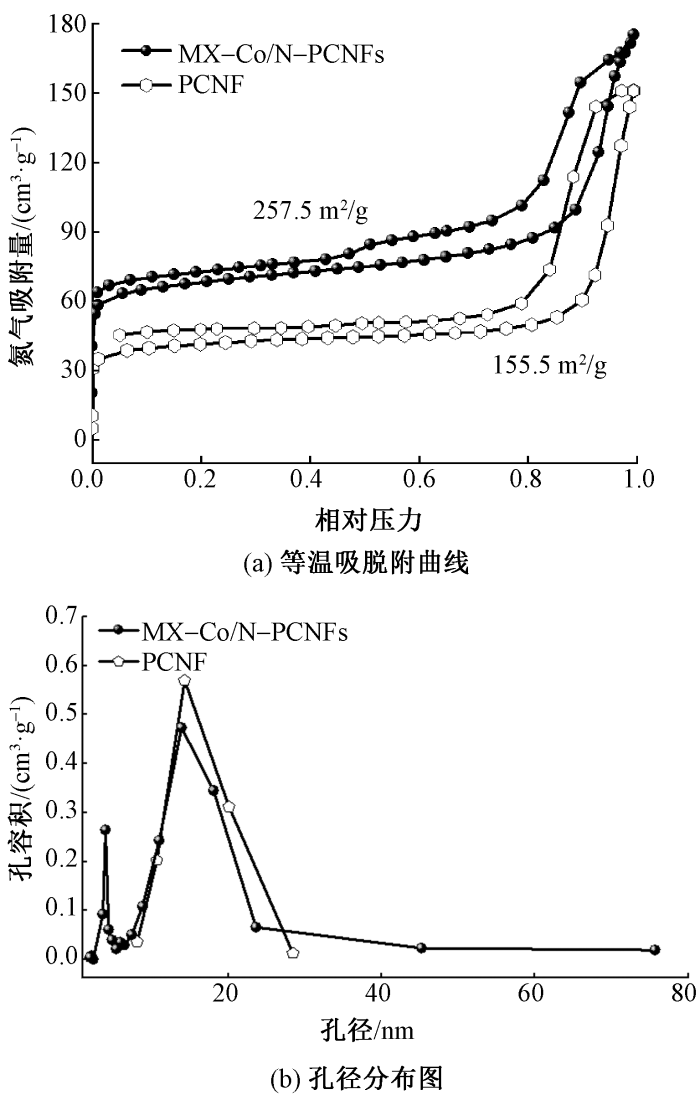

材料的高比表面积和丰富孔隙可暴露出更多的活性位点,物理限制多硫化物的穿梭,因此,采用 N2吸脱附曲线分析了材料内部的孔隙分布情况,结果如图6所示。MX-Co/N-PCNFs属于Ⅳ型吸附曲线,比表面积为257.5 m2/g,对比样为155.5 m2/g,相较于测得的MXene纳米片的比表面积要提升很多,其表面也有丰富的介孔,表明材料内部具有丰富的活性位点,同时更有利于电解液浸润,降低电池内阻。

图6

图6

MX-Co/N-PCNFs的比表面积分析

Fig.6

Specific surface area analysis of MX-Co/N-PCNFs

(a) The isothermal adsorption-desorption curves; (b) Pore size distribution

2.3 动/静态吸附效果验证

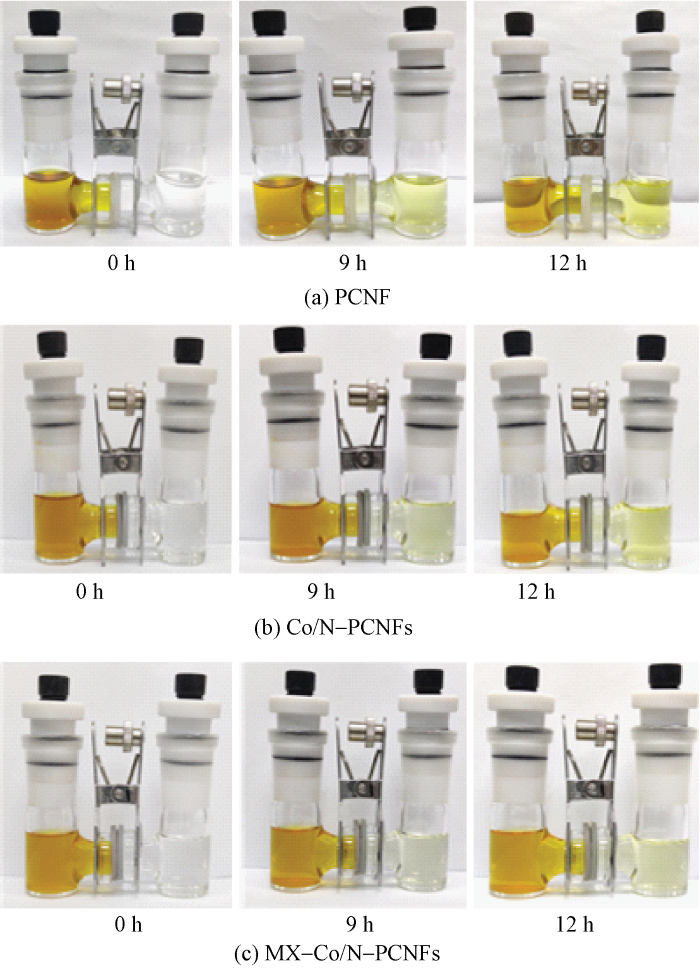

不同中间层在Li2S6溶液中的动态吸附效果如图7所示。可知随着时间的延长,PCNF和Co/N-PCNFs右侧的空白电解液逐渐变成黄色。而MX-Co/N-PCNFs在经过9 h后没有明显变化,说明添加了MXene后,阻碍多硫化物穿梭的效果更加明显。

图7

图7

不同中间层在Li2S6溶液中的动态吸附效果

Fig.7

Dynamic adsorption effect of different interlayers in Li2S6 solution

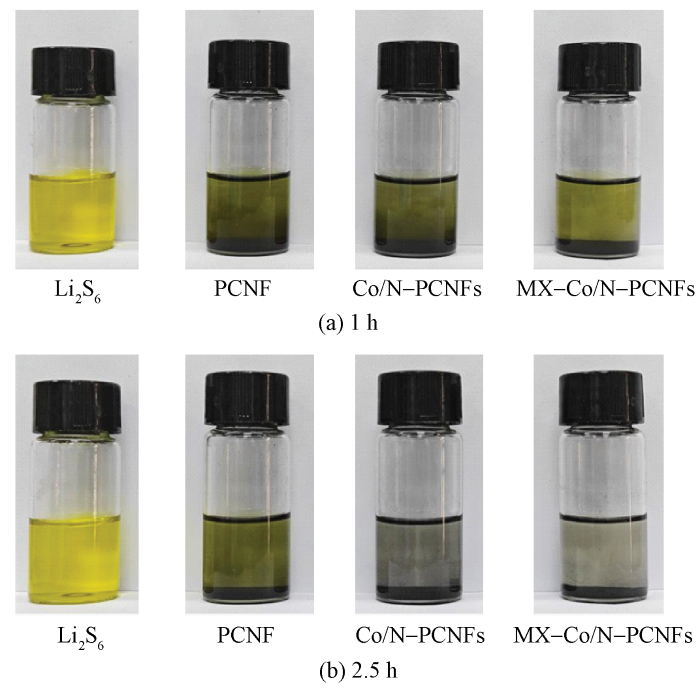

为验证MX-Co/N-PCNFs中间层的添加可实现物理和化学双重吸附限制,进行了静态吸附实验(见图8)。在2.5 h后,上清液很快变成几乎透明状态,表明了优异的吸附能力,说明其与Li2S6具有强的相互作用。高催化活性通常与多硫化物在催化剂的强吸附有关,意味着MX-Co/N-PCNFs中间层材料具有相对最佳的催化活性。

图8

2.4 电化学性能分析

2.4.1 电化学阻抗及动力学分析

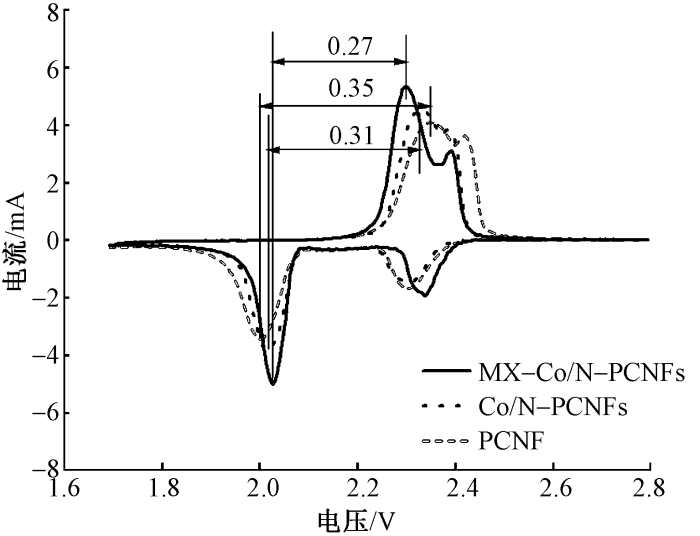

测定了装有3种不同中间层的锂硫电池阻抗(EIS)和循环伏安曲线,验证其是否加速锂硫电池氧化还原反应动力学。常规电池和对称电池循环伏安曲线可反映电池内部反应的极化现象和反应过程。图9示出装有3种中间层的锂硫电池在0.1 mV/s的扫描速度下的CV曲线对比图。基于 3种不同中间层的氧化峰和还原峰之间的电位差分别为0.27 V(MX-Co/N-PCNFs)、0.31 V(Co/N-PCNFs)和0.35 V(PCNF),其中以MX-Co/N-PCNFs中间层电压差最小,这是因为MX-Co/N-PCNFs具有较小的极化以及较强的氧化还原反应动力学。

图9

图9

含有3种不同中间层电池的CV曲线对比

Fig.9

Comparison of CV curves for cells with three different intermediate layers

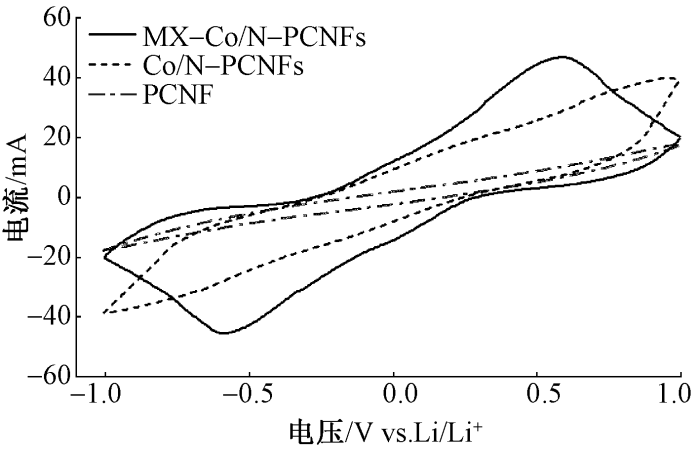

为验证MX-Co/N-PCNFs优异的电催化效果,将其作为极片,组装成对称电池,表征液相硫物种之间的液液转化过程。图10示出3种不同的中间层对称电池CV曲线。以Li2S6为电解液,在50 mV/s的扫描速度下,对称电池CV曲线均有明显的峰型。而基于MX-Co/N-PCNFs的对称电池在三者中表现出最大的氧化还原电流响应,表明其明显的液液转化过程的催化性能。

图10

图10

对称电池在50 mV/s扫描速度下的CV曲线

Fig.10

CV curves for symmetric cells scanning velocity of 50 mV/s

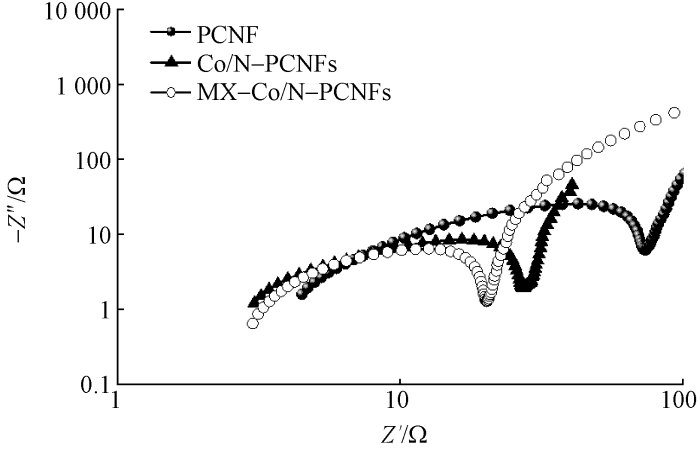

电化学阻抗谱结果(见图11)显示,引入MXene纳米片会进一步促进钴氮掺杂碳纳米纤维中间层的导电性、浸润性等,使其不仅拥有最小的界面阻抗,而且其电荷转移阻抗也最小,意味着快速的转化动力学。

图11

2.4.2 电化学循环性能分析

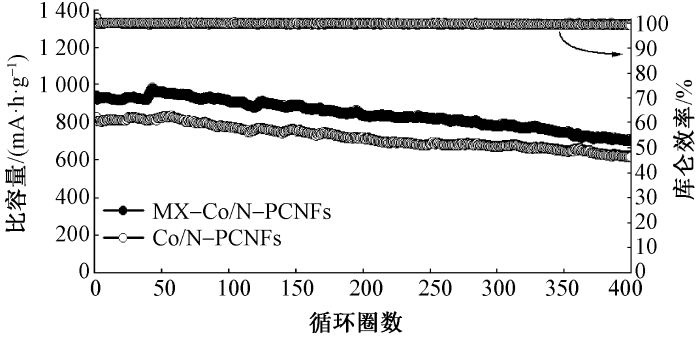

锂硫电池要求具有长期循环稳定性,因此比较了MXene纳米片的添加对电池可循环性能的影响。图12示出电池在1 C较高倍率下的循环性能。基于MX-Co/N-PCNFs中间层的电池其初始容量为944.5 mA·h/g,循环400圈,容量剩余704 mA·h/g,每圈容量衰减率为0.063%,在保持低容量衰减率的同时,MX-Co/N-PCNFs中间层的电池有着优异的放电性能。

图12

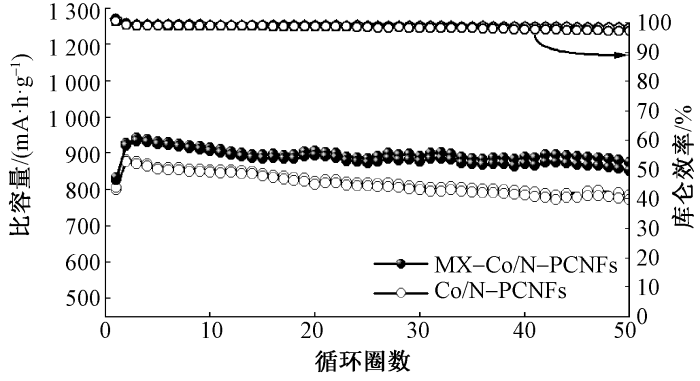

前期的循环测试均基于低硫负载情况下,为证明MX-Co/N-PCNFs中间层的优良催化和电化学性能,在4 mg/cm2的高硫负载下,探究组装不同中间层时锂硫电池在0.5 C下的循环能力,结果如图13所示。图中显示,基于MX-Co/N-PCNFs中间层的电池初始容量为921.6 mA·h/g,循环50圈后比容量剩余853 mA·h/g,优于Co/N-PCNF中间层(773 m·Ah/g), 表明MXene纳米片在提升锂硫电池高负载容量方面表现优秀。

图13

图13

高硫负载(4 mg/cm2)0.5 C倍率下的循环性能

Fig.13

Cycling performance at 0.5 C with high loading of 4 mg/cm2

2.4.3 倍率性能分析

为在实用化中缩短充放电的时间,而不影响电池的总体性能,对比了不同中间层材料在锂硫电池中的倍率特性,如图14所示。MX-Co/N-PCNFs中间层的比容量分别是1 162 mA·h/g(0.1 C)、982 mA·h/g(0.2 C)、872.5 mA·h/g(0.5 C)、782.2 mA·h/g(1 C)和708.9 mA·h/g(2 C),而当高倍率循环10圈后将倍率降为0.2 C,比容量依然可达到913.2 mA·h/g,说明其可承受不断变化的电流密度,甚至是较高的电流。而Co/N-PCNFs的比容量从0.1 C到2 C,比容量依次为1 137.1、943.1、792.5、664和586.5 mA·h/g。MX-Co/N-PCNFs中间层的倍率性能最优,凸显出其良好的电化学性能,而且倍率性能在一定程度上受锂离子迁移能力的影响,优异的充放电倍率性能也间接验证了电池内部锂离子的快速迁移。

图14

2.4.4 电池循环后表面形貌

图15

图15

低硫负载0.5 C下循环100圈后的电池内部隔膜负极形貌

Fig.15

Negative morphology of internal diaphragm of battery after 100 cycles under low sulfur load of 0.5 C

3 结论

1)通过形貌观察证明了MXene纳米片的成功制备。采用XRD与Raman等分析手段验证了MXene和钴氮掺杂碳纳米纤维(MX-Co/N-PCNFs)的复合材料的成功制备。复合后的MX-Co/N-PCNFs中间层比表面积可达257.5 m2/g,减少了MXene片层纳米片的堆叠,暴露更多的活性位点。

2)MXene纳米片具有良好的柔性特质。通过对称电池分析结果,验证了其丰富的催化位点,能够促进锂离子的扩散速率。

3)装有90 mg/mL的MX-Co/N-PCNFs中间层的电池在0.5 C倍率长循环400圈后,每圈容量衰减仅为0.063%,更是在高负载等复杂状态下,循环50圈后,容量保持在853 mA·h/g。

参考文献

ZnS-SnS@NC heterostructure as robust lithiophilicity and sulfiphilicity mediator toward high-rate and long-life lithium-sulfur batteries

[J].

DOI:10.1021/acsnano.1c00270

PMID:33764730

[本文引用: 1]

Lithium-sulfur (Li-S) batteries are severely hindered by the low sulfur utilization and short cycling life, especially at high rates. One of the effective solutions to address these problems is to improve the sulfiphilicity of lithium polysulfides (LiPSs) and the lithiophilicity of the lithium anode. However, it is a great challenge to simultaneously optimize both aspects. Herein, by incorporating the merits of strong absorbability and high conductivity of SnS with good catalytic capability of ZnS, a ZnS-SnS heterojunction coated with a polydopamine-derived N-doped carbon shell (denoted as ZnS-SnS@NC) with uniform cubic morphology was obtained and compared with the ZnS-SnS@NC heterostructure and its single-component counterparts (SnS@NC and SnS@NC). Theoretical calculations, XANES, and Raman spectrum were utilized to elucidate rapid anchoring-diffusion-transformation of LiPSs, inhibition of the shuttling effect, and improvement of the sulfur electrochemistry of bimetal ZnS-SnS heterostructure at the molecular level. When applied as a modification layer coated on the separator, the ZnS-SnS@NC-based cell with optimized lithiophilicity and sulfiphilicity enables desirable sulfur electrochemistry, including high reversibility of 1149 mAh g for 300 cycles at 0.2 C, high rate performance of 661 mAh g at 10 C, and long cycle life with a low fading rate of 0.0126% each cycle after 2000 cycles at 4 C. Furthermore, a favorable areal capacity of 8.27 mAh cm is maintained under high sulfur mass loading of 10.3 mg cm. This work furnishes a feasible scheme to the rational design of bimetal sulfides heterostructures and boosts the development of other electrochemical applications.

Designing of multifunctional and flame retardant separator towards safer high-performance lithium-sulfur batteries

[J].

New approaches for high energy density lithium-sulfur battery cathodes

[J].

DOI:10.1021/ar3001348

PMID:23054430

[本文引用: 1]

The goal of replacing combustion engines or reducing their use presents a daunting problem for society. Current lithium-ion technologies provide a stepping stone for this dramatic but inevitable change. However, the theoretical gravimetric capacity (∼300 mA h g(-1)) is too low to overcome the problems of limited range in electric vehicles, and their cost is too high to sustain the commercial viability of electrified transportation. Sulfur is the one of the most promising next generation cathode materials. Since the 1960s, researchers have studied sulfur as a cathode, but only recently have great strides been made in preparing viable composites that can be used commercially. Sulfur batteries implement inexpensive, earth-abundant elements at the cathode while offering up to a five-fold increase in energy density compared with present Li-ion batteries. Over the past few years, researchers have come closer to solving the challenges associated with the sulfur cathode. Using carbon or conducting polymers, researchers have wired up sulfur, an excellent insulator, successfully. These conductive hosts also function to encapsulate the active sulfur mass upon reduction/oxidation when highly soluble lithium polysulfides are formed. These soluble discharge products remain a crux of the Li-S cell and need to be contained in order to increase cycle life and capacity retention. The use of mesoporous carbons and tailored designs featuring porous carbon hollow spheres have led to highly stable discharge capacities greater than 900 mA h g(-1) over 100 cycles. In an attempt to fully limit polysulfide dissolution, methods that rely on coating carbon/sulfur composites with polymers have led to surprisingly stable capacities (∼90% of initial capacity retained). Additives will also play an important role in sulfur electrode design. For example, small fractions (> 3 wt%) of porous silica or titania effectively act as polysulfide reservoirs, decreasing their concentration in the electrolyte and leading to a higher utilization of sulfur and increased capacities.

Review: Li metal anode in working lithium-sulfur batteries

[J].

DOI:10.1149/2.0111801jes

[本文引用: 1]

Due to the high theoretical energy density of 2600 Wh kg(-1), lithium-sulfur batteries are strongly regarded as the promising next-generation energy storage devices. However, the practical applications of lithium-sulfur batteries are challenged by several obstacles, including the low sulfur utilization and poor lifespan, which are partly attributed to the shuttle of lithium polysulfides and lithium dendrite growth in working lithium-sulfur batteries. Suppressing lithium dendrite growth is a necessary step not only for a safe and efficient Li metal anode, but also for a high capacity cell with a high Coulombic efficiency. Herein we review the lithium metal anode protection in a polysulfide-rich environment, relative to most reviews on lithium metal anode without considering the effect of lithium polysulfides in lithium metal batteries. Firstly, the importance and dilemma of Li metal anode issues in lithium-sulfur batteries are underscored, aiming to arouse the attentions to Li metal anode protection. Specific attentions are paid to the surface chemistry of Li metal anode in a polysulfide-rich lithium-sulfur battery. Next, the proposed strategies to stabilize solid electrolyte interface and protect Li metal anode are included. Finally, a general conclusion and a perspective on the current limitations, as well as recommended future research directions of Li metal anode in lithium-sulfur batteries are presented. (C) The Author(s) 2017. Published by ECS.

Expansion and shrinkage of the sulfur composite electrode in rechargeable lithium batteries

[J].

Fabrication methods of porous carbon materials and separator membranes for lithium-sulfur batteries: development and future perspectives

[J].

The radical pathway based on a lithium-metal-compatible high-dielectric electrolyte for lithium-sulfur batteries

[J].

Functional carbons remedy the shuttling of polysulfides in lithium-sulfur batteries: confining, trapping, blocking, and breaking up

[J].

Lithium-sulphur batteries with a microporous carbon paper as a bifunctional interlayer

[J].

Efficient catalytic conversion of polysulfides in multifunctional FeP/carbon cloth interlayer for high capacity and stability of lithium-sulfur batteries

[J].

DOI:10.6023/A23010010

[本文引用: 1]

With the progress of science and the development of human society, traditional energy is increasingly exhausted, and low energy density lithium ion battery is not enough to support the demand for energy, so the development of high capacity of clean energy system is imminent. Unlike Li-ion batteries, Li-sulfur batteries have a high specific energy density (2600 Wh•kg−1), making them a promising energy storage system. However, in oxidation-reduction reaction, the shuttle effect of intermediate polysulfides (LiPSs) and slow electrochemical reaction kinetics lead to severe degradation of the cathode and anode, resulting in rapid capacity decay. In this paper, a multifunctional FeP/carbon cloth (FeP/CC) interlayer was prepared by hydrothermal synthesis. The FeP grows evenly in a “needle” shape on a smooth carbon cloth. This structure provides more active sites for Li-S batteries and greatly improves the electrochemical reaction kinetics by utilizing the catalytic ability of phosphate to Li-S batteries. In addition, carbon cloth (CC), as the matrix, can also play the role of “physical domain limiting”, thereby physically trapping LiPSs, inhibiting the shuttle effect and ensuring the cycle stability. In subsequent electrochemical tests, the FeP/CC interlayer lithium-sulfur battery had a first cycle discharge capacity of 1329 mAh•g−1 and a reversible capacity of 1100 mAh•g−1 after 100 cycles. When the sulfur load reaches 3.4 mg•cm−2 and the current density is 1 C, the cyclic capacity is stable at 495 mAh•g−1. In addition, FeP/CC showed excellent adsorption and catalytic conversion ability for LiPSs in visual adsorption experiments and ultraviolet spectrum tests. This multifunctional FeP/CC interlayer provides a feasible idea for the development of high stability and high capacity lithium-sulfur batteries.

Scaled-up fabrication of porous-graphene-modified separators for high-capacity lithium-sulfur batteries

[J].

Multifunctional effects of sulfonyl-anchored, dual-doped multilayered graphene for high areal capacity lithium sulfur batteries

[J].

DOI:10.1021/acscentsci.9b01005

PMID:31893224

[本文引用: 1]

Li-S batteries (LSBs) require a minimum 6 mAh cm areal capacity to compete with the state-of-the-art lithium ion batteries (LIBs). However, this areal capacity is difficult to achieve due to a major technical issue-the shuttle effect. Nonpolar carbon materials limit the shuttle effect through physical confinement. However, the polar polysulfides (PSs) only provide weak intermolecular interactions (0.1-0.7 eV) with these nonpolar carbon materials. The physically encapsulated PSs inside the nonpolar carbon scaffold eventually diffuses out and starts shuttling. Chemically interactive hosts are more effective at interacting with the PSs due to high binding energies. Herein, a multifunctional separator coating of nitrogen-doped multilayer graphene (NGN) and -SO containing Nafion (N-NGN) is used to mitigate PS shuttling and to produce a high areal capacity LSB. The Nafion is used as a binder instead of PVDF to provide an additional advantage of -SO to chemically bind the PS. The motive of this research is to investigate the effect of highly electronegative N and -SO (N-NGN) in comparison with the -OH, -COOH, and -SO groups from a hydroxyl graphene and Nafion composite (N-OHGN) to mitigate PS shuttling in LSBs. The highly conductive doped graphene architecture (N-NGN) provides efficient pathways for both electrons and ions, which accelerates the electrochemical conversion at high sulfur loading. Moreover, the electron-rich pyridine N and -SO show strong chemical affinity with the PS through polar-polar interactions, which is proven by the superior electrochemical performance and density functional theory calculations. Further, the N-NGN (5 h) produces a maximum areal capacity of 12.0 and 11.0 mAh cm, respectively, at 15 and 12 mg cm sulfur loading. This areal capacity limit is significantly higher than the required areal capacity of LSBs for commercial application, which shows the significant strength of N-NGN as an excellent separator coating for LSBs.Copyright © 2019 American Chemical Society.

Phosphorus doping of 3D structural MoS2 to promote catalytic activity for lithium-sulfur batteries

[J].

Direct insight into sulfiphilicity-lithiophilicity design of bifunctional heteroatom-doped graphene mediator toward durable Li-S batteries

[J].

二维纳米材料MXene及其在锂离子电池中的应用研究进展

[J].

Two-dimensional nanomaterial MXene and its research advances on applications in lithium-ion batteries

[J].

Two-dimensional ultrathin MXene ceramic nanosheets for photothermal conversion

[J].

DOI:10.1021/acs.nanolett.6b04339

PMID:28026960

[本文引用: 1]

Ceramic biomaterials have been investigated for several decades, but their potential biomedical applications in cancer therapy have been paid much less attentions, mainly due to their lack of related material functionality for combating the cancer. In this work, we report, for the first time, that MAX ceramic biomaterials exhibit the unique functionality for the photothermal ablation of cancer upon being exfoliated into ultrathin nanosheets within atomic thickness (MXene). As a paradigm, biocompatible TiC nanosheets (MXenes) were successfully synthesized based on a two-step exfoliation strategy of MAX phase TiAlC by the combined HF etching and TPAOH intercalation. Especially, the high photothermal-conversion efficiency and in vitro/in vivo photothermal ablation of tumor of TiC nanosheets (MXenes) were revealed and demonstrated, not only in the intravenous administration of soybean phospholipid modified TiC nanosheets but also in the localized intratumoral implantation of a phase-changeable PLGA/TiC organic-inorganic hybrid. This work promises the great potential of TiC nanosheets (MXenes) as a novel ceramic photothermal agent used for cancer therapy and may arouse much interest in exploring MXene-based ceramic biomaterials to benefit the biomedical applications.

Li-ion uptake and increase in interlayer spacing of Nb4C3 MXene

[J].

Electromagnetic interference shielding with 2D transition metal carbides (MXenes)

[J].

DOI:10.1126/science.aag2421

PMID:27609888

[本文引用: 1]

Materials with good flexibility and high conductivity that can provide electromagnetic interference (EMI) shielding with minimal thickness are highly desirable, especially if they can be easily processed into films. Two-dimensional metal carbides and nitrides, known as MXenes, combine metallic conductivity and hydrophilic surfaces. Here, we demonstrate the potential of several MXenes and their polymer composites for EMI shielding. A 45-micrometer-thick Ti3C2Tx film exhibited EMI shielding effectiveness of 92 decibels (>50 decibels for a 2.5-micrometer film), which is the highest among synthetic materials of comparable thickness produced to date. This performance originates from the excellent electrical conductivity of Ti3C2Tx films (4600 Siemens per centimeter) and multiple internal reflections from Ti3C2Tx flakes in free-standing films. The mechanical flexibility and easy coating capability offered by MXenes and their composites enable them to shield surfaces of any shape while providing high EMI shielding efficiency.Copyright © 2016, American Association for the Advancement of Science.

The {110} reflection in X-ray diffraction of MXene films: misinterpretation and measurement via non-standard orientation

[J].

京公网安备11010502044800号

京公网安备11010502044800号