近年来,新一代纤维素气凝胶因具有原料来源广泛、生物相容性好、密度低和孔隙率高等优点,已被应用在民用、军工以及医学等方面,并在柔性隔热领域具有广阔的应用前景[1]。由于纤维素骨架强度差,缺少强的界面作用力,受外力作用时极易坍塌导致孔洞被压缩,从而降低隔热效果,因此,赋予纤维素气凝胶良好强力和弹性,对于其在隔热保暖方面的实际应用具有重要意义[2-3]。陈彩虹[4]通过改变纳米纤维的浓度发现,制备的气凝胶其密度和导热系数随纤维素质量分数的增加而增加,当质量分数为2.5%的气凝胶经60%压缩形变后,导热系数从31.63 mW/(m·K)提高至54.62 mW/(m·K)。这是由于纯纤维素气凝胶骨架强度低,回弹性差,多孔结构发生永久性塌陷,导致气凝胶孔洞消失、孔隙率下降和孔内空气减少,使导热系数增加,隔热效果大打折扣。

目前,提高纤维素气凝胶强力和弹性的方法主要集中在增强骨架单元之间的相互作用力。例如:添加无机组分(如二氧化钛、石墨烯等)附着在纤维素纤维表面提高骨架强度,使气凝胶能够承受更大强力的压缩[5-6];通过引入反应性物质与纤维素上的羟基作用,产生强界面相互作用力(氢键和共价键)[7],保证气凝胶承受外力压缩并及时回弹。Wicklein等[8]将氧化石墨烯(GO)和海泡石纳米棒(SEP)以及交联剂硼酸添加到纤维素纳米纤维分散液(NFC)中,利用定向冷冻制备了纤维素气凝胶,其中GO和SEP可增强纤维骨架,硼酸则与羟基发生交联作用产生化学键,制备的气凝胶其弹性模量最高可达550 kPa。穆梦雅等[9]利用乙烯基三甲氧基硅烷(VTMS)和甲基丙烯酸二甲氨基乙酯(DMAEMA)的自由基聚合反应制备了共聚物PDMAEMA-co-PVTMS,然后利用该共聚物、 VTMS与纤维素纳米纤维(CNF)发生化学交联反应,以提高纤维素气凝胶的力学性能;该气凝胶经过50次循环压缩后,最大应力保持在初始值的71.3%以上。

基于以上分析,本文提出了一种简单、低成本的制备高强、柔韧的隔热纤维素气凝胶的方法,以纳米纤维素纤维(CNF)和双硅烷偶联剂1,2-二(三甲氧基硅基)乙烷(BTMSE)为原料,采用冷冻干燥方式一步构筑了CNF/BTMSE复合气凝胶,研究了BTMSE加入量对气凝胶孔洞结构、强力、压缩回弹性以及导热系数的影响。

1 实验部分

1.1 实验材料与设备

材料:羧基化纤维素纳米纤维分散液(其中CNF质量分数为1.0%),桂林奇宏科技有限公司;1,2-二(三甲氧基硅基)乙烷(BTMSE)、冰醋酸(HAc),国药集团化学试剂有限公司。

设备:SCIENTZ-10N型冷冻干燥机,宁波新芝生物科技有限公司;SU1510型扫描电子显微镜,日本日立公司;Nicolet is10型傅里叶红外光谱仪,赛默飞世尔科技(中国)有限公司;S4 TStar-TXRF型X射线光电子能谱仪,德国布鲁克AXS有限公司;testo871型红外热成像仪,上海遂欧仪器有限公司;EXCEED E43型电子万能材料试验机,美国美斯特公司;Hot Disk TPS2500型热导率仪,瑞典Hot Disk公司;YET-640L型开普森温度传感器,江苏兴化苏玛电器仪表有限公司;CFP-1100AX型多孔材料孔径测定仪,美国PMI公司。

1.2 样品制备

CNF/BTMSE复合气凝胶的制备流程如图1所示。首先,在室温条件下称取10 g质量分数为1.0%的CNF分散液,磁力搅拌均匀;之后加入适量冰醋酸调节分散液pH值至4左右,搅拌约1 h;随后将不同质量的BTMSE与CNF分散液混合搅拌 3 h 后得到均匀溶液;最后将溶液倒入聚四氟乙烯模具在液氮中冷冻3 min,冷冻后的固体样品在 -60 ℃、 1 Pa条件下继续真空冷冻干燥48 h,获得CNF/BTMSE复合气凝胶。

图1

图1

CNF/BTMSE复合气凝胶的制备示意图

Fig.1

Schematic illustration of preparation of CNF/BTMSE composite aerogel

实验中设置CNF与BTMSE的质量比分别为 4∶1、 2∶1、2∶3、2∶5,制得的气凝胶分别记作样品1#、2#、3#、4#。为进行对比实验制备了纯CNF气凝胶,所有气凝胶的厚度均在6 mm左右。

1.3 样品结构表征与性能测试

1.3.1 气凝胶微观形貌观察

将小块气凝胶置于导电胶上并喷金处理,利用扫描电子显微镜观察其微观形貌,最大加速电压为5 kV。

1.3.2 气凝胶化学结构表征

使用傅里叶红外光谱仪在全反射(ATR)模式下测试样品的化学结构,扫描波数范围为2 000~500 cm-1,扫描32次。

采用X射线光电子能谱仪(XPS)测量样品的表面元素及官能团组成。

1.3.3 导热系数测试

采用热导率仪测定气凝胶样品的导热系数。加热功率设为0.1 W,测试时间为160 s,采样间隔为 1 000 次。每个样品平行测试3次,取平均值。

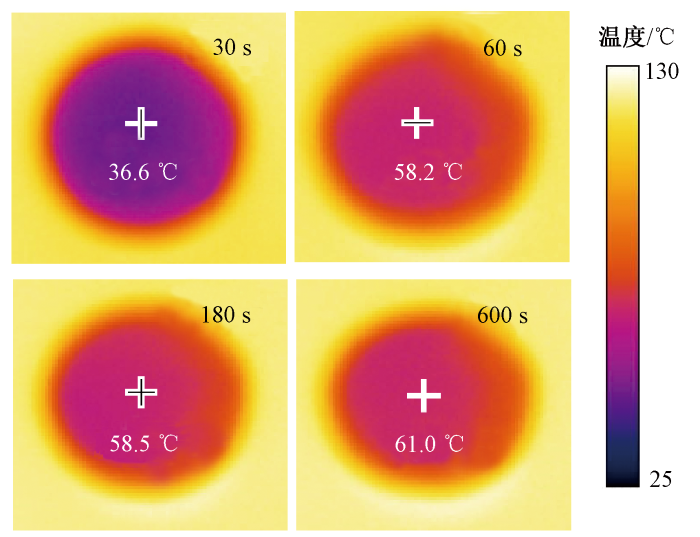

1.3.4 红外热成像表征

采用红外热成像仪测试气凝胶在130 ℃热台上的热红外成像图和辐射温度,测试距离为20 cm。

1.3.5 力学性能测试

使用电子万能材料试验机测试气凝胶的径向静态压缩性能。设置压缩回弹速度为10 mm/min,预载力为0.05 N,测试频率为20 Hz,测试过程中保证样品与压板接触良好。

使用电子万能材料试验机测试CNF/BTMSE复合气凝胶的动态压缩循环性能。将样品放置于压板中心处,压缩循环次数为200,测试速度为10 mm/min, 预载力为0.05 N,测试频率为10 Hz,压缩应变设为50%,记录应力-应变曲线。

2 结果与讨论

2.1 气凝胶形貌分析

图2

图2

气凝胶的扫描电镜照片

Fig.2

SEM images of aerogel. (a)CNF aerogel; (b)1#; (c)2#; (d)3#; (e)4#

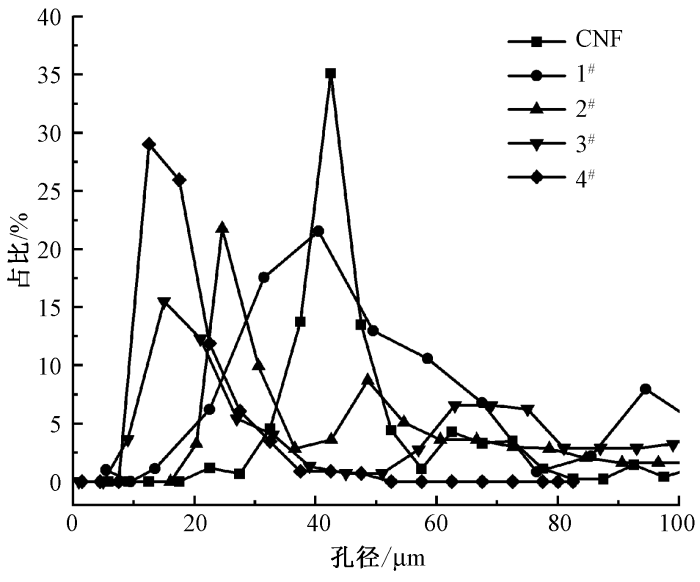

进一步测定了CNF、1#、2#、3#、4#气凝胶的孔径分布,结果如图3所示。可以看出:CNF气凝胶的孔径分布集中,平均孔径为44.2 μm;随着BTMSE添加量的增大,CNF/BTMSE复合气凝胶的孔径分布峰值逐渐左移,经计算1#、2#、3#、4#气凝胶的平均孔径分别为40.5、27.6、19、18.1 μm。经过BTMSE修饰改性后,纤维素气凝胶的孔径呈现逐渐减小的趋势,证明有交联网络的形成。同时这种孔径减小的趋势也有利于减少空气流动和碰撞,降低空气热导率和热对流,提高隔热性能。

图3

2.2 化学结构分析

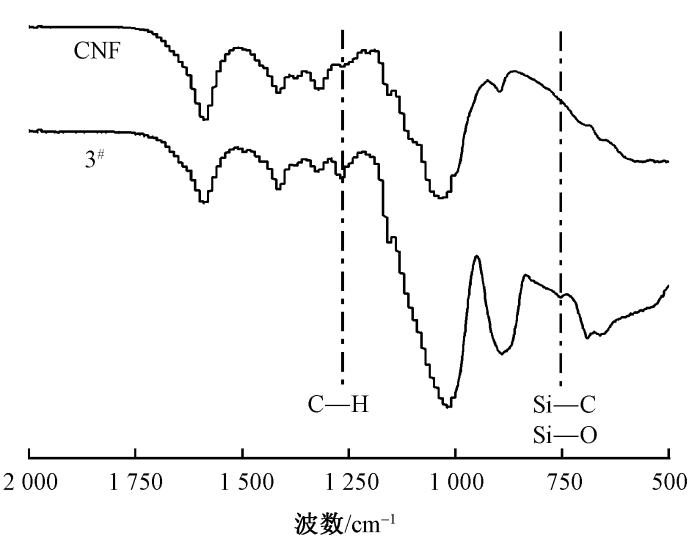

图4示出CNF和3#气凝胶的红外光谱图。CNF气凝胶在1 060 cm-1处出现了C—O伸缩振动峰,1 430 cm-1处为C—H伸缩振动峰。相比于CNF气凝胶,3#气凝胶在1 271和746 cm-1处出现了吸收峰,分别为BTMSE的Si—CH2中C—H的伸缩振动峰和Si—C、Si—O吸收峰。

图4

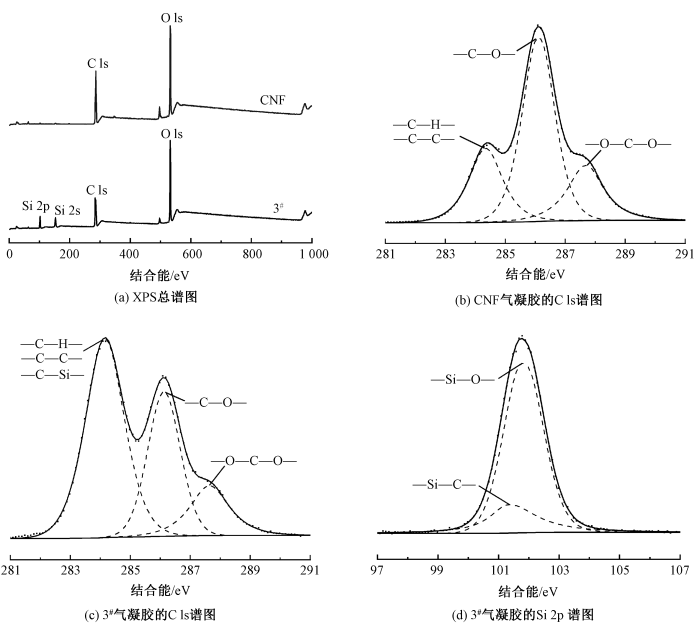

图5示出CNF和3#气凝胶的XPS谱图。可以看出,较CNF气凝胶,3#气凝胶XPS谱图中除出现C、O元素的结合能峰以外,在102.0和160.0 eV处还出现了Si2p和Si2p的特征峰。在C1s谱图中,相比于CNF气凝胶,3#气凝胶在284.1 eV处的结合能峰强度明显增大,这来自于BTMSE中的—C—Si—;3#气凝胶Si2p谱图在101.3和101.8 eV 处出现2个峰,分别对应于—Si—C—和—Si—O—。XPS和红外光谱图均表明BTMSE的成功引入,并产生化学键合。

图5

图5

CNF和3#气凝胶的XPS谱图

Fig.5

XPS spectra of CNF and 3# aerogel. (a)XPS total spectrum; (b)C1s spectra of CNF aerogel; (c)C1s spectra of 3# aerogel; (d)Si2p spectra of 3# aerogel

2.3 隔热性能分析

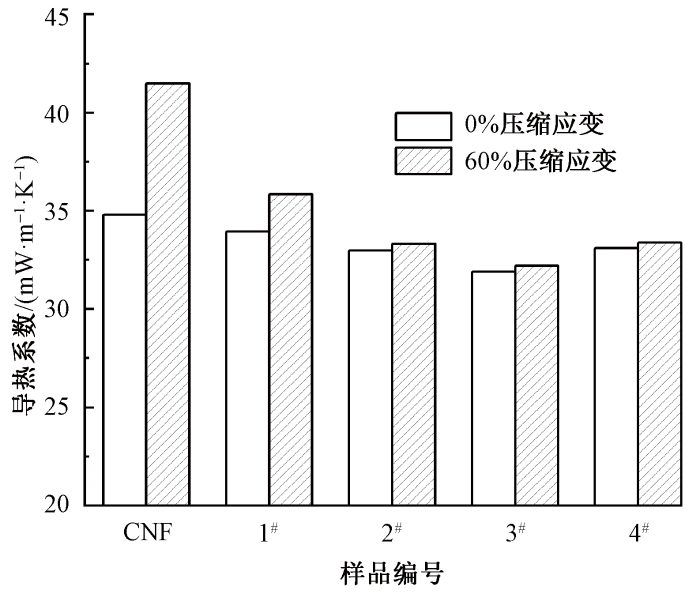

表1示出CNF气凝胶和CNF/BTMSE复合气凝胶的物理性能参数。可知:CNF气凝胶在室温下的导热系数为34.80 mW/(m·K);当CNF与BTMSE的质量比分别为4∶1、2∶1、2∶3、2∶5时,CNF/BTMSE复合气凝胶的导热系数先降低后升高;3#气凝胶的导热系数最小,为31.9 mW/(m·K)。

表1 CNF气凝胶和CNF/BTMSE复合气凝胶的物理性能

Tab.1

| 样品 编号 | 密度/ (mg·cm-3) | 孔隙率/ % | 平均孔 径/μm | 导热系数/ (mW·m-1·K-1) |

|---|---|---|---|---|

| CNF | 10.76 | 98.85 | 44.2 | 34.80 |

| 1# | 12.36 | 98.76 | 40.5 | 33.94 |

| 2# | 14.43 | 98.54 | 27.6 | 32.99 |

| 3# | 20.12 | 98.15 | 19.0 | 31.90 |

| 4# | 25.15 | 96.75 | 18.1 | 33.10 |

气凝胶的导热系数由固体传导、气体传导、热对流、热辐射共同决定,对于CNF/BTMSE复合气凝胶来说,其具有密度低、孔隙率高等特点,具有很低的固体含量,内部充满大量空气,而空气是很好的绝热体,使得气凝胶具有低的导热系数。此外,平均孔径的降低也有利于阻隔空气流动,降低空气热导率。总之,多孔结构、高孔隙率和低密度共同作用导致CNF/BTMSE气凝胶具有优越的隔热保温性能。BTMSE的引入使气凝胶内部形成致密多孔的交联网络结构,且孔径较纯CNF气凝胶有所降低,孔隙堆积限制了气体热传导和热对流,因此,气体热传导占主导地位;随着BTMSE添加量的继续增加,气凝胶体积密度持续增加,气凝胶孔隙率下降,交联网络更加致密,此时固体热传导增加,固体热导率占据主导地位,故气凝胶导热系数呈现先降低后增加的趋势[10]。

图6

图7

图7

气凝胶在0%和60%应变压缩前后导热系数

Fig.7

Thermal conductivity of aerogel at 0% and 60% compressive strain

可看到,受到60%压缩应变后,CNF气凝胶导热系数从34.80 mW/(m·K)增加到41.90 mW/(m·K),3#气凝胶的导热系数从31.90 mW/(m·K)增加到32.21 mW/(m·K),增加幅度远远小于CNF气凝胶,说明经BTMSE改性后的气凝胶有良好的隔热稳定性,在受到外力冲击后仍能保持原有的隔热性能。这是因为相比于CNF气凝胶,3#气凝胶具有良好的回弹性,被压缩后可迅速恢复,孔洞结构不会遭到破坏;CNF气凝胶被压缩后孔洞坍塌而形成致密的结构,从而导致导热系数增加。

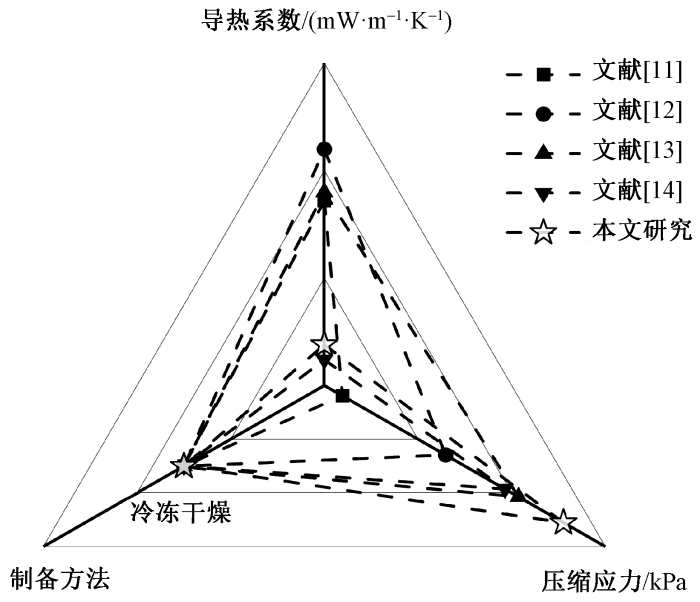

图8

图8

与已报道的纤维素基气凝胶材料的隔热和力学性能比较

Fig.8

Comparison with reported thermal insulation and mechanical properties of cellulose-based aerogel materials

2.4 力学性能分析

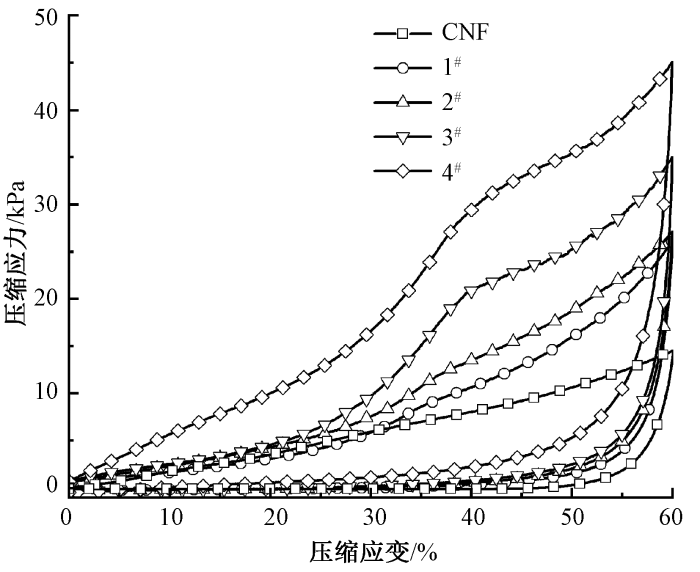

图9

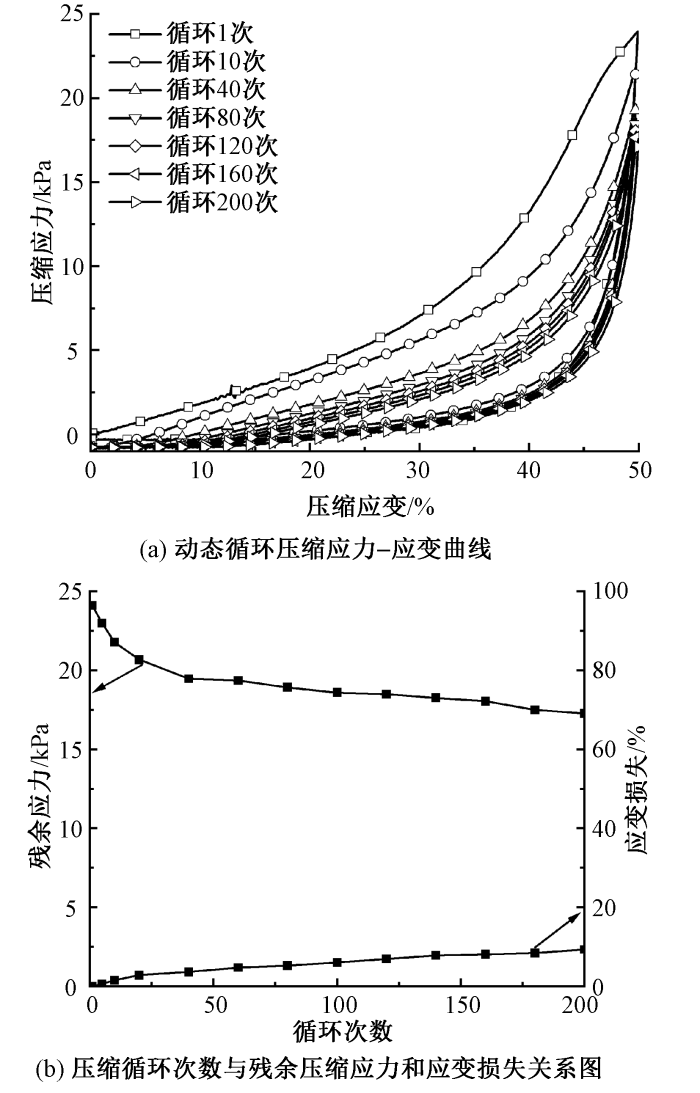

图10

图10

3#气凝胶的力学稳定性

Fig.10

Mechanical stability of 3# aerogel. (a)Dynamic cyclic compressive stress-strain diagram;(b) Relationship between number of compression cycles and loss of residual compressive stress and strain

由图9可知,在形变为60%时,CNF、1#、2#、3#、4#气凝胶的应力分别为26.1、27.2、34.8、45.1 kPa。可知,气凝胶的最大压缩应力虽然不尽相同,但曲线整体呈现相似的3段式变化趋势:首先是线性弹性形变区,主要是由片状纤维膜的弹性变形造成的;然后是缓慢上升区,曲线的斜率处于相对平稳状态,这是因为孔洞的塌陷造成应力上升速率缓慢;最后是快速增长区,在应变>50%时,应力会呈现迅速增大的趋势,这是因为气凝胶孔洞已经被压缩成致密状态。

在压缩形变为60%时,CNF、1#、2#、3#、4#气凝胶的应变恢复率分别为21.3%、74.2%、94.5%、97.6%、96.1%。可知,CNF/BTMSE气凝胶的应力随着BTMSE添加量的增加逐渐增大,形变恢复率逐渐增大并趋于稳定。这是因为BTMSE水解后,与纤维素上羟基缩聚产生共价交联,增强气凝胶骨架强度的同时使CNF纤维从非弹性材料变成弹性材料,因此在受到外力压缩时具有一定的抗压缩强力,以及外力撤去后的回弹性。当CNF与BTMSE质量比为2∶3时,3#气凝胶在60%形变下的最大压缩强力为34.8 kPa,是CNF气凝胶在同等压缩形变时强力的2.9倍,且具有97%的形变恢复率。

由图10可知:在应变为50%时,200次压缩循环后3#气凝胶的残余压缩应力为7.3 kPa,与原始应力值相比,仅损失约22.1%;同时可保持初始高度的90.4%,应变损失不足10%。证明3#气凝胶具有较好的力学性能和循环稳定性。

3 结论

本文通过硅烷偶联剂水解缩聚改性、冷冻干燥一步法制得了纳米纤维素纤维/双硅烷偶联剂1,2-二(三甲氧基硅基)乙烷(CNF/BTMSE)气凝胶,改善了纤维素气凝胶回弹性不好、力学性能不足的问题,且力学强力和回弹性的提升也避免了气凝胶受力坍塌隔热性下降的问题,经研究得到如下主要结论。

1)通过BTMSE改性和冷冻干燥技术,构筑了类蜂窝状孔洞结构的CNF/BTMSE复合气凝胶,较CNF气凝胶具有更为规整的孔洞结构,且孔径更小。

2)当CNF和BTMSE质量比为2∶3时,硅烷化改性后的3#气凝胶在60%压缩应变下应力达到 34.8 kPa, 50%应变下循环压缩200次应变仅损失9.7%,具有良好的压缩强力和力学稳定性。

3)得益于硅烷改性,受到60%压缩应变后,CNF气凝胶导热系数从34.80 mW/(m·K)增加到41.90 mW/(m·K), 增幅约20%;CNF与BTMSE质量比为2∶3的气凝胶导热系数从31.90 mW/(m·K)增加到32.21 mW/(m·K),增幅不足1%,远小于CNF气凝胶。表明CNF/BTMSE复合气凝胶在硅烷改性后具有良好的隔热稳定性。

参考文献

Ice-templated MXene/Ag epoxy nanocomposites as high-performance thermal management materials

[J].

Hydrophobic modification on surface of chitin sponges for highly effective separation of oil

[J].

Cellulose nanofibril aerogels: synergistic improvement of hydrophobicity, strength, and thermal stability via cross-linking with diisocyanate

[J].

Highly flexible cross-linked cellulose nanofibril sponge-like aerogels with improved mechanical property and enhanced flame retardancy

[J].

DOI:S0144-8617(17)31118-9

PMID:29111059

[本文引用: 1]

Cellulose nanofibril (CNF) aerogel is highly flammable and its mechanical strength is very soft, which is unfavourable due to safety concerns and impractical when used as the thermal insulation material. In this work, we used N-methylol dimethylphosphonopropionamide (MDPA) and 1,2,3,4-butanetetracarboxylic acid (BTCA) as co-additives and then prepared lightweight flame resistant CNF sponge-like aerogels via an eco-friendly freeze-drying and post cross-linking method. The CNF/BTCA/MDPA aerogel exhibited a better flame retardant performance, outstanding self-extinguishing behaviour and significantly increased char residue (by as much as 268%) compared with the neat CNF aerogel. Meanwhile, the resilience of the aerogel samples improved significantly as the flexibility decreased slightly. Furthermore, the aerogel samples still exhibited excellent thermal insulating properties with thermal conductivity as low as 0.03258W/(m k). The combination of these characteristics makes the CNF-based aerogel a promising insulation candidate for thermal protective equipment (e.g., fire-protection clothing or advanced spacesuit elements) in the future.Copyright © 2017 Elsevier Ltd. All rights reserved.

Highly compressible, anisotropic aerogel with aligned cellulose nanofibers

[J].

DOI:10.1021/acsnano.7b04246

PMID:29257663

[本文引用: 1]

Aerogels can be used in a broad range of applications such as bioscaffolds, energy storage devices, sensors, pollutant treatment, and thermal insulating materials due to their excellent properties including large surface area, low density, low thermal conductivity, and high porosity. Here we report a facile and effective top-down approach to fabricate an anisotropic wood aerogel directly from natural wood by a simple chemical treatment. The wood aerogel has a layered structure with anisotropic structural properties due to the destruction of cell walls by the removal of lignin and hemicellulose. The layered structure results in the anisotropic wood aerogel having good mechanical compressibility and fragility resistance, demonstrated by a high reversible compression of 60% and stress retention of ∼90% after 10 000 compression cycles. Moreover, the anisotropic structure of the wood aerogel with curved layers stacking layer-by-layer and aligned cellulose nanofibers inside each individual layer enables the wood aerogel to have an anisotropic thermal conductivity with an anisotropy factor of ∼4.3. An extremely low thermal conductivity of 0.028 W/m·K perpendicular to the cellulose alignment direction and a thermal conductivity of 0.12 W/m·K along the cellulose alignment direction can be achieved. The thermal conductivity is not only much lower than that of the natural wood material (by ∼3.6 times) but also lower than most of the commercial thermal insulation materials. The top-down approach is low-cost, scalable, simple, yet effective, representing a promising direction for the fabrication of high-quality aerogel materials.

Super-elastic and highly hydrophobic/superoleophilic sodium alginate/cellulose aerogel for oil/water separation

[J].

GERMAN Salazar Alvarez,Thermally insulating and fire-retardant lightweight anisotropic foams based on nanocellulose and graphene oxide

[J].

DOI:10.1038/nnano.2014.248

PMID:25362476

[本文引用: 1]

High-performance thermally insulating materials from renewable resources are needed to improve the energy efficiency of buildings. Traditional fossil-fuel-derived insulation materials such as expanded polystyrene and polyurethane have thermal conductivities that are too high for retrofitting or for building new, surface-efficient passive houses. Tailored materials such as aerogels and vacuum insulating panels are fragile and susceptible to perforation. Here, we show that freeze-casting suspensions of cellulose nanofibres, graphene oxide and sepiolite nanorods produces super-insulating, fire-retardant and strong anisotropic foams that perform better than traditional polymer-based insulating materials. The foams are ultralight, show excellent combustion resistance and exhibit a thermal conductivity of 15 mW m(-1) K(-1), which is about half that of expanded polystyrene. At 30 °C and 85% relative humidity, the foams retained more than half of their initial strength. Our results show that nanoscale engineering is a promising strategy for producing foams with excellent properties using cellulose and other renewable nanosized fibrous materials.

硅烷偶联剂改性纳米纤维素气凝胶的制备及其表征

[J].

Preparation and characterization of nanocellulose aerogel modified by silane coupling agent

[J].

Silica@cellulose hybrid aerogels for thermal and acoustic insulation applications

[J].

Recycling of pineapple leaf and cotton waste fibers into heat-insulating and flexible cellulose aerogel composites

[J].

Eco-friendly thermally insulating cellulose aerogels with exceptional flame retardancy, mechanical property and thermal stability

[J].

京公网安备11010502044800号

京公网安备11010502044800号